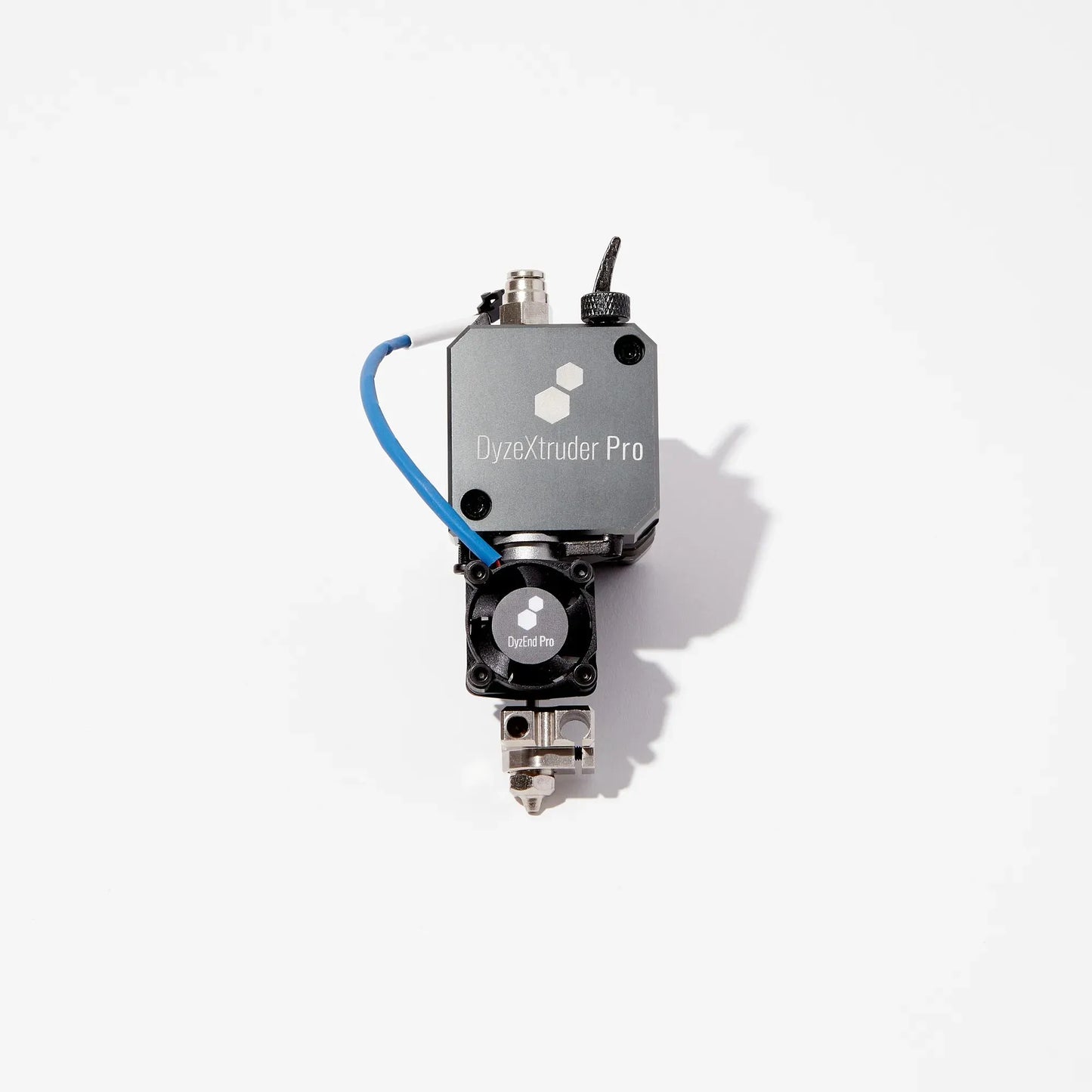

DyzEND Pro Kit + DyzeXtruder Pro 1.75mm

DyzEND Pro Kit + DyzeXtruder Pro 1.75mm

Couldn't load pickup availability

Dyze Design Pro Series Extruder and Hotend Kit: High performance, high speed, high flow rate, high temperature and high thrust force. Equipped with ultra wear-resistant tungsten carbide nozzle.

The DyzEnd Pro has an extremely small form factor, making it one of the smallest hot ends on the market. It is designed with a new high-temperature heating block, a new ceramic-coated transition tube, vibration damping, reinforced sealing properties, and smaller, vibration-resistant connectors, better suited for indoor 3D printers. Additionally, the DyzEnd Pro features Dyze Design’s new ultra-wear-resistant tungsten carbide nozzle. The high thermal performance of tungsten carbide keeps the nozzle tip hot, allowing for faster printing speeds without compromising quality. Tungsten carbide offers exceptional wear resistance due to its high hardness.

The DyzeXtruder Pro is a lightweight, all-metal 3D printer extruder with one of the smallest form factors on the market—no larger than the NEMA 17 it uses, making it extremely space-efficient in a multi-extruder setup. The extruder is also more robust than ever. With improved teeth and new bearing types, the DyzeXtruder Pro can push up to 10kg (22lbs) of force. This is more than necessary for all 3D printing applications. Finally, the new rear block features cooling fins for improved heat diffusion in enclosed environments.

New High Temperature Heating Block : Steel maintains its resistance to high temperatures much better than copper or aluminum. The new block shape reduces leakage by breaking sharp edges. The coating is very slippery and easier to clean.

New Ceramic Coated Transition Tube: The DyzEnd Pro is constructed with a ceramic coated titanium transition tube. The hard coating increases wear resistance and reduces friction, allowing for easier retraction and better flow.

Fan Noise and Vibration Dampening: The small rubber spacer absorbs the vibrations generated by the fan and reduces the noise. The premium fans are equipped with ball bearings, which increases the lifespan and further reduces vibrations.

Cold-changeable nozzles: Using a special high-temperature sealing gasket and an extremely durable M10 nozzle, DyzEnd Pro is capable of changing nozzles at room temperature. No leaks, no risk of burns.

Inconel® Sealing Washer: Inconel alloys are heat resistant and can be used in extreme environments. The sealing washer easily maintains its sealing properties, even at 500 °C.

Any Temperature Sensor: Choose from a 300°C thermistor, 500°C thermistor, 500°C PT100, or 500°C K-type thermocouple sensor.

Liquid Cooling Ready: DyzEnd Pro can be easily converted to a liquid-cooled setup with Dyze Design's specialized cooling blocks.

DyzeXtruder Pro

Tool-Free HotEnd Removal: Remove the hotend from the extruder in seconds using the thumbscrew. This will loosen the spline holder and free the hotend.

Multiple mounting options: Side threads make it easy to mount; two M3 screws are included to attach the DyzeXtruder Pro to a printer, without brackets. It is also possible to mount the extruder on a panel.

Filament Guided: The guides guide the filament out of the extruder. They follow the shape of the teeth, leaving no other exits for the filament. The entire component is equipped with a low-friction coating, which increases the pushing efficiency.

Completely redesigned teeth: 35% more pushing force with rigid filaments. 25% more pushing force with flexible filaments. Plus, the filament stays round, even after over 100 passes.

Metal Gearboxes: The DyzeXtruder Pro has a gear ratio of 5.65:1. This ratio was chosen to fully utilize the potential of a very small motor, while allowing for very high thrust forces. The gears are custom-made from high-strength, hardened steel. This combination allows for low-friction operation and increased durability. The gears and bearings are designed to withstand loads of hundreds of kilograms under extreme conditions.

Dual Pinch Drive System: The dual pinch system allows for greater pushing force with less pressure on the filament. Reduces the risk of filament flattening when very detailed prints require multiple retractions.

Constant Pressure: The custom spring has been redesigned to provide optimal pressure on the filament with the new teeth. You will always get the same output flow, reducing variations due to filament changes.

Matched Included Motor: The included motor is chosen based on the maximum torque tolerated by the filaments. The motor does not wrinkle the filament and prevents any damage inside the extruder.

In the box

-

DyzEnd Pro Hotend with tungsten carbide nozzle

- Fan with connector

- DyzeXtruder Pro

- Heater with connector

- Temperature sensor with connector

-

Extension cables

- 1000mm – Fan

- 1000mm – Heater

- 1000mm – Sensor

- 1000mm stepper motor cable

- Black band

- Dyze Design brand stickers

- Additional sealing washer

- 2* M3x10 mounting screws

* Mounting bracket is not included. You can design it yourself or find inspiration from the community: https://www.yeggi.com/q/dyze/

Shipping and Warranty

Shipping and Warranty

All products available in stock will be delivered with an average timing of 24/48 hours.

Italy warranty with dedicated consulting support, contact us!

Share

-

Free shipping, return in 14 days *.

DisclosureFree express shipping for orders over € 499.

* For return terms and conditions, please visit our returns and refunds policy.

-

-

Are you a professional or a company?

Contact usYou can ask us for an invoice for your purchases! All the prices of our products already include VAT.

-

Do you have the teacher's card?

Contact usProceed with checkout and select "Teacher's Card" as the payment method. Requests?