INSPECTION WITH DRONES

WHAT IS A DRONE INSPECTION?

Cost cutting. Greater efficiency. Risk reduction.

Save "millions of euros a day"

Drones have become crucial tools for inspection - they collect accurate data securely and quickly, resulting in huge cost savings, insights and more informed decision making.

Businesses around the world have seen this potential and are harnessing the power of technology.

A drone inspection is the process of using an unmanned aircraft to evaluate an asset. In this case, the drones literally become the inspector's eyes.

Drones have the advantage of reaching places that are difficult, expensive, dangerous, alive or even impossible to reach by manned inspection teams and can be used for indoor, underground, onshore or offshore purposes.

A drone can inspect a variety of assets, such as wind turbines, building facades, railways, and crops.

Inspection drones are used in a wide range of industries, such as oil and gas, energy, agriculture, critical infrastructure, public safety and mining.

Cost savings

DJI M300 RTK and H20 allowed oil giant Shell to save $ 100,000 in a single use.

Gain in efficiency

Drones collect solar panel data over 50 times faster than manual methods.

Reliable data

Drone inspections in the energy sector provide a higher level of detail than traditional methods,

Reduced risks

“Drones increase safety and keep employees at a safe distance from hazardous areas” - Rio Tinto.

ADVANTAGES OF DRONE INSPECTIONS

How drones improve your inspection missions.

Using a drone for inspections has multiple advantages. These include:

- Risk reduction: The inspection team no longer needs to be in potentially dangerous situations, such as working at height. The drone can collect data for you, with your personnel safely on the ground and away from hazardous areas.

- Cost reduction: Drones save money in many ways - from requiring less manpower to eliminating the need to erect scaffolding.

- Downtime: Keep operations and resources open and running during critical inspections. Reducing or even eliminating downtime can save huge amounts of money.

- Increased efficiency: drone inspections greatly increase the time it takes to inspect one or more assets.

- More inspections: In general, a drone inspection provides a cheaper and more efficient inspection solution, allowing for more frequent checks. This in turn means that any problem can be identified and resolved much more quickly.

- Better data: Drones collect quality data, which can be archived to create a detailed record of the life cycle of an asset. Drones can conduct automated and repeatable missions, ensuring data is consistent every time, especially vital for regular and comparative checks.

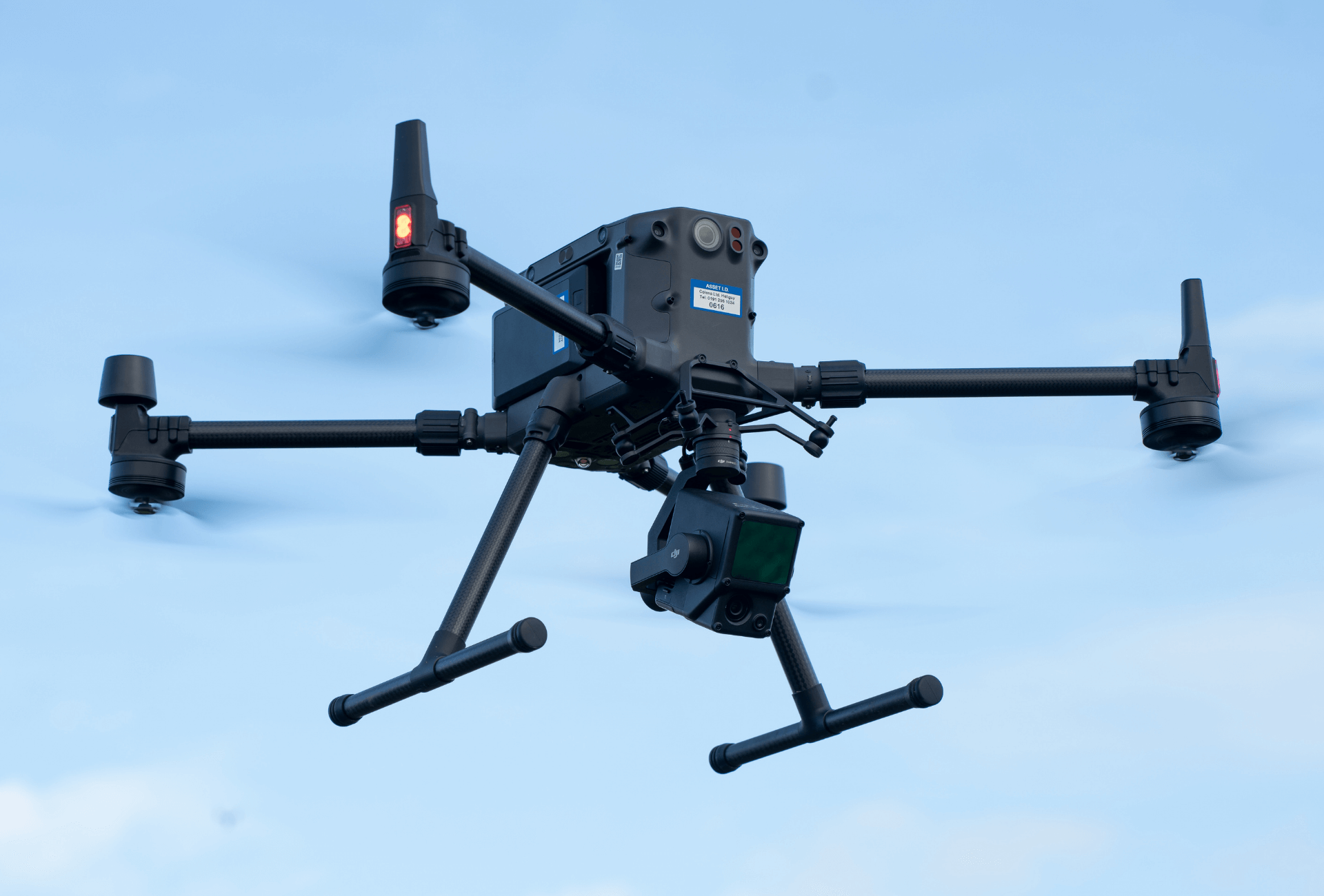

- Versatility: Some drones, such as the M300 RTK, can be integrated with a range of different payloads to collect a variety of data, such as thermal, zoom and LiDAR. In the case of the M300 RTK and H20T payload, use the camera's four-sensor sensor array of thermal range finder, wide angle, zoom and laser, to maximize data collection and increase mission efficiency.

“In offshore installations, a point of continued interest is that of the gas torch / vent structure. Any type of close inspection of the boom or tip requires a rope access crew and, as a result, a platform level shutdown is put in place for the safety of the crew, stopping any further oil / gas production until it is completed . Alternatively, the team must wait for an opportunity to initiate an arrest before they can conduct the inspection. This can cost millions a day. But using a drone, an inspection can be carried out at any time, as an experienced pilot can safely fly over these facilities during full operation, knowing how to keep away from any fire or gas exposure, meaning the platform can continue. its production and not lose potential millions. "

Tim Harris, RUAS

Why do this? ...

- Dangerous

- Takes time

- Labour intensive

- Various levels of data accuracy, for both single and repeatable inspections

… Or this? ...

- Very expensive

- Noisy

- High costs = less frequent inspections

- Fast speeds / difficult camera angles = lost data

… When can you do this?

- Cheap

- Fast, efficient and safe

- Range of cameras for diversified data collection

- Autonomous flights = repeatable / accurate data collection

“With an inspection time per wind turbine of 15-30 minutes, the drones reduce working hours and downtime for maintenance checks by more than 75%. An energy company achieved a 95% ROI for drone inspections of wind farms thanks to cost savings and increased efficiency. "

The Case For Drones In Energy - a White Paper by Measure

“We see drones as generic data collection tools that drive information gathering without increasing operational exposure. We can keep people out of trouble and we don't have to put them in potentially dangerous situations to get the data we need. "

Adam Serblowski - Robotics Theme Lead, Shell

TYPES OF INSPECTION WITH DRONE

Collect a variety of data.

Accurate information. Insights.

Drones are a versatile solution, capable of using a variety of different cameras to capture a wide range of data for inspection purposes.

This allows for insights for more informed decision making and a more efficient response.

Types of drone inspection include:

Visual inspections with drone

A visual survey will make up the vast majority of drone inspection missions.

This type of investigation is very similar to what it sounds like: a thorough visual inspection of every part of an asset, be it a power line, a wind turbine or a building.

In this case, the drone's camera becomes the operator's eyes and images can be collected during a short drone flight and then reviewed in detail later.

Using a drone for this type of inspection eliminates the need to erect scaffolding or shut down a facility.

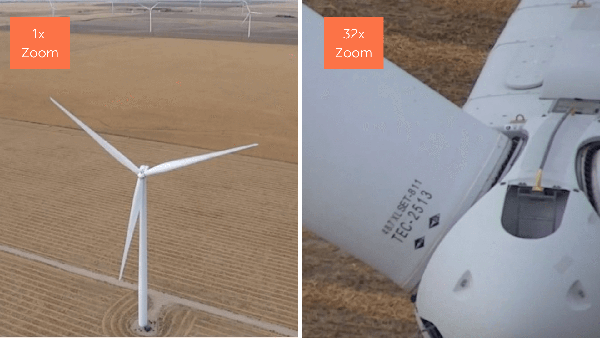

Investigations with drone with zoom camera

A key part of a visual survey is to use a zoom camera to locate an area of interest. This has numerous advantages.

Using a zoom camera offers a higher level of detail, allowing inspectors to find small flaws, rust or missing parts, all without having to interrupt the operation.

The use of the zoom helps to acquire this data from afar, avoiding dangerous and laborious working hours related to climbing and keeping personnel away from potentially dangerous situations.

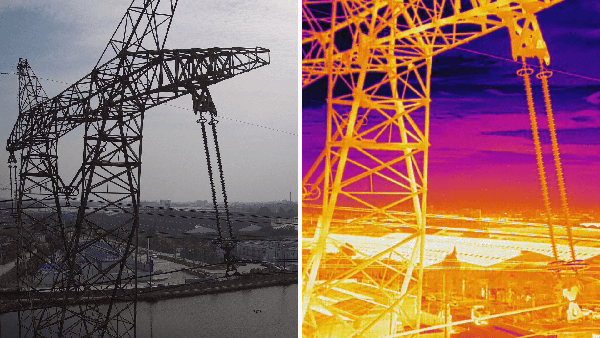

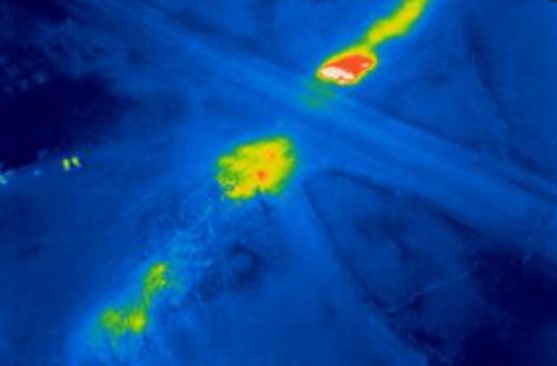

Thermal inspections with drones

Thermal imaging from drones is powerful, especially for service and building inspections.

Operators are able to locate missing or damaged installations, water under roof membranes, external electrical problems, broken windows and many other problems.

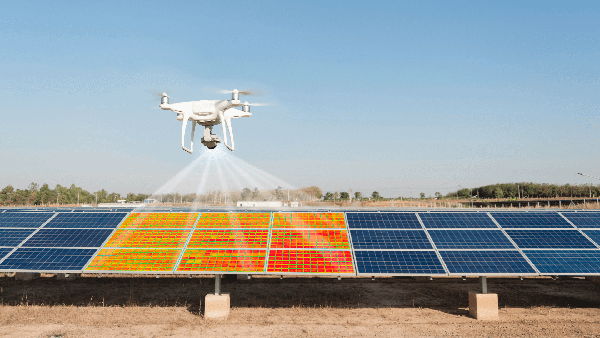

In the case of solar panel inspections, drones with thermal cameras can identify manufacturing defects, cracks, faulty interconnectors and temporary shading.

One of the most powerful aspects of a thermal imager is that it can detect and highlight problems that may not be detected during a visual inspection.

This data helps operators make informed and timely decisions to achieve efficient resolutions.

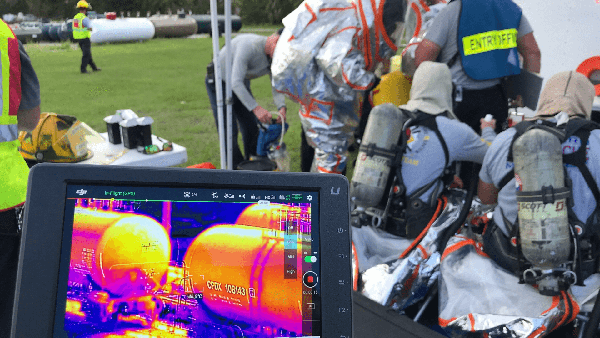

Investigations of hazardous materials with drones

HazMat inspection is a risky business - it involves volatile and toxic materials.

Drones are helping with this type of inspection by reducing the need for humans to access the site.

Drones can carry specialized detectors to help with HazMat inspections, identifying things like steam, chemicals, and radiation.

This reduces the number of interventions that personnel have to perform, in turn improving the safety and speed of the inspection.

Drones are capable of broadcasting footage or gathering information that can be shared remotely to aid in decision making while improving safety.

Photogrammetry and mapping with drones

Photogrammetry is a popular drone detection technique and can be a useful application for inspections.

Photogrammetry is the process of acquiring high-resolution images and merging these images into specialized software to create accurate real-world digital twins.

This technique can be used to build detailed and georeferenced 2D orthomosaics and 3D models.

These offer highly accessible images of an inspection area and can be used to perform measurements, such as stock calculations. This data can be quickly shared with team members and stakeholders.

For these reasons, photogrammetry has become a crucial tool for inspections, capturing aerial views, tracking changes, and tracking progress on a construction site, for example.

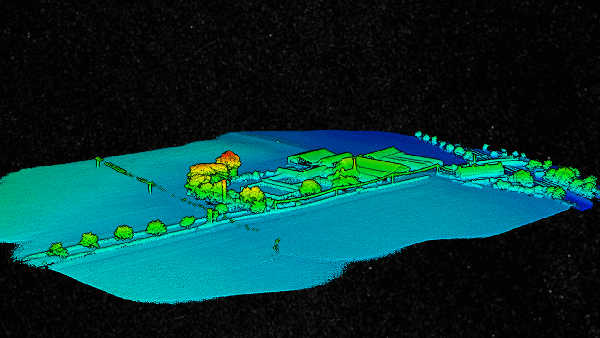

LiDAR inspections with drones

Drone LiDAR (Light Detection and Ranging) is a useful tool in the inspection toolbox.

LiDAR sends out thousands of pulses of light every second to help build accurate 3D models of the world.

This can be useful for a variety of inspection missions. Take power lines, for example. LiDAR point clouds can be used to provide accurate data on the location and height of everything on the map and can be used to measure the distance between trees and power lines.

LiDAR is extremely powerful as it can be used at night and is particularly effective in areas with dense vegetation, as the LiDAR pulses are able to penetrate the spaces between leaves and branches to reach ground level.

Since LiDAR emits thousands of pulses, it can be used to create robust datasets, helping to collect smaller objects on a dataset, such as overhead cables.

INSPECTION WITH DRONE FOR INDUSTRIAL SECTOR

How drones are benefiting the business world.

Commercial uses for inspection drones

The benefits of drone inspections are clear, but how do UAVs help specific sectors?

The following section explores the use cases of drone inspection in the business sector and the types of inspection they are conducting.

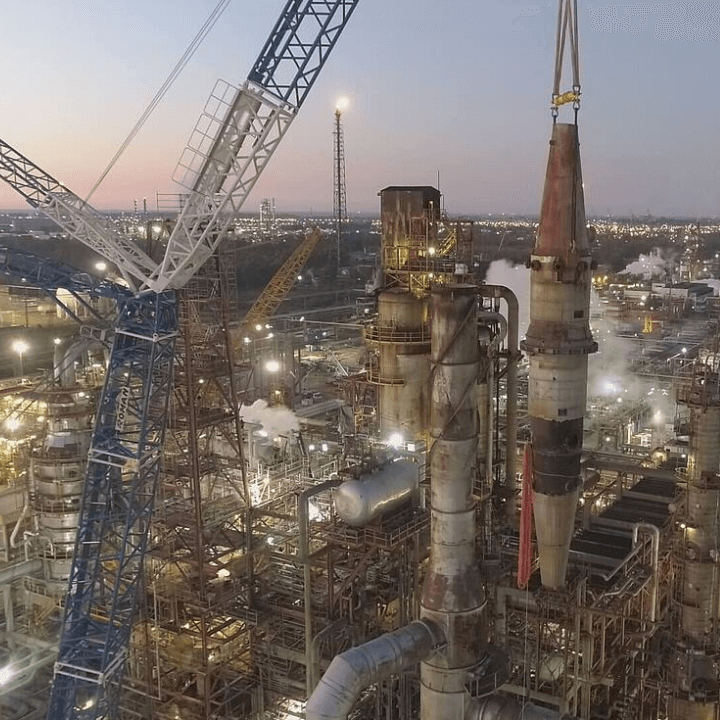

Drone inspections of oil and gas

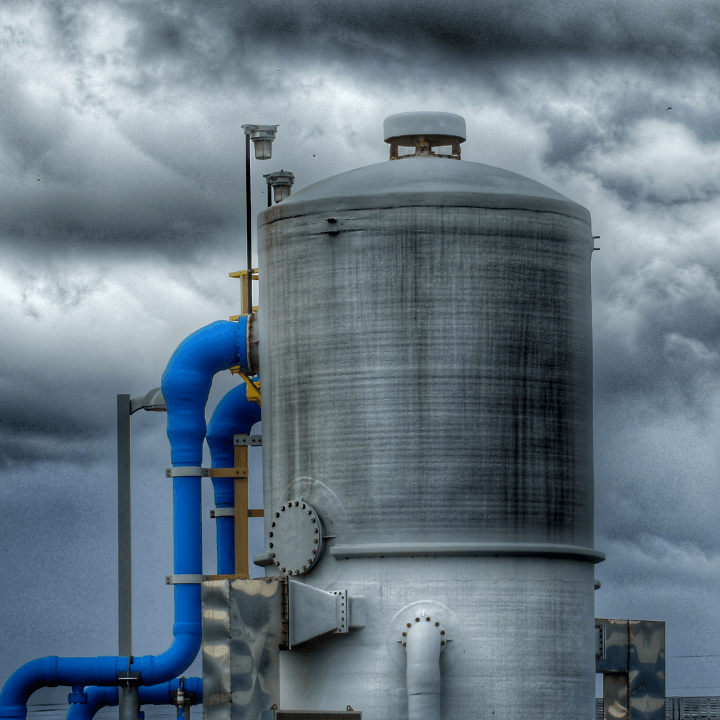

Drones help oil and gas professionals inspect and manage assets, such as refineries, storage tanks, offshore platforms and chimneys / chimneys, with minimal downtime and without compromising personnel safety.

Unmanned aircraft can be used to conduct inspections of refinery infrastructure to help identify failures or weaknesses. Before drones, helicopters would be needed to examine light signaling systems or the installation of scaffolding to allow personnel to inspect tall structures - both expensive, while the latter is also dangerous.

Drones can also be employed for pipeline integrity management. They can quickly cover large stretches of pipeline - especially useful when flying over complex, undulating terrain - helping to identify leaks or anomalies.

Drones can prevent downtime, reduce routine maintenance time, and perform inspections without having to stop operations. This is a big plus, as every second of inactivity is a loss of revenue.

Drones can help:

- Evaluate the functioning of the refinery torches;

- Evaluate steam systems;

- Identify weaknesses in structures;

- Point failures in the flanges;

- Reveal deformations.

Drones for energy inspection

Drones can be used throughout the energy sector. Below, we focus on how drones are helping inspect power lines, wind turbines, and solar panels.

Inspection of the drone's power line

Drones offer an effective solution to inspect and manage power lines, with greater speed, efficiency and safety, all while reducing working hours and costs.

Performing an automated drone inspection can save 30 to 50% of costs and time compared to alternative methods.

After all, traditional methods are expensive, laborious and dangerous. Using a helicopter is expensive, noisy, and complex, while manual methods can be dangerous, slow, and hindered by difficult terrain.

Drones change all of that. And they are particularly well suited for power line inspection as they help cover large areas quickly and are an ideal tool for repeat inspections; typical of the powerline inspection industry.

Using a drone, powerline inspectors can:

- Evaluate the conditions of all components of a power line without workers going up to altitude;

- Cover large areas faster - by increasing the number of power lines inspected - and reach places that are difficult to access;

- Inspections are conducted from a safe distance, with drone cameras such as zoom, thermal imaging, LiDAR and 4K providing key insights, all while staff keep their boots on the ground;

- Real-time data for informed and rapid decision-making and insights;

- Easily automate missions - ideal for efficiency, conducting repeatable flights and collecting year-over-year comparison data more reliable;

- High resolution visual inspections compared to ramp inspections; The towers remain functional during the inspection.

Use of Drones in the search for water leaks

Over the years, water pipes can have problems with leaks, often these are small breaks, which lead to a very slight and difficult to locate water loss, this involves not only a waste of one of the most important elements in the life, but in some situations they can also cause environmental damage, eroding or changing the environment.

The use of drones in this can help us not a little, in fact in recent years, some specialists in the sector are testing and bringing home excellent results with aerial surveys, with the use of this type of means, which allow to have an overview from above, using the different Payloads, such as multispectral or thermal chambers, in the first case by exploiting the multispectral values given by the chamber, data that are georeferenced, after the data collection, it will be necessary to carry out an analysis to confirm the presence of an excess of water in certain points. While the use of thermal chambers, exploits the sudden changes in temperature that exist in the fluids that pass in the pipes, when they have a temperature different from that of the ground they can be identified even if they pass through underground systems, in the same way the localization of leaks can also take place, also in this case, by exploiting the georeferenced data it is possible to have a complete and detailed analysis of the territory.

With this technique there are several advantages, among which; Rapidity of intervention, being able to cover large areas quickly and without too many movements, in some places it is often difficult to intervene due to the state of the soil or vegetation. but much higher costs, but the most important thing is the high definition data with the various sensors that can be analyzed.

The uses are the most varied, we can carry out periodic checks in dams, using not only drones with purely visual cameras, but also using drones with thermal or Multispectral, analysis of land water pipes, in search of leaks. Control of sewer pipes, control of waste for agricultural use.

This is why DJI collaborates with industry bodies by providing drones applicable to this use, offering the possibility of exploiting the camera of the DJI Phantom 4 RTK Multispectral with attached D-rtk2 gps station, which allows to have an accurate precision of all the survey performed. While to take advantage of the thermal dji offers the Dji Matrice 300 + H20T or the brand new M30T.

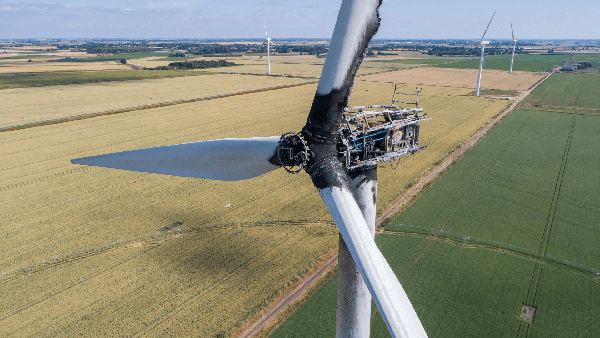

Inspection of the wind turbine with drone

Drone inspection can provide a visual and / or thermographic image of the state of the components of a wind turbine.

Using a drone to inspect wind turbines has multiple benefits, including a safe working environment, reduced downtime, high quality images and video, access to otherwise inaccessible areas, and dynamic detection. It is also more cost-effective and provides more accurate data than using helicopters for the same task.

The image above shows how a drone with a zoom camera can be used to locate all aspects of the turbine, so close that you can even see the serial number. This capability allows inspectors to quickly identify any defects from afar.

Meanwhile, thermal cameras can be used to check for structural problems and weaknesses in the blade. The blade surface temperature profile, for example, indicates potential defects. Therefore, thermal images are useful for discovering hidden defects and faults.

Inspection of solar panels with drone

One statistic says it all: Drones can collect solar panel data more than manual methods.

Drones with thermal cameras can perform a complete solar park operation in hours, compared to days using manual methods, increasing the quantity and quality of data and reducing costs.

In fact, a white paper from Measure states that a drone inspection of a solar park costs up to 46% less than a manual inspection.

A thermal imaging camera can help identify manufacturing defects, cracks, faulty interconnectors, faulty bypass diodes, and temporary shading.

Drones can also be used to collect RGB data, along with thermal images, to help with quantitative and qualitative analysis, both of which are essential for understanding defects on solar panels.

“Drone inspections in the energy sector can provide a higher level of detail - missing pins, rust, damaged insulators - than typical ground or helicopter patrols, while also avoiding the dangerous man hours involved in climbing. The cost of equipment, training, software, and support for an in-house drone program pays for itself 5 times more with just 50 miles of power lines inspected, plus an inspection of a substation. "

The Case For Drones In Energy - a White Paper by Measure

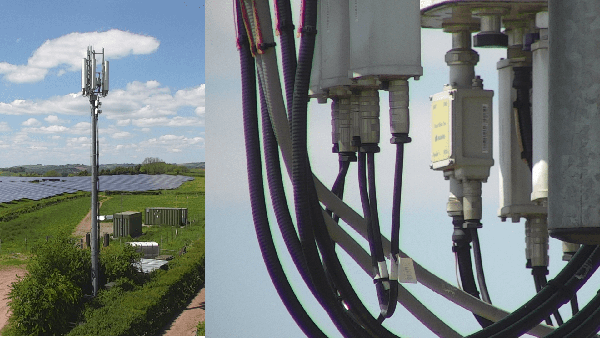

Inspections of utilities and infrastructures

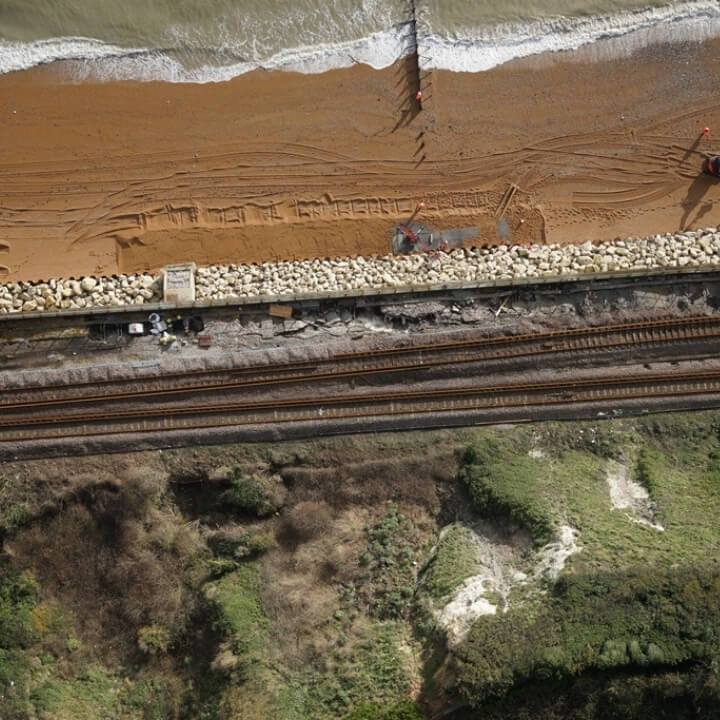

Utilities and infrastructure is a broad term, but it includes resources such as roads, bridges, telecommunication towers, and railways, among other things.

Drones are used in this industry to perform regular maintenance checks or following natural disasters - such as hurricanes or floods - where the condition of the property is not known but may have suffered damage.

As with other industries, one of the main benefits of using drones for public service and infrastructure inspections is the ability to acquire quality data quickly, safely and relatively cheaply. For example, personnel don't need to climb a telecommunication tower, but the drone can.

When it comes to bridge inspections, there is no need to use heavy machinery, as drones can collect the required data in one flight or series of flights and can perform follow-up inspections more regularly due to the ease and cost-effectiveness of the their use. These flights can also be automated.

Drones can also be used for project updates. Balfour Beatty used drones on a major development of the Smart Motorway, regularly flying the 13.6-mile stretch to track progress and spot errors. Imagine how much more difficult and time-consuming it would have been without a drone.

Drones can inspect:

- Service towers;

- Bridges;

- Roads;

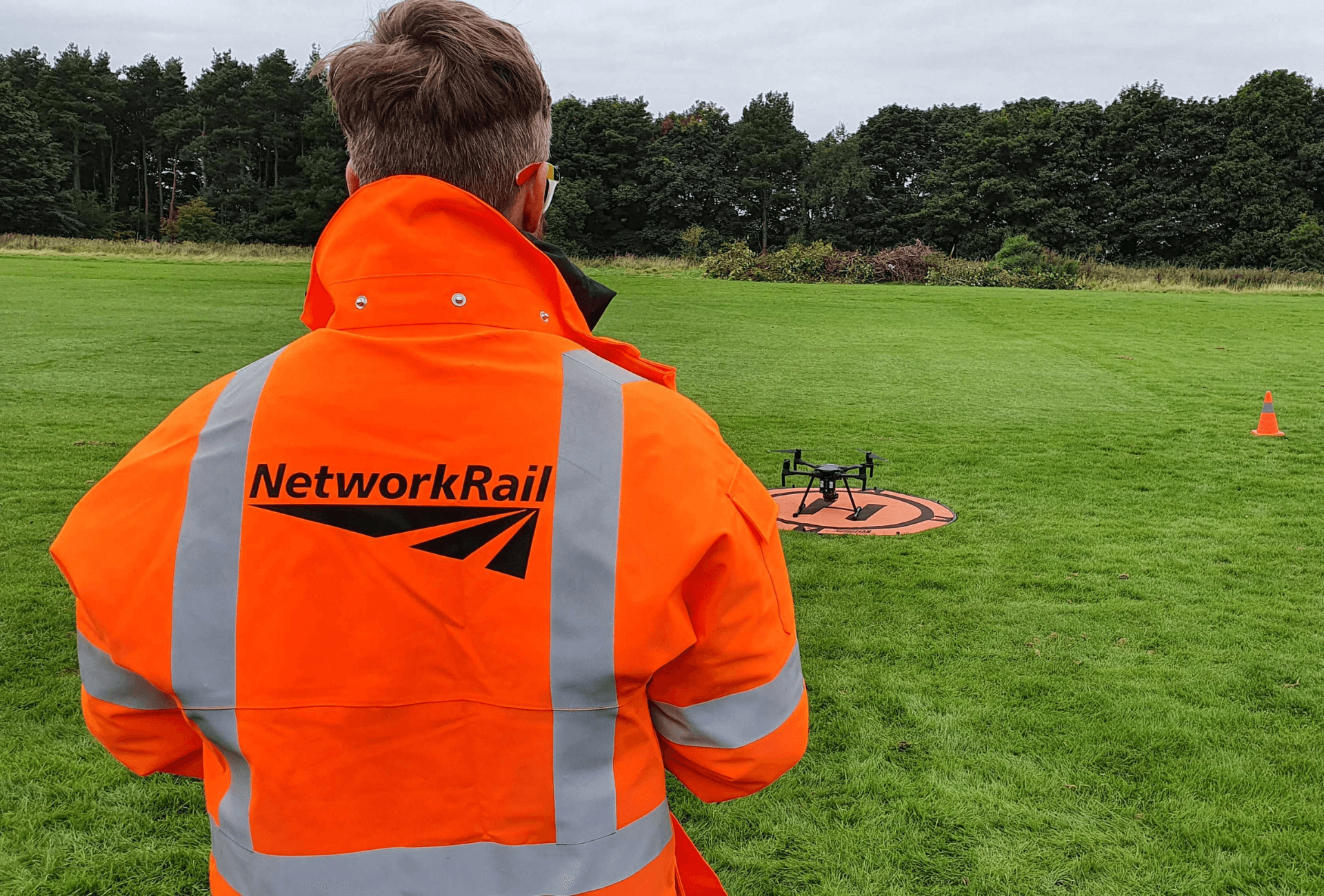

- Railway lines.

“Drones are a cost-effective solution for close-up inspections of difficult-to-access structures. Carrying out airborne inspections means we can keep the railroad open and our people safe: the trains can keep running, and since we don't have to send engineers to the tracks, it improves safety. "

Network Rail

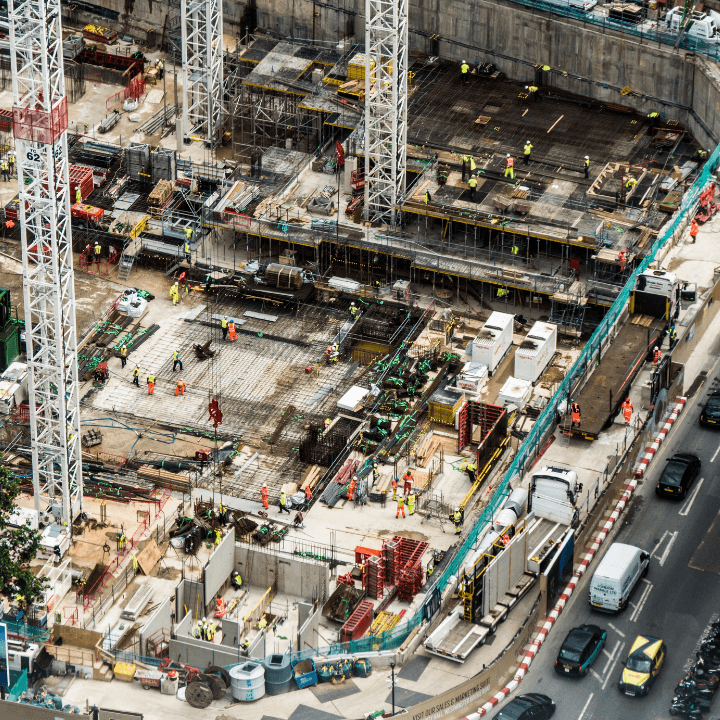

Building inspections with drones

The construction industry is the fastest growing user of commercial drones and inspection plays a significant role.

Deploying drones for construction can save hundreds of thousands of pounds over the life cycle of a project and can be much more efficient than traditional methods, taking hours to collect data instead of days in some cases.

Drones can be used in the construction industry to monitor progress on site, check for errors, measure inventory and compare actual construction against design plans.

As a result of drone inspections, companies are able to build 2D orthomosaic maps or 3D models for highly detailed and accurate visual representations of the design. These digital twins can be shared quickly and easily with staff and stakeholders to improve communication and decision making.

Drones can also be employed to inspect the job site for any safety or maintenance issues, such as a damaged section of the perimeter fence or using a thermal imaging camera to detect an overheated tank, for example.

As a result, drones help construction companies meet deadlines, reduce costs, improve communication, and protect workers.

“Thanks to drones and associated software, data can be collected from a site in half an hour, compared to three days using traditional handheld methods. Drones enable companies to create highly accurate point clouds and maps, uncover costly jobs - site errors and predict planning delays, saving up to tens of thousands of pounds a week. '

Richard Clement, Komatsu

Relief with agricultural drone

Drones have quickly emerged as a vital tool for agriculture, replacing the ancient method of farmers walking their fields manually to monitor and inspect their crops.

Thanks to drones and their sophisticated array of sensors, farmers are able to increase crop production, monitor and inspect crop growth, create a richer picture of their fields, improve agricultural efficiency and maximize results.

For example, farmers can build 3D models of their land to better understand irrigation conditions or use a drone to provide regular updates on crop conditions in remote locations on a large farm.

Drones are able to obtain this information much faster than walking in the field and, compared to manned aviation, are a much more accessible and cost-effective method. This data can also be collected over time, allowing farmers to compare crop patterns across seasons or years.

Drones provide information in real time and are not evasive to crops.

Resources for inspection include:

- Collected;

- Irrigation;

- Ground conditions;

- Soil health;

- Livestock.

“Efficient weed control in an agricultural operation is critical. Knowing when and where to apply the herbicide can provide significant savings, not only in preventing crop damage, but also in minimizing the amount of product that is purchased and applied. Remote sensing technology can help growers evaluate the effectiveness of treatments, identify problem areas and implement necessary corrective actions ”.

MicaSense and Dynamic Wings

Public safety drone programs

Public safety officials are increasingly using drones for inspection purposes.

UAVs are powerful during a live crash, thanks to their ability to deliver real-time footage and vital situational awareness, helping to model a more effective response and keep crews out of harm's way.

The partial collapse of the dam wall at Whaley Bridge in 2019 proved this. Derbyshire police have deployed a DJI drone, with a zoom camera, to inspect the situation and monitor the extent of the damage. Without the drone, someone would have had to approach the damage, climb a rope along the dam to get a look and risk their own life.

As the image shows, the police also used the drone to check where the bags of aggregate from RAF Chinooks were placed to secure the damaged section and look for any violations, providing instant, real-time and close-up information thanks to the zoom.

Officials can also employ drones to inspect a crime scene or conduct an accident scene investigation.

Public safety drone inspections include:

- Collection of visual data of ongoing incidents, such as fires;

- Vital situational awareness to help distribute resources in the safest and most efficient way;

- Distribution after an event, such as inspecting areas destroyed by fires, for example;

- Accident reconstruction;

- Inspection of public spaces such as stadiums or festival grounds for safety concerns or pre-event planning.

“Using a drone for accident scene investigation and accident reconstruction is about a hundred times more detailed than we could do with people taking measurements manually. And it means there is much less time to close the road and block traffic. "

Chief Deputy Jeff Lower of the Tazewell County, Illinois Sheriff's Office

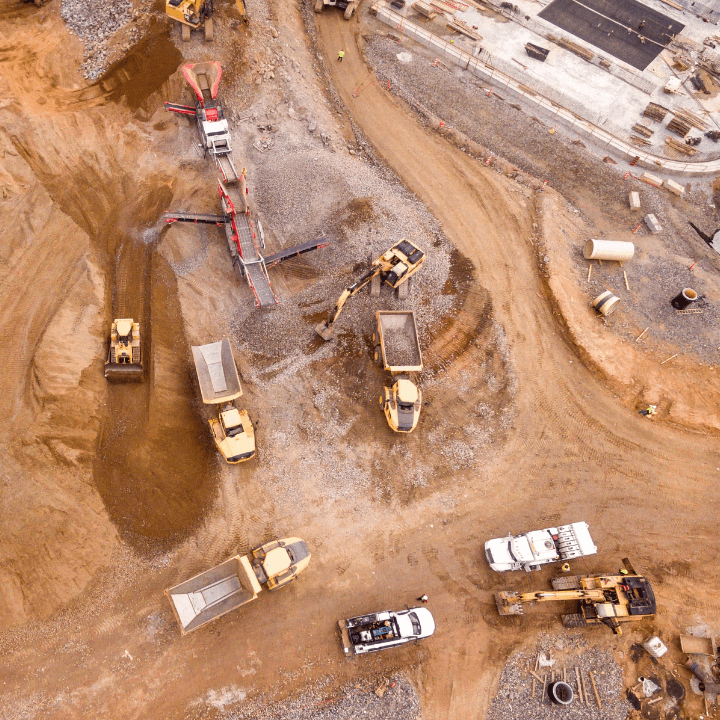

Inspections with mining drones

The mining industry is one of the fastest to adopt drone technology and it's easy to see why.

Mines are dangerous and hostile environments, so drones allow for fast and accurate data collection, keeping employees safe.

Drones also allow access to the inaccessible, which in turn helps stimulate better planning and decision making.

Drone inspections can be used throughout the life cycle of a mining operation, from mapping areas of interest and potential explosion sites during the exploration phase, to documentation of equipment during construction and details of the final site at closing.

But their most common and practical use is during the operational phase. Drone inspections provide an overhead view of the site, showing overall progress, evaluating transport routes, highlighting any stability risks or illegal mining, and monitoring the management of pits and landfills.

They can also be used to inspect on-site assets, providing real-time insights into the process. These inspection resources include:

- Open Stope : Supports backfilling operations by exploring restricted areas such as excavated open stops. Understand the conditions of the terrain without putting personnel at risk.

- Drop Raise : Identify a clog by flying down a dusty, wet and rocky rise in an underground mine.

- Stock Feeder - Assess integrity and schedule maintenance by flying through the storage hole and collecting images.

- Conveyor belt : There is no need to disturb the operation and stop the excavation in progress; use the drone to assess the integrity of the conveyor belts.

- Blast Areas - Produces affordable and accessible 3D reconstructions and surface models for areas to blast or drill through, helping to better plan resources.

“We use DJI drones for many investigation and inspection jobs, helping to improve decision making and streamline inspections. Drones help the mining industry for a variety of reasons, including increased safety, removing employees from hazardous areas, and increasing cost savings. We use drones for a variety of operations, including reality modeling, asset management, and drill / blast analysis. For us, UAVs are another tool in the toolbox ”.

Andrew Carey, of Rio Tinto Kennecott Utah Copper

Chemical inspections with drones

Drone inspections in the chemical industry have a major advantage: they reduce the need for humans to be exposed to potentially harmful materials.

This is crucial, because inspection within the chemical industry is an important task. Any leakage caused by an improperly maintained storage container could have serious consequences. For example, spilling chemicals into a stream or into the ground could cause serious health problems for people in the surrounding area.

Thus, drones can be used to quickly and safely inspect the integrity of a chemical company's assets. And because a drone reduces the need for personnel to approach tanks or containers, there is less need to build time-consuming and costly scaffolding.

Drones can be used to inspect the following assets:

- Rack for pipes;

- Cables;

- Fermentation tanks;

- Storage tanks;

- Suction ducts;

- Heat exchangers;

- Silos and storage containers.

“A number of advantages are associated with the use of drones: greater safety margins; risk reduction; better efficiency: get more work done in less time, with fewer people and save money; and deliver high-quality data faster, typically within minutes of completion. In one case, we used a drone to inspect the fin tubes in the convection section to determine whether or not a carbon dioxide explosion was needed to clean them and restore their efficiency. The drone data helped determine that we could have forgo cleaning in this outage - a very significant savings. "

Larry Barnard, El Segundo Refinery

Inspections with drones in the insurance sector

A drone is a useful tool for insurance claims, particularly after a natural disaster or event such as a fire.

Drones have the advantage of being able to safely access damaged or dangerous areas and collect unique aerial views of a disaster area.

High-resolution visual images can be quickly collected by drones and easily shared with insurance companies, providing a true and clear record of damage to help validate an insurance claim.

For example, the 2018 Camp Fire was the deadliest and most destructive fire in California's history and the most expensive natural disaster in the world for that year in terms of insured damage.

Following the incident, drone maps of entire neighborhoods were created, allowing homeowners to send images to insurance companies to process claims immediately, a process that traditionally could take days or weeks. Many have also used the images to access FEMA relief funds for families affected by the fires.

The same happened following Hurricane Irma, which hit Cape Verde. Extensive property damage meant that claims adjusters needed to inspect each facility and estimate the cost of repairs before insurance companies could begin helping island residents get back on their feet.

From the ground, it would take months. But by using drone maps to assess structural damage caused by the hurricane, insurance inspectors cut the process down to days, all while improving safety, data collection and response times for the claim process.

In addition to disaster areas, drones can be used to inspect the following for insurance claims:

- Road accident scenes;

- Damage to farms / crops;

- Buildings and related infrastructure on an insured site.

“After the wildfire, we used drones to take 10,000 photographs from below and stitched them together into an orthomosaic map so that the citizens who lived there and couldn't return could take a look at that map until address them and could see what had happened to their property without entering a dangerous area. We learned that mapping was really important as part of an integrated emergency management strategy ”.

Commander Tom Madigan, Alameda County Sheriff's Office

Scientific inspections with drones

Drones are deployed by academics and professionals to conduct science inspection missions.

Volcano Inspections : Drones are changing the way scientists can sample and detect previously inaccessible volcanic plumes, acquire limited information through ground-based techniques, and conduct short-range gas checks. Using drones for this type of study helps protect local communities by obtaining key information on volcanic activity and makes inspections safer and more accessible. .

Inspection of radiation levels in Chernobyl : Drones were used to complete comprehensive inspections of the Chernobyl Red Forest, one of the most radioactive places on Earth. The drones helped provide up-to-date information on the sites with the greatest contamination and also revealed previously undetected radiation hotspots. The use of drones allowed scientists to investigate dangerous places from a safe distance. The UAVs also helped the team quickly cover large areas. Read the full case study here.

“Drones are changing the way we study and inspect volcanoes and have enormous potential for monitoring volcanic hazards. Many areas of the volcano are too dangerous to walk, so we used drone technology to bring our instruments close enough to take direct measurements. "

Dr Emma Liu, University of Cambridge

INSPECTIONS WITH DRONE: CASE STUDIES

How drones are used in the real world for inspections.

30% efficiency savings using DJI M300 RTK

Valmont Industries has made significant savings in efficiency by using drone technology or, more specifically, by piloting the DJI M300 RTK with H20T camera.

The company has to inspect more than 2,000 inspection poles, which cover 12,000 square miles. Using the drone has the following advantages:

- Increased efficiency : The drone can inspect up to 12 poles per day, compared to four with a crew of cranes. The resistance of the M300 RTK also helps to increase the number of poles that can be inspected during a day.

- Comparable data : Using the AI SpotCheck function on the H20 series camera, the crew can repeatedly conduct the same flight. This allows them to compare apples to apples, to see if there have been any significant changes in the structure over the course of multiple years.

- Increased Zoom : The H20T has a 23x hybrid optical zoom and a maximum 200x zoom. This zoom increase allows the team to spot smaller defects, helping to check for missing items, such as nuts and bolts.

“Drones are changing the inspection industry. They make the inspection more efficient and faster. We have many poles to inspect, but we can do it in much less time with drones than with traditional methods ”.

Valmont Utilities Staff

Global oil giant Shell benefits from drone data

The Shell Deer Park team in the United States has been using drones on site since 2016 to inspect and maintain industrial equipment, reducing the need for dangerous and daunting climbs, improving safety and cutting inspection costs.

Flare tips and floating roof tanks are among the key assets requiring scheduled inspections; a process made easier, safer and more efficient with a drone. After all, their condition and activities are difficult to assess from the ground.

More recently, the team implemented the M300 RTK with H20 camera, with outstanding results, especially when inspecting structures and navigating steam pipe systems.

- 200x Optical Zoom : The team was able to get close-up views of each asset from a safe distance, without sacrificing image quality.

- Omnidirectional Obstacle Sensing : When inspecting pipe racks, for example, the M300 RTK can self-correct and fly between objects before descending to the correct altitude. The team no longer has to worry about the drone stopping after detecting an obstacle and putting the pilot in a difficult situation.

- Extended Flight Time : The M300 RTK can stay airborne for 45 minutes when flying the H20. This is particularly ideal for demanding missions and for obtaining as much data as possible during a single flight. The ability to hot swap the drone's TB60 batteries without interrupting the mission is also a great time saver.

- AI SpotCheck : Automate missions to collect repeatable data on each flight; particularly useful for periodic inspections of the same asset. It means there are no more conjectures; the team can get the same picture of the same tank every week, making it easier to compare problems and make smarter maintenance decisions.

- Health Management System : This system simplifies fleet maintenance and monitors the flight data of each aircraft over time. The team can now better understand their fleet performance and make decisions based on service data.

“Steam system leaks and other abnormal situations require an eye to the sky. Procedures are in place to ensure that the drone team is around when they occur. We will receive a phone call or it will be mentioned in the morning briefing. I will hear firsthand what the engineers need and we can quickly put together a mission plan, do risk assessments and have a drone in flight within 20-30 minutes and things can be assessed in real time. "

John McClain, Chief Drone Pilot at Shell Deer Park

Save time and money for the customer

Drone service provider, Terra Drone Europe (formerly Skeye BV), uses drones for offshore inspections, benefiting from increased safety and efficiency.

Working on behalf of a major oil company and deploying the DJI M200 drone with the Z30 zoom camera, Skeye BV achieved the following:

- Time Saver : Drone inspections took several weeks, but saved several months of laborious rope access inspections. After evaluating the drone images, the Rope Access teams were called in to repair the defects.

- Access to all areas : The M200 was used to inspect external features, while an alternative drone was used for inspections in confined spaces. This ensured that all areas were inspected, including areas that were difficult to access.

- No downtime : Terra Drone had to inspect stocks. The drone offered a safe inspection solution without affecting operations on the platform, providing a comprehensive inspection of the torch stacks while they were in operation.

“The M200 is the main element of the fleet after proving its worth in the last year of offshore operations. When equipped with the Z30 payload, the reliability and results are outstanding. It makes our surveys extremely safe as we can fly farther from structures and get better results than previous cameras without zoom capabilities. The data produced by these flights were significant and make the management and interpretation of the data extremely efficient and complete ”.

Patrick Rickerby, Terra Drone Europe

Rooftop inspection drones

This image shows the power of using a drone and zoom camera for roof inspection work.

Quayle Industries used the DJI M210 V2 with the Z30 to conduct the assessment: the top image shows the top view over the building, while the bottom photo is a crystal clear image of two of the fireplaces, as captured using the zoom.

This technique allowed the inspection to be completed without having to send team members to the roof, improving safety. This data was acquired with the boots firmly on the ground!

As a result, it was also a great time saver, as information was gathered much faster than manual methods. Imagine how much slower the process would be if a scaffold had to be erected, followed by someone having to climb to the top and take photographs manually, not to mention the dangerous and expensive!

This inspection method also didn't skimp on quality, with the Z30 collecting every detail of the two fireplaces, helping to guide decision making and remedies where needed.

“If you need an asset inspection, drones can take high definition photos that show the condition of the property. This is perfect for rooftops and other hard-to-access areas. For roof inspections, you will be able to see if there are any broken tiles, moss buildup, or other damage. And after the repair is done, an aerial inspection will show if the repair was done correctly. Using a drone eliminates the need for raised platforms or scaffolding, reducing costs, time and, above all, risks. "

Quinton Quayle, Quayle Industries

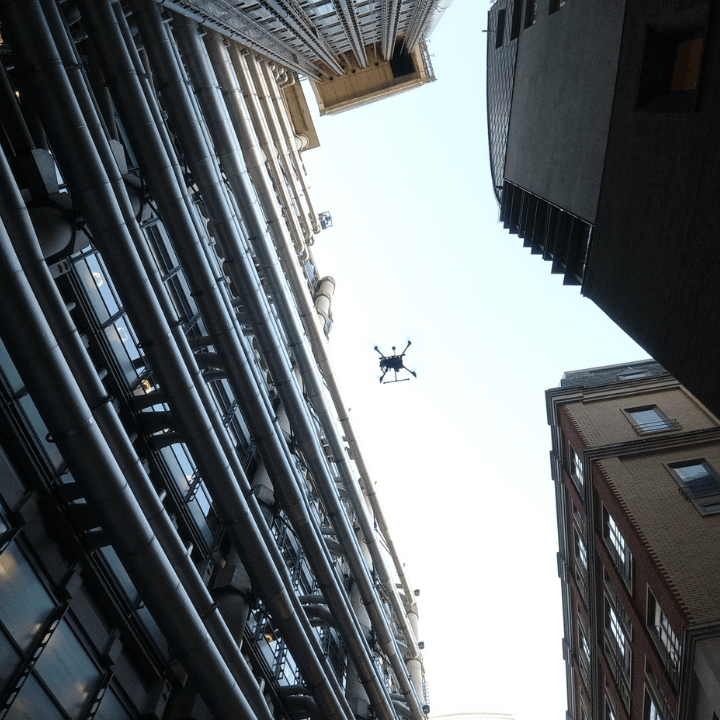

Inspection of the Lloyds Building in London

Digital services company, The Virtulab, completed a drone inspection of London's iconic Lloyd building, using a DJI M210 RTK and X7 camera.

The team obtained an operational security case for flying near the building within the City of London, the capital's main financial district.

The brief was to capture the details of the Lloyd's facade as part of a five-year project to assess and monitor the building's exterior fabric.

Using the drone has had numerous advantages:

- Greater safety and efficiency : The drone has replaced the need for rope access, saving time and improving safety.

- Non-invasive inspection : The Lloyds building is Grade I rated. The drone was able to keep itself away from the structure, preventing any bumps, scratches or damage that could be caused by alternative methods.

- Reusable Data : Using the drone was ideal for acquiring consistent data, eliminating the need to rappel outside the building and stopping at regular intervals to take pictures manually. Accurate drone data is a more reliable process for cross-referencing and validation throughout the project lifecycle.

“It is much easier with a drone to achieve the right workflow; not only is it quicker and safer, but it is also a more methodical and consistent way of capturing the data you need, which in turn is better for cross-referencing and validating. "

Mike Hibberd, The Virtulab

BEST DRONES FOR INSPECTIONS

Harness the power of the DJI ecosystem.

Different drones for a diverse data collection

DJI offers a vast ecosystem for drone inspections, allowing operators to acquire fast and reliable data.

The versatility of the aircraft available ensures that there is something for every mission, from the powerful and larger M300 RTK to the small, foldable and portable Mavic 2 Enterprise Advanced.

Some of the prominent solutions include:

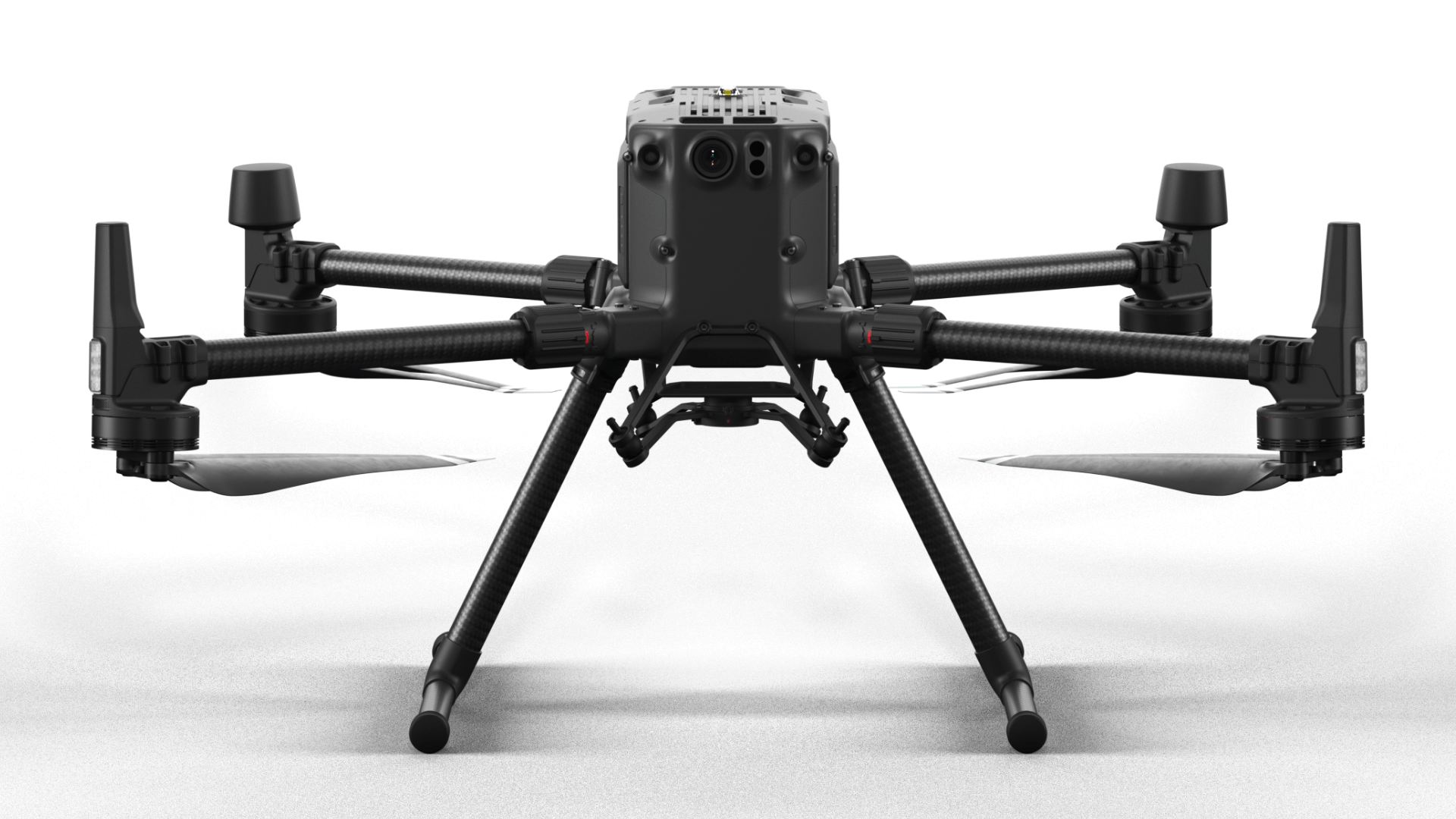

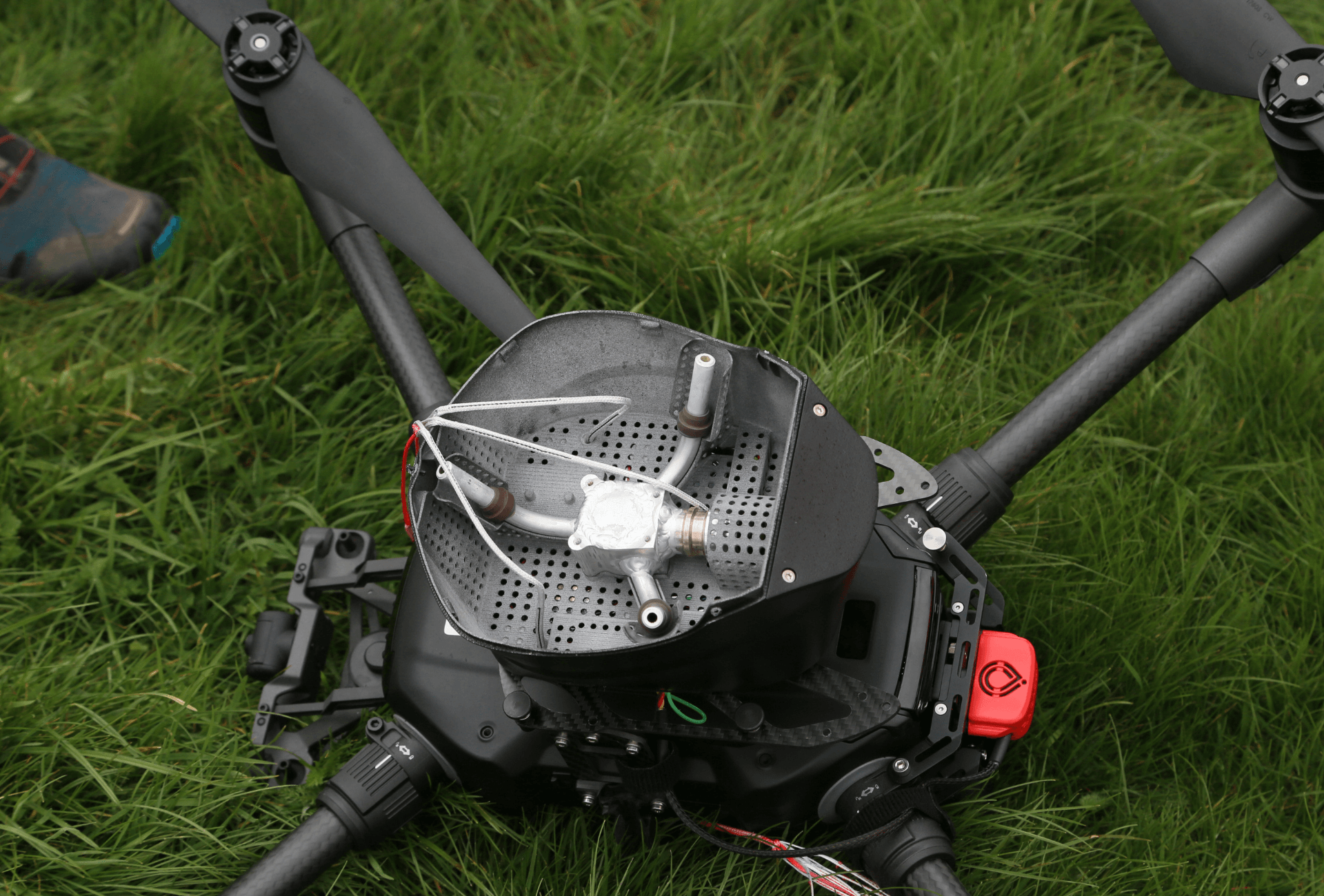

M300 RTK

DJI's most powerful commercial drone platform.

- Up to 55 minutes of flight;

- Carries up to three payloads simultaneously;

- Degree of protection IP45;

- Wide payload compatibility for inspections, such as H20T (including thermal, zoom, wide angle), L1 LiDAR sensor, P1 photogrammetry camera and third party payload;

- Plug in the CSM module to help detect small obstacles.

Mavic 2 EA

Compact drone for thermal, visual and zoom data.

- 640 x 512 px radiometric thermal sensor;

- 48 MP visual camera;

- 32x digital zoom and 16x thermal zoom;

RTK module available for CM-level positioning and increased flight stability, especially near power lines; - Create up to 240 waypoints for automated inspection;

- Complement it with extra accessories, such as a bright spotlight.

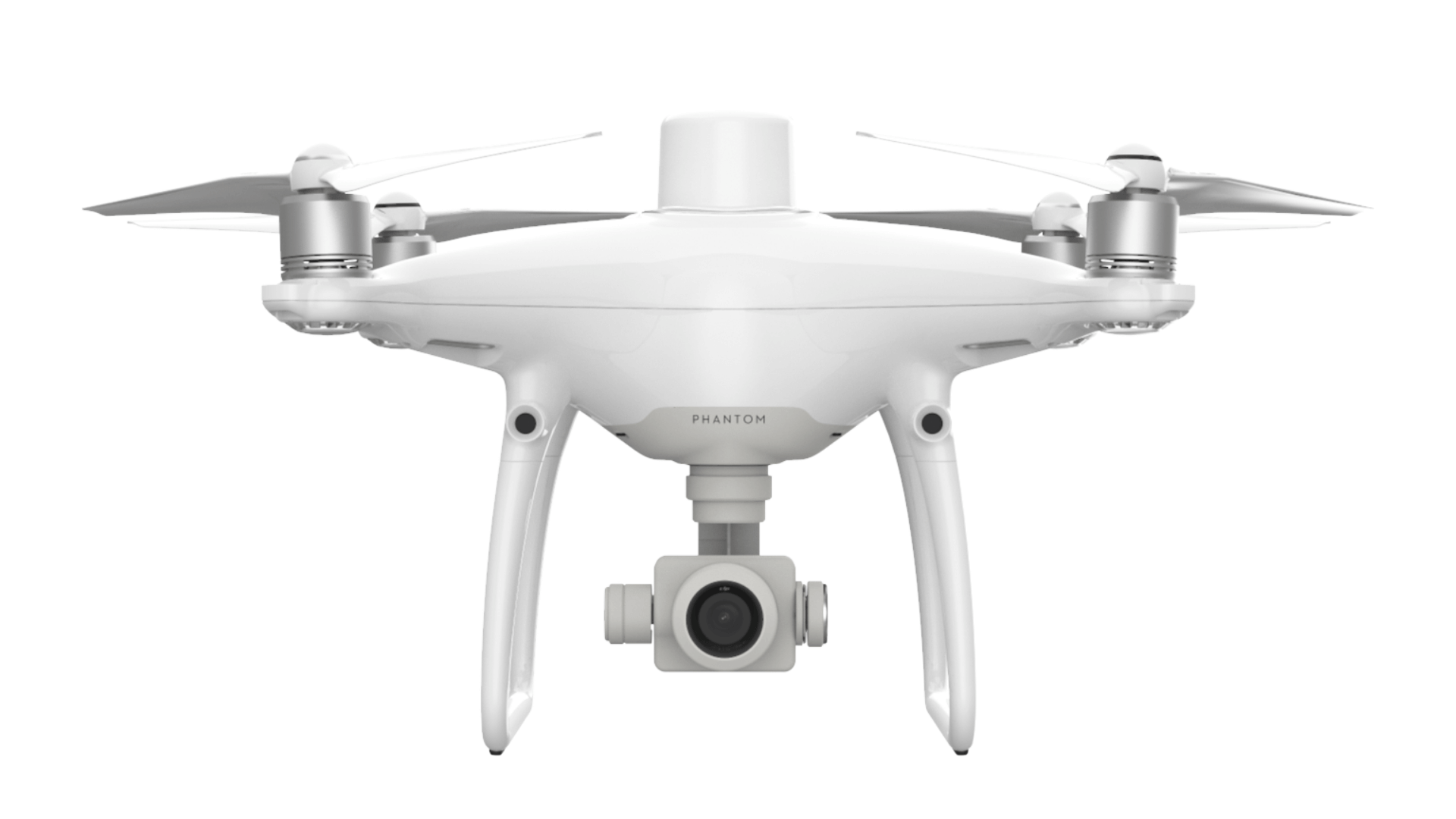

P4 Multispectral

Dedicated drone for agricultural inspections.

- An RGB camera and a multispectral camera array with five cameras covering the Blue, Green, Red, Red Edge and Near Infrared bands;

- All sensors are 2MP;

- Live RGB and NDVI feeds available from the drone;

- Integrated RTK for 1cm accuracy.

30T matrix

A versatile inspection solution.

-

IP55 rated for exceptional performance in harsh environments, including humid ones.

Operating temperatures from -20 ° C to 50 ° C.

Three propeller emergency landing, Health Management System, six-way obstacle avoidance sensors.

The OcuSync 3 Enterprise transmission

Lightweight integrated and foldable design (3.7kg take-off weight).

Phantom 4 RTK

Low-altitude mapping tool.

- 1 ”CMOS sensor; 20MP; mechanical shutter to avoid the blur effect of the shutter;

- Get 1cm + 1ppm RTK horizontal positioning accuracy and 1.5cm + 1ppm vertical RTK positioning accuracy;

- RTK module for CM-level real-time positioning data for absolute accuracy on image metadata. It also uses RTK for increased flight stability.

THE BEST DRONE ROOMS FOR INSPECTION

Variety of payloads for different missions.

Choose the payload for your inspection needs

The type of data you wish to collect during the drone inspection will determine which camera you will use.

Some drones, such as the DJI Mavic 2 Enterprise Advanced and the Phantom 4 RTK, have fixed cameras. But larger drones, such as the DJI M300 RTK Series and DJI Matrice 30T, can be integrated with a range of different cameras, allowing maximum flexibility for drone inspection missions.

The payloads available have a wide range of features, allowing operators to collect various data, such as thermal, zoom and LiDAR. Meanwhile, the bright Z15 spotlight is ideal for illuminating inspection areas, especially during low-light missions.

DJI H20 / H20T

Multi-sensor solution for a wide range of inspection missions.

- 20MP zoom camera, 23x hybrid optical zoom; Maximum zoom 200x;

- 12 MP wide-angle camera;

- 1200m laser rangefinder;

- H20T also has a 640 x 512 px radiometric thermal imaging camera;

- Intelligent and automated inspection features, such as AI SpotCheck;

IP44 classification; - Compatible with DJI M300 RTK.

DJI Zenmuse P1

High resolution photogrammetry.

- 45MP full frame CMOS sensor and 1 / 2000s shutter speed;

- Get 3cm horizontal accuracy and 5cm vertical accuracy with no ground control points;

- Highly efficient: coverage of the area of 3 km² during a single flight;

- Smart Oblique Acquisition;

- Use DJI Terra for data post-processing; TimeSync 2.0 microsecond synchronization

- Compatible with DJI M300 RTK.

DJI Zenmuse L1

Plug-and-play LiDAR sensor.

- Lidar module, 20MP RGB camera and high-precision IMU;

- High precision: vertical, 5 cm; Horizontal, 10 cm to 50 m;

- High Density Point Cloud: 240,000 points / s effective or further increase with up to three returns;

- View and measure point clouds in real time;

- Use DJI Terra for data post-processing;

- Compatible with DJI M300 RTK.

HOW 3DIGITAL CAN HELP YOU

HOW 3DIGITAL CAN HELP YOU

Full end-to-end support to grow your drone inspection business.

Your drone partner

A successful commercial drone program is based on a multifaceted approach. It's not just hardware; is developing a complete end-to-end workflow, with all components working effectively, together.

For this, you need a support pillar to help you build solid foundations, cover all the bases, and connect the dots.

This is where 3Digital can help you.

Our structure includes consultancy; software supply and support; pilot and sector specific training (through our partners); and DJI direct repairs, incident resolution and research and development to provide an integrated and comprehensive support network.

This approach allows us to enhance the drone programs of Italian companies.

Drone sales

- Free advice;

- National partner network;

- Service level agreements;

- Delivery in a few days;

- Financial options available;

Drone courses

- 3.000+ candidates trained by our partners;

- Courses approved by ENAC and DJI;

- Online training and distance theory exams;

- Closed courses and specific training in the sector;

- UTC DJI Academy courses;

Drone repair

- We rely on the DJI approved repair center, which offers accident support and repair management;

- Warranty repairs / replacements at no additional cost *;

- Firmware update and configuration support;

- Data analysis, customer support and resolution with the manufacturer;

WHAT TRAINING IS NEEDED FOR DRONE INSPECTIONS?

Get the qualifications you need.

Fly legally and safely

If you are planning to use a drone for inspection, it is important to understand the rules and regulations and have the necessary training.

Elite Consulting's team of training experts can help drone pilots obtain the necessary clearances and meet the correct training criteria to enable them to deploy unmanned aircraft for inspection work.

https://www.instagram.com/3digital.tech/

https://www.instagram.com/3digital.tech/