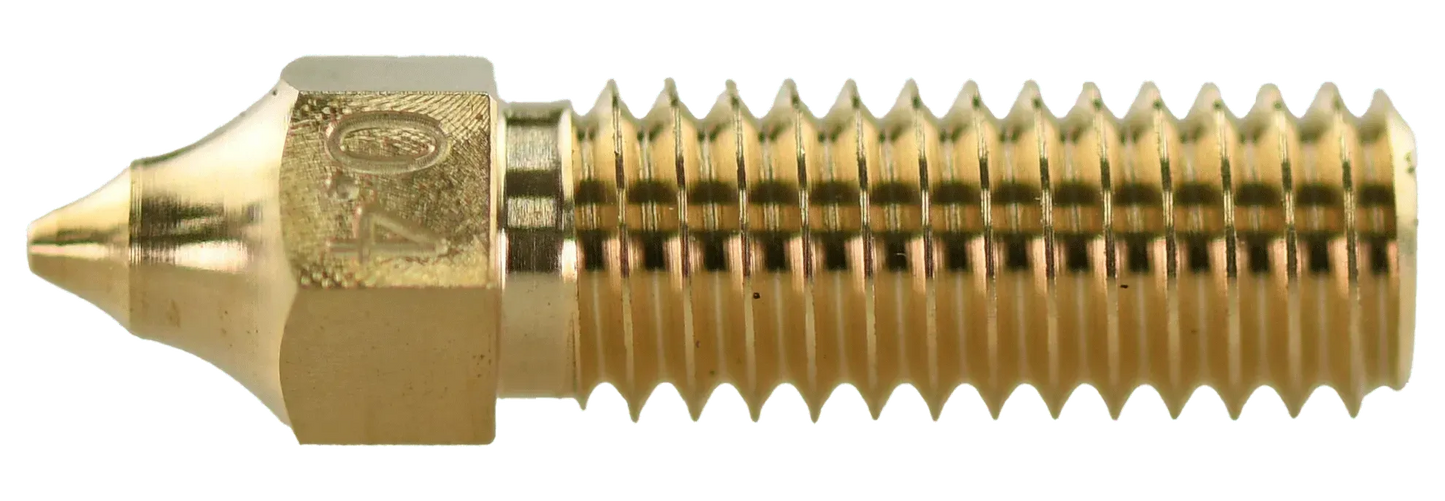

PRIMACREATOR CREALITY K1/ K1 MAX BRASS NOZZLE 0.4 MM - 1pc

PRIMACREATOR CREALITY K1/ K1 MAX BRASS NOZZLE 0.4 MM - 1pc

Couldn't load pickup availability

PrimaCreator Premium Nozzles are a set of replacement nozzles that can make more of a difference in your results than you might think. Having a high quality nozzle is like having a sharp pencil, you need it to get a great print.

Characteristics

- High quality nozzle

- State-of-the-art factory

- Tolerance is less than ± 0.01mm

High quality

All PrimaCreator nozzles are made of the highest quality brass or steel (depending on the type) and are completed in a state-of-the-art factory. All nozzles are produced with a tolerance of less than ± 0.01 mm. This means that the filament will have a very smooth and clear surface during extrusion, which of course results in better prints.

After this process, the material passes through an ultrasonic cleaning bath and is then cleaned again and protected from surface oxidation. The nozzle will now take shape with millimeter precision, the tolerance is less than ± 0.01 mm.

The process of removing sharp edges from the nozzles is a very important step as they make up a large part of the result. If too many sharp edges are left on the nozzle, the nozzle will be more prone to clogging. So it is essential that the nozzle is very smooth and clean before being used. In each batch a few nozzles are selected and cut in half to ensure that every specification is met and the surface is in perfect condition.

The nozzles are then checked one last time and individually packed in a protective box, ready for shipment.

Dimensions

- 0 = 0.20 mm

- 3 = 0.40 mm

- 4 = 0.60 mm

- 5 = 0.80 mm

Recommendations

For best results and print quality, we strongly recommend re-leveling the build plate after using a new nozzle. Please note that a PrimaCreator nozzle may be compatible with your printer, but the distance between the nozzle and the print bed needs to be adjusted.

The process

The process of making a PrimaCreator nozzle starts with a selected high-quality material. When the material reaches the factory, an optical check is first carried out on the material that will be used for each batch of nozzles. Then it is time to fix the material, in other words, to turn it into a long rod. In our process this is done only once, in many other (cheaper) cases, this process has to be repeated several times, often up to 3-4 times and still the same results are not achieved.

Suitable for K1 / K1Max

Shipping and Warranty

Shipping and Warranty

All products available in stock will be delivered with an average timing of 24/48 hours.

Italy warranty with dedicated consulting support, contact us!

Share

-

Free shipping, return in 14 days *.

DisclosureFree express shipping for orders over € 499.

* For return terms and conditions, please visit our returns and refunds policy.

-

-

Are you a professional or a company?

Contact usYou can ask us for an invoice for your purchases! All the prices of our products already include VAT.

-

Do you have the teacher's card?

Contact usProceed with checkout and select "Teacher's Card" as the payment method. Requests?