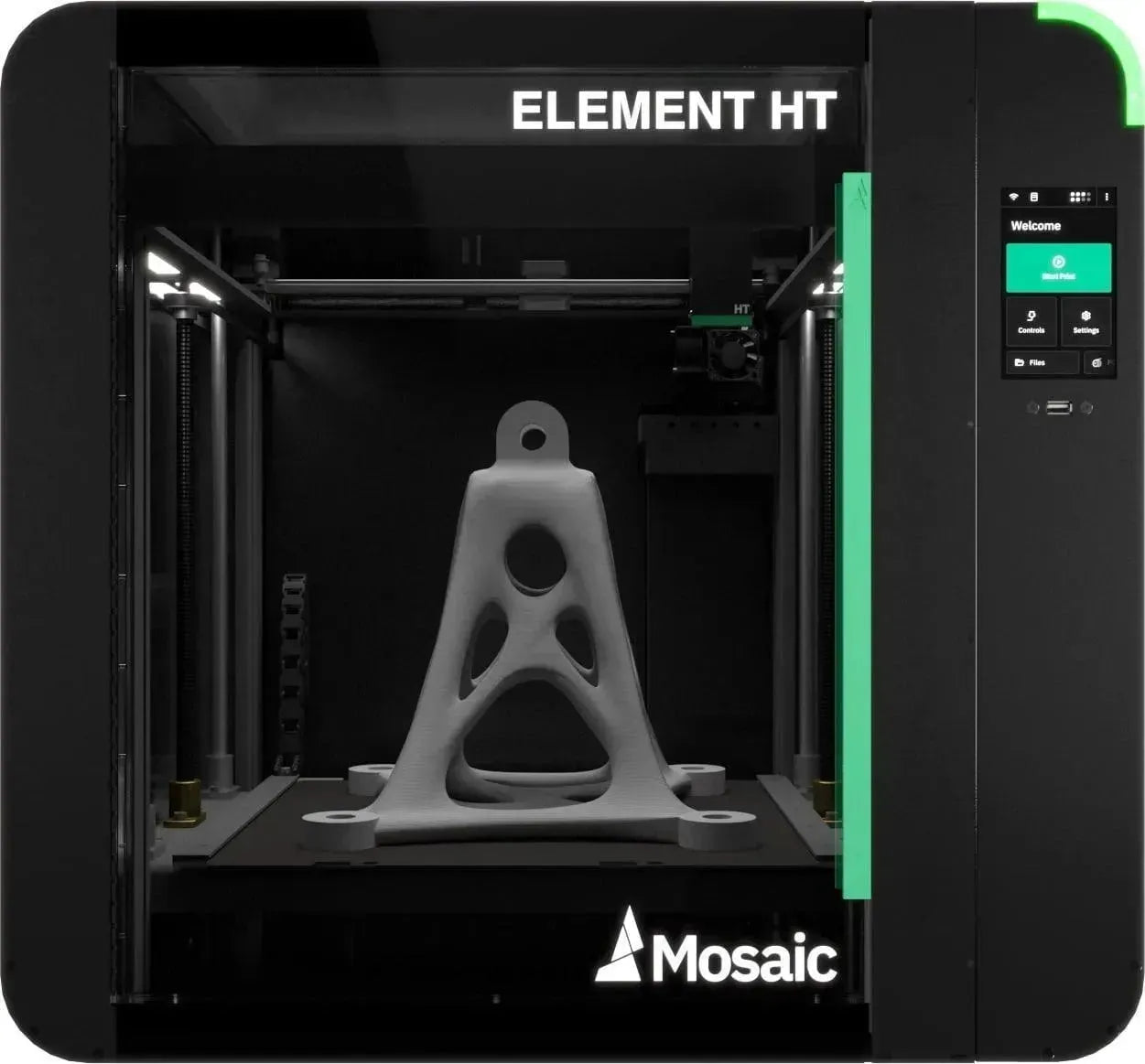

Mosaic Element HT

Mosaic Element HT

Couldn't load pickup availability

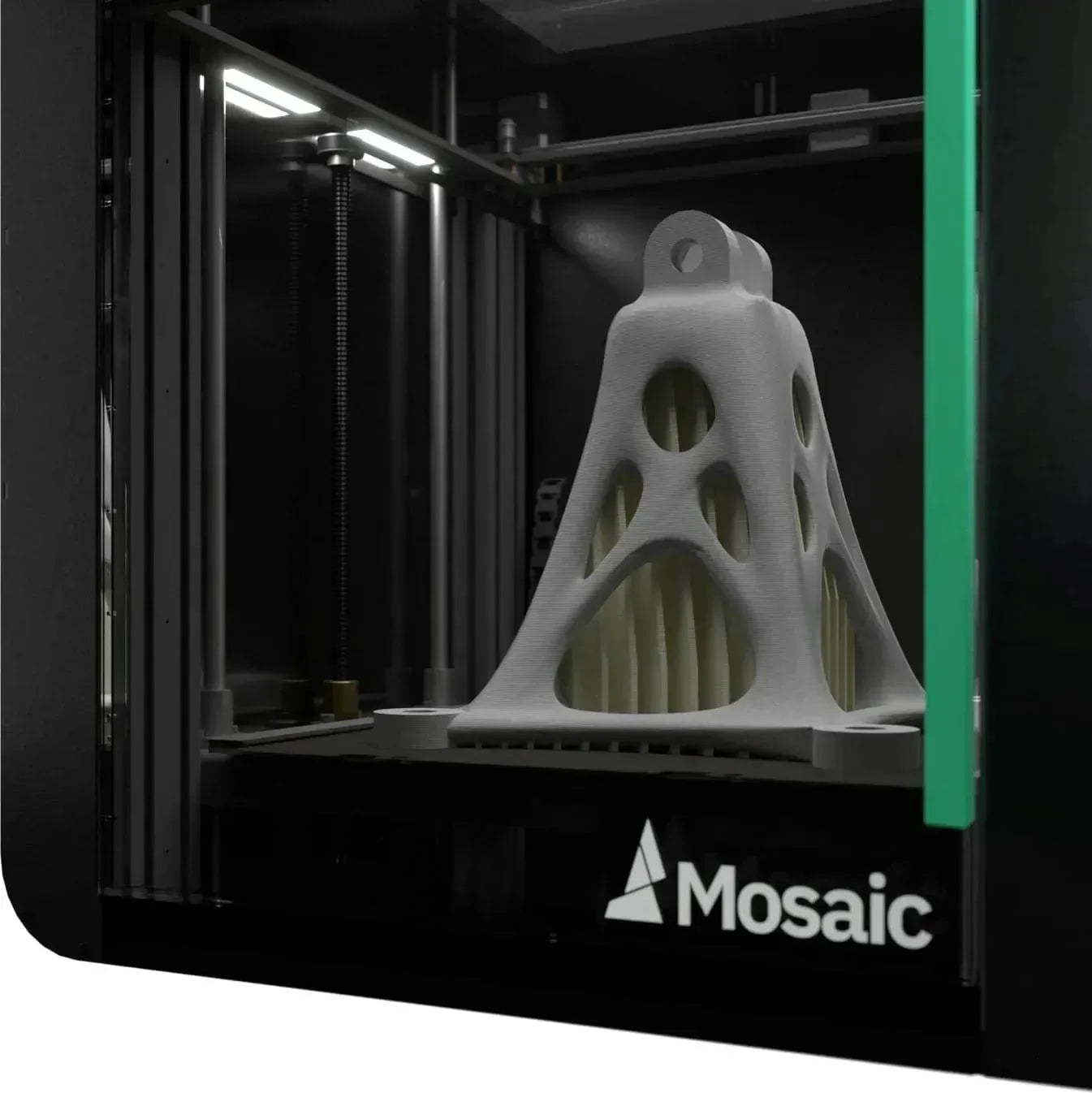

The next generation of industrial-quality desktop 3D printers

Element HT includes all the benefits of Element, but also has the ability to print technical filaments at high temperatures.

Workflow automation also improves the efficiency of Element HT.

Main features:

- Max hot-end temperature 500°C, Max heated bed temperature 120°C, Max print chamber temperature 90°C

- Construction volume 355 x 355 x 355 mm

- Integrated Palette X - Print up to 8 colors / materials

- Modular extruder

- Cloud with CANVAS slicing software

- LED display of printing status

- HIWIN Linear Guides

- Core XY System

- Trinamic Stepper Driver

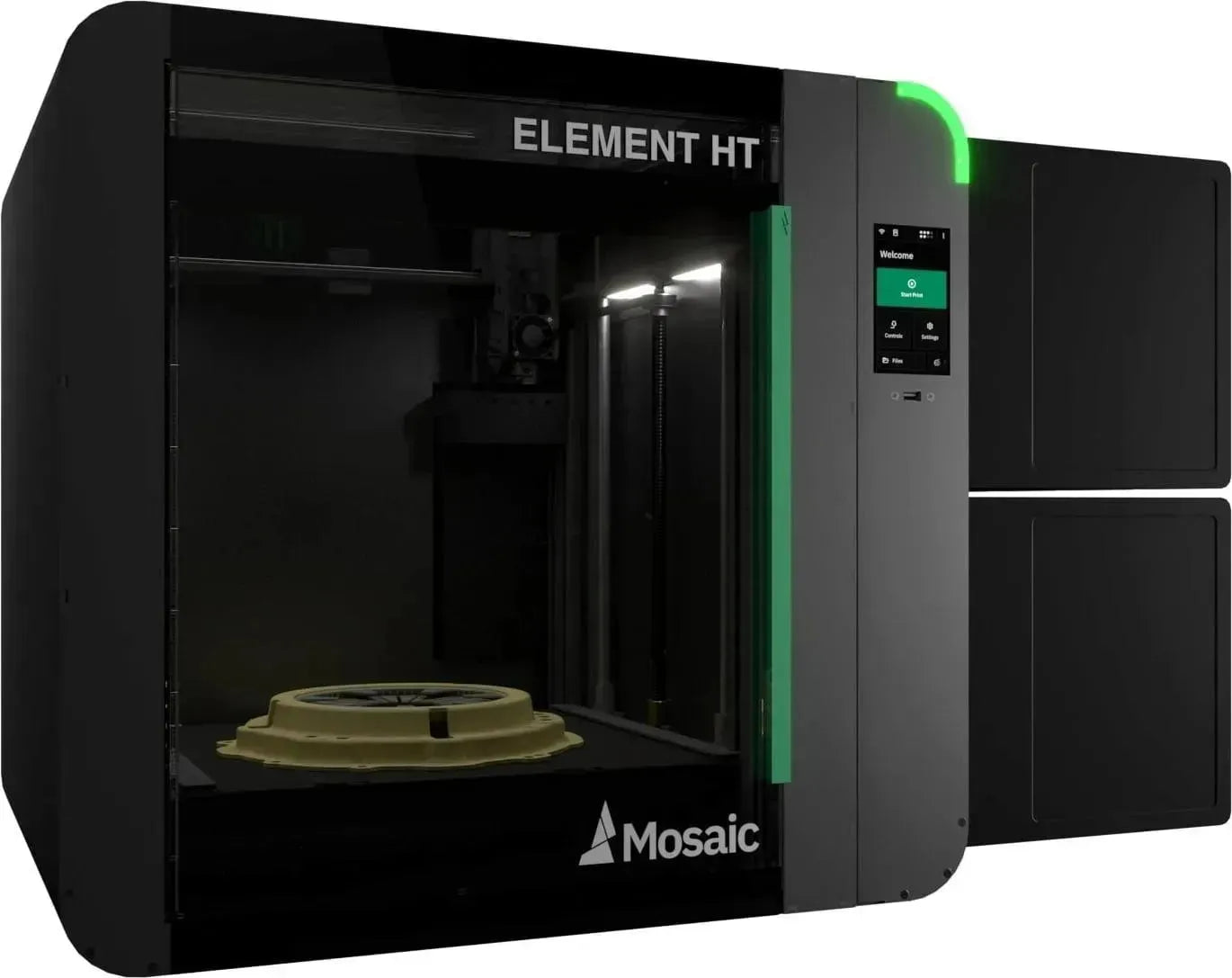

Multi-material management and automated workflow

A built-in Palette X in the 3D printer allows you to print up to 8 different materials and colors in one model. Using CANVAS slicing software, the Mosaic Material Pod (material container) and Mosaic Filaments, the entire printing process and filament management are automated.

The Element 3D printer can automatically process and handle the following Mosaic filaments:

- Nylon and Nylon CF

- ABS

- PLA

- PETG

- TPU

- PVA

- HIPS

- PEEK

- PEKK

- Ultem 9085

Element can also print filaments from other manufacturers, but without the benefit of automatic filament feeding.

Each Material Pod contains a motor that pushes filament from the container to the Palette X and print head. Unlike external Palette devices, the Palette X does not combine materials. The Element printer, together with the Palette X, has full control over material management, which leads to higher print quality and less material waste.

The 3D printer is connected to CANVAS via the cloud, a software that can be used to create, edit and organize multi-material models. Sending to the printer is extremely simple and does not take much time.

Large build volume

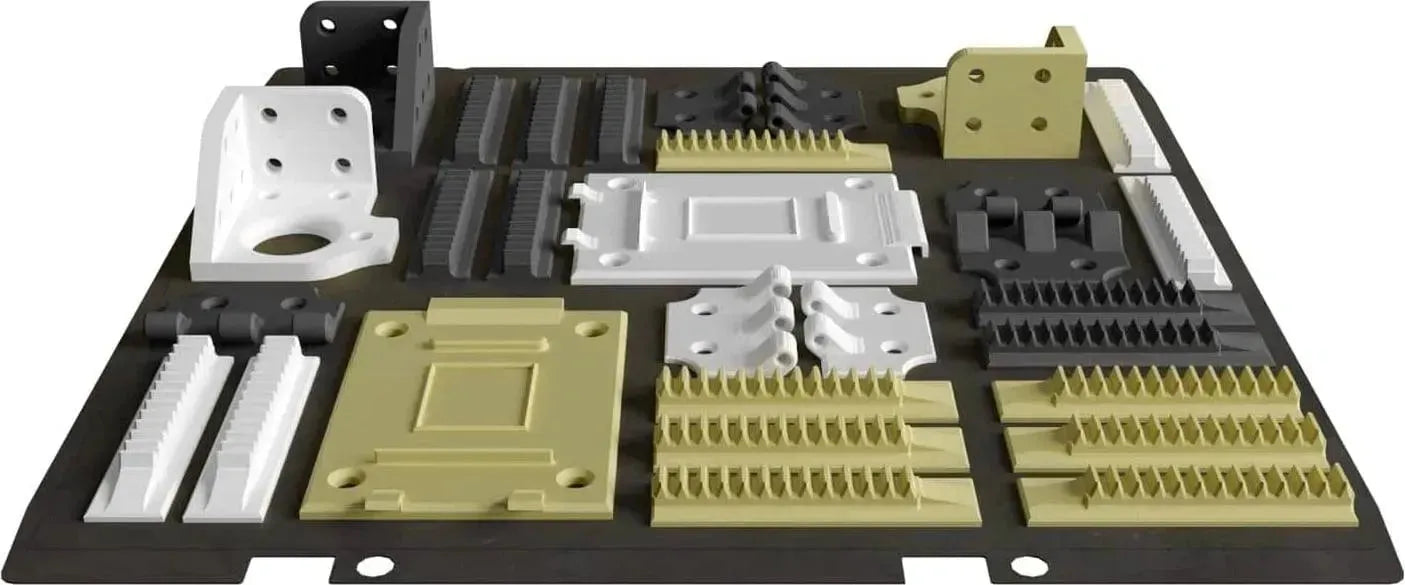

With a build volume of 355 x 355 x 355 mm, the 3D printer is suitable for creating large models or printing multiple parts at once.

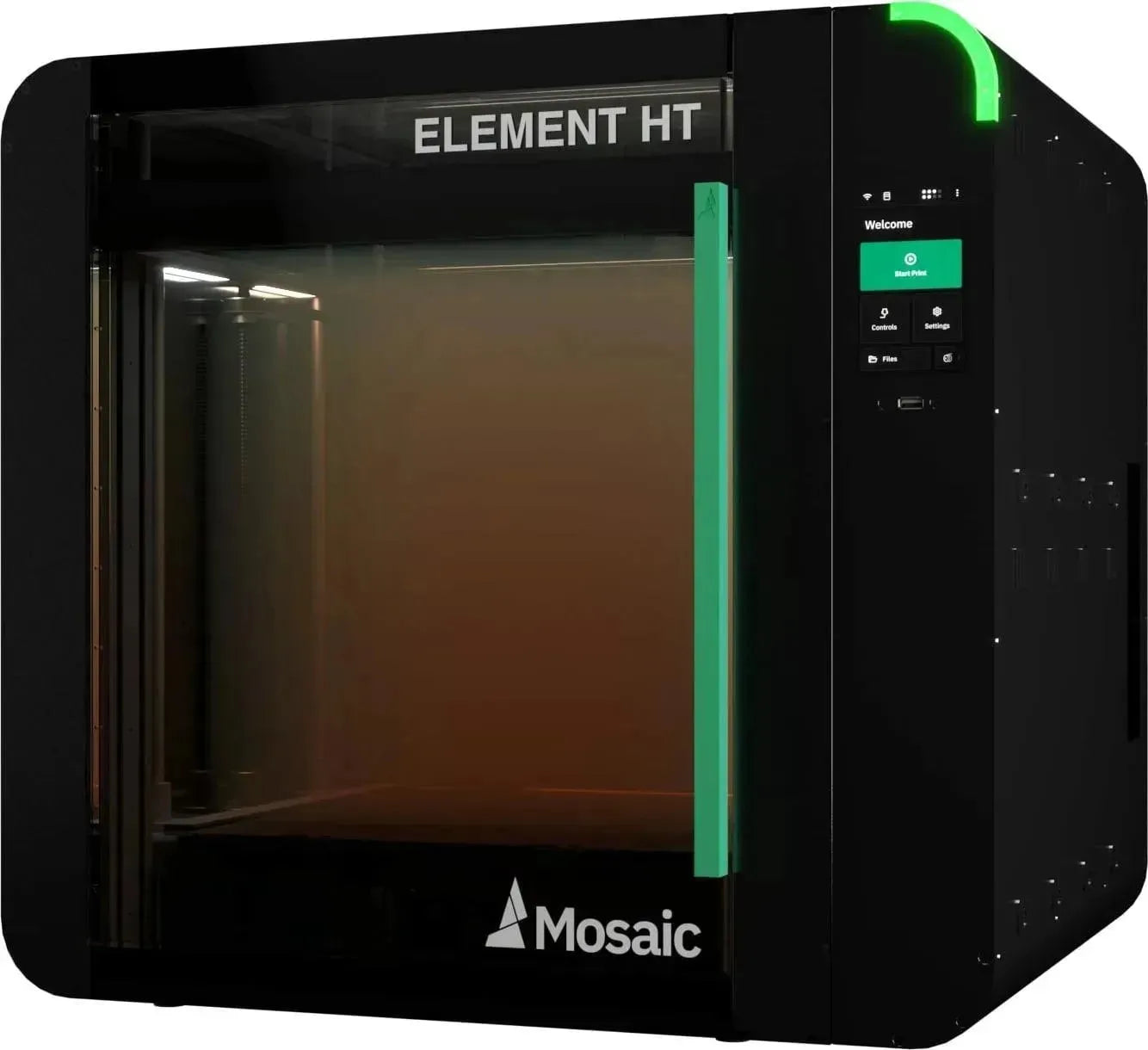

Heated print chamber

The actively heated print chamber reaches 90°C, thus supporting the printing process of materials such as PEEK, PEKK and Ultem 9085.

Modular extruder

A modular design makes it easy to remove and reattach the printhead for replacement or repair.

Intuitive user experience

Element's cloud connectivity to CANVAS streamlines the user experience, allowing complete control of print projects directly from the printer.

What's included:

- 2 type I beds

- 2 capsules of material

- 750cc PLA

- Matrix 750cc

- Quick Guide

- USB stick

- 2 glue sticks

- Tool bag

- Mosaic screwdriver 2mm

- 2.5mm Allen key

- 3mm Allen key

- 4mm Allen key

Technical specifications:

- Dimensions: 911mm x 613mm x 633mm (with 8 material pods attached)

- Net weight: 43 kg (95 lbs) (printer, no material pods attached)

- Gross weight: 57 kg (125 lbs) (with packaging, 2 material pods in box)

- Printing Technology: Enhanced Fused Filament Fabrication (FFF) with Mosaic's patented Series Enabled Multi-Material Extrusion (SEME)

- Build volume: 355mm x 355mm x 355mm (14” x 14” x 14”)

- Construction: Durable, all metal movement systems

- Power Input: 100V - 240V AC, 50/60Hz, dedicated circuit required

-

Level resolution: 20-320 microns

-

XYZ Resolution: 12.5μm, 12.5μm, 0.4μm (X,Y,Z)

-

Maximum speed (travel): 200mm/s

-

User Interface: 5" color touch screen or remote access from Canvas

-

Monitoring: Live camera inside the room

-

Status indication: RGB light stack

-

Nozzle: 0.4mm hardened steel nozzle

-

Compatible Models: 0.4 Print Head, 0.4 HT Print Head

- Maintenance: Modular extruder, removable without tools in < 60 seconds

-

Build speed: 100mm/s

-

Build Plate: Various coatings on the removable spring steel build plate for quick and easy build plate changes

-

Heated bed: Maximum 120°C

-

Thermal Chamber: Heated, up to 80°C

-

Maximum nozzle temperature: 500°C

-

Air Filtration: HEPA filter to remove up to 99.7% UFP or BOFA filter External Fume Extraction: Integrated 50mm (2 inch) inlet and outlet for optional external fume extraction connection (purchased separately)

-

Operating sound: < 60 dBA

- Sensors: Filament homing, Filament movement, Ambient T , Hotend T , Cold T

-

Software provided: Canvas. Free print preparation software with optional paid features

-

Supported Operating System: MacOS, Windows and Linux

- Connectivity/File Transfer: Wi-Fi, LAN, USB port

- Supported materials: Mosaic PLA, Mosaic PETG, Mosaic Origin, Mosaic Matrix, Dissolve LT, Mosaic ABS, Mosaic Breakaway LT. Mosaic PEEK, Mosaic PEKK, Mosaic Ultem 9085, Mosaic ESD. TPE not supported.

-

Third-party Filament Support: The system is open to support third-party materials, and any materials that fit into Mosaic’s Material Pod will be able to access material automation and multi-material 3D printing.

-

Filament Cartridges: Material Pod v1

-

Filament Containment: Mosaic Pods are reusable, environmentally sealed dry boxes (1 pack of two Material Pods is included in the basic Element HT configuration)

-

Filament Housings: 8 Mosaic Material Pod Receivers

-

Filament loading: Automatic filament loading, filament retraction

-

Filament sensors: Filament homing, Filament consumption meter, Filament relative humidity, Filament temperature

-

Filament Changer Model: Palette X - Automated material server module including filament unit, material cutter, filament homing and filament measurement systems

-

Nozzle cleaning: Integrated nozzle cleaning cloth for materials up to 300°C, wire nozzle cleaning brush and integrated high-temperature cleaning pad for materials up to 500°C

- Transition Container: Removable container with 38mm x 264mm x 253mm storage space

Shipping and Warranty

Shipping and Warranty

All products available in stock will be delivered with an average timing of 24/48 hours.

Italy warranty with dedicated consulting support, contact us!

Share

-

Free shipping, return in 14 days *.

DisclosureFree express shipping for orders over € 499.

* For return terms and conditions, please visit our returns and refunds policy.

-

-

Are you a professional or a company?

Contact usYou can ask us for an invoice for your purchases! All the prices of our products already include VAT.

-

Do you have the teacher's card?

Contact usProceed with checkout and select "Teacher's Card" as the payment method. Requests?