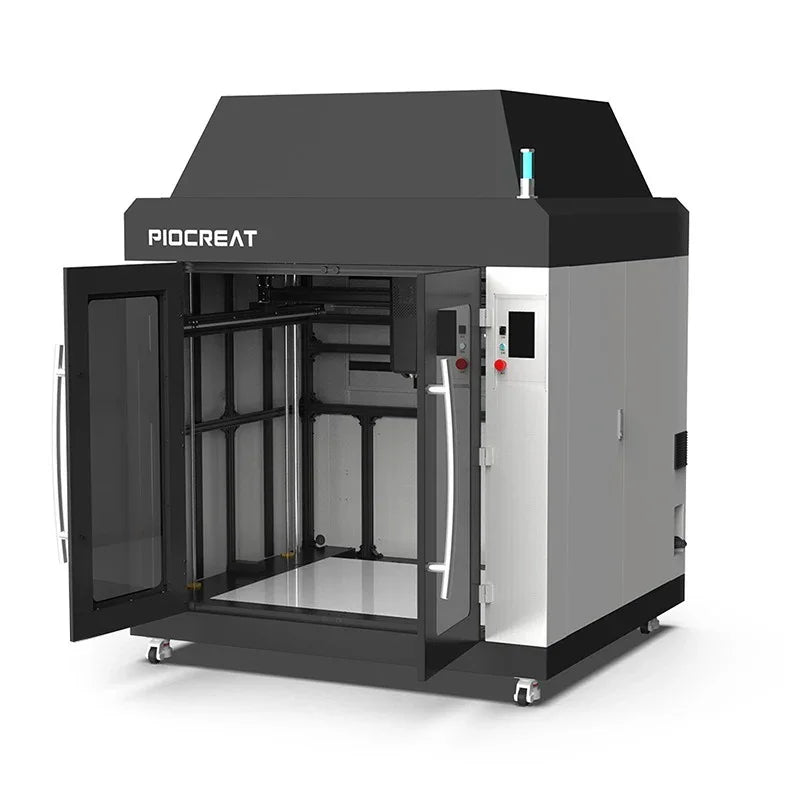

PIOCREAT G12 GRAIN 3D PRINTER

PIOCREAT G12 GRAIN 3D PRINTER

Couldn't load pickup availability

The Piocreat G12 industrial pellet 3D printer is a large-scale machine suitable for various industrial applications. It has a fully enclosed build chamber with a constant temperature of 60°C and a huge build volume of 1200 x 1000 x 1000 mm, which allows for printing large models. The maximum print speed of 100 mm/s makes short print times important for industrial production runs.

Characteristics:

- High-speed, high-precision printing

- Room temperature control

- Screw nozzle design

- BL Touch Auto Leveling

- Multi-pellet printing

- Super large format

The Piocreat G12 industrial pellet 3D printer is a large-scale machine suitable for various industrial applications. It has a fully enclosed build chamber with a constant temperature of 60°C and a huge build volume of 1200 x 1000 x 1000 mm, which allows for printing large models. The maximum print speed of 100 mm/s makes short print times important for industrial production runs.

FGF Technology

Piocreat G12 is an industrial-grade 3D printer based on FGF (fused granule fabrication) technology, a type of material extrusion AM process, similar to FDM printing. FGF 3D printers work with thermoplastic materials in the form of pellets or granules, which are loaded into a hopper, fed to the screw extrusion system where they heat up and the homogeneous molten plastic mass is extruded through a nozzle to build a model. Because the plastic filaments used for FDM 3D printing are made of pellets, using the pellets directly to build parts makes FGF printing incredibly cost-effective for many industrial applications.

Screw nozzle

Self-developed screw nozzle design, with a diameter of 0.6-6mm, maximum temperature 450 °C, the consumables melt completely and come out smoothly.

Super large format

The printing size of 1200 x 1000 x 1000mm can meet the printing needs of large-scale industrial parts and final products.

Production-level print quality

According to the needs of industry users, select the corresponding materials and print industrial parts similar to injection molding.

Room temperature control

Stable structure, reduced vibration, 60°C chamber temperature, better printing and forming effect, and higher toughness of printed parts.

Automatic intelligent leveling

Multi-point auto leveling system to ensure no wrapping during printing and print forming speed up to 99%

Rapid heating platform

Silicon heating design, fast heating, reduce printing waiting time, convenient printing; The power density per square is 0.48 W/cm; It is heated to 150°C and cooked in air for 5-8 minutes.

Why choose FGF pellet 3D printer?

- Making molds: save time and reduce costs

- Art of sculpture: Mainly used in the production of artistic creations, digital sculptures, landscape models, etc.

- Education and Research: 3D printing products teaching, materials science research, etc.

- Industrial parts: applied to structural part models, industrial figures, industrial parts, etc.

Parameter

-

- Print size: 1200*1000*1000 mm

- Molding technology: FGF

- Nozzle number: single nozzle

- Slice thickness: 0.2~2mm

- Nozzle Diameter: 0.6~4mm (6mm customizable)

- Particle diameter: 2~5mm

- Filament: PLA、PETG、ABS、PC、PA、HDPE、TPU、EVA、PC+ABS、PA+Fiber、WPC、MQP-S+PA12、EVA foam board

- File format: STL, OBJ, AMF, 3DMF

- File Transfer: USB/Memory Card

- Bed temperature: ≤150℃

- Nozzle temperature: ≤450℃

- Language: English/Chinese

- Computer Operating System: Windows XP/7/8/10 MAC/Linux

- Printing speed: 80~100mm/s

- Rated power: 6500 W

- Machine dimensions: 2200x1780x2250 mm

| Construction and technical details | |

| Nozzle threading/mounting | Pius M7 |

| Maximum nozzle temperature | 450°C |

| Open filament system | YES |

| Extruder type | Direct drive |

| Recommended maximum print speed | 100 mm/s (depends on material) |

| Build volume | Dimensions: 1200x1000x1000 mm |

| Maximum build plate temperature | 150°C |

| Build plate material | tempered glass |

| Assembling the build plate | fixed |

| Build plate leveling system | automatic |

| Building the room during the process | Open or Closed |

| Heated construction chamber | Yes, maximum 60°C |

| Closed filament chamber | YES |

| Number of extruders | 1 |

| Installation Space / Requirements | |

| Overall dimensions | Dimensions: 2200mm x 1780mm x 2250mm |

| Net weight | 850 kilos |

| Operating ambient temperature | Temperature: 5°C to 40°C |

| Maximum power consumption | 7000 Watt |

| Voltage | AC: 230V (50Hz) |

| Equipment | |

| Emergency stop | YES |

| Hepa filter | YES |

| Filament run out sensor | YES |

| Power Loss Protection | YES |

| Touch screen | YES |

| Connection | |

| SD card | YES |

| USB port | YES |

| Wireless network | NO |

| Precision | |

| Layer height | From 0.2 to 2.4 mm |

| Shipping | |

| Shipping box | Dimensions: 1770mm x 1960mm x 2150mm |

| Gross weight | 1050 kilos |

Shipping and Warranty

Shipping and Warranty

All products available in stock will be delivered with an average timing of 24/48 hours.

Italy warranty with dedicated consulting support, contact us!

Share

-

Free shipping, return in 14 days *.

DisclosureFree express shipping for orders over € 499.

* For return terms and conditions, please visit our returns and refunds policy.

-

-

Are you a professional or a company?

Contact usYou can ask us for an invoice for your purchases! All the prices of our products already include VAT.

-

Do you have the teacher's card?

Contact usProceed with checkout and select "Teacher's Card" as the payment method. Requests?