Power grid management - DJI ENTERPRISE

Main advantages in managing the electricity network

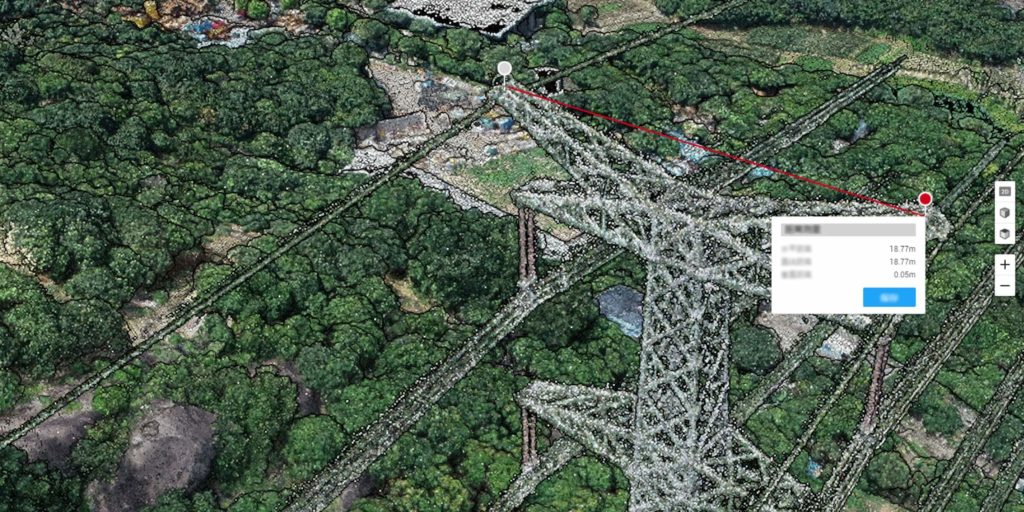

Vegetation management

Quickly map power line corridors, creating accurate 2D and 3D models that measure the distance between vegetation and power lines, helping to maintain a safe distance.

Resource integrity management

Conduct frequent inspections on demand to monitor the safety, reliability and integrity of the electrical network, improving efficiency and eliminating risks.

Detailed inspection

Capture standardized inspection data from automated drone inspections that accurately identify defects.

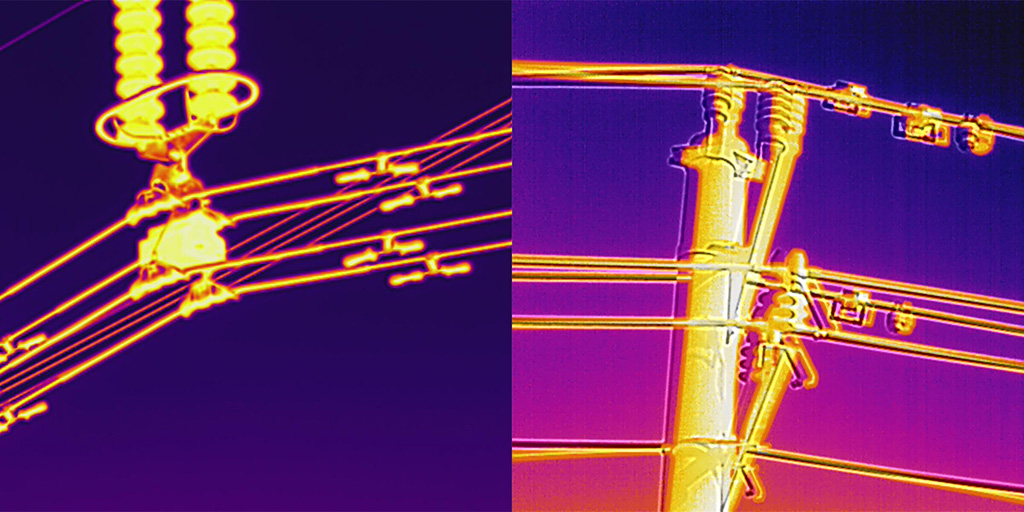

Thermal inspection

Get real-time temperature readings of assets using drones equipped with radiometric thermal sensors to immediately identify anomalies.

Fault inspection

Capture asset status from multiple angles using drones to reveal any faults or defects and fix them in a timely manner.

Night inspection

Conduct inspections in low light or at night using a drone equipped with a reflector.

Vegetation management

Traditional challenges in vegetation management

- Traditional methods using manned aircraft are expensive and require specific locations for safe take-offs and landings.

- In order to maintain a safe flight altitude, manned aircraft cannot closely follow the terrain, so it is difficult to accurately model corridors in mountainous areas.

- It can take several days to get the final model, from flight path planning, execution, data export to data processing.

How drones help manage vegetation

- Drones are portable and affordable and can be flexibly chosen in remote areas at a lower cost than manned aircraft.

- Drones can be used on complex terrain, with intelligent terrain following features to ensure flight safety without compromising data accuracy.

- 3D models can be created in real time for projects that have a tight deadline.

Resource integrity management

Traditional challenges in asset integrity management

- Power grids often span long distances, which can be difficult to access and manual inspections can be time-consuming.

- High resource hazards flaws may be overlooked when only observed from the ground.

How drones help manage asset integrity

- Drones can take off in minutes, covering large areas during each flight, providing useful information efficiently.

- Drones help identify asset integrity risks and inform response action by providing close-up data and comprehensive overviews.

Detailed inspection

Traditional challenges in detailed inspections

- Inspection personnel must examine and screen all components of a pylon, which is challenging for teams.

- Traditional inspections are unable to produce structured and standardized data that can be used to automatically detect defects.

Detailed drone inspection mode

- Automated flight routes can be set up to inspect increasing assets, creating detailed 3D point clouds without jeopardizing the safety of human operators.

- Drones are easy to use, allowing inspection teams to obtain high quality data with basic training, standardizing data output and streamlining processes.

- The inspection processes are closed-loop, ensuring data integrity.

Thermal inspection

Traditional challenges in thermal inspections

- Ground-based thermal inspection equipment cannot provide information on the condition of tall structures.

- Helicopter-based thermal inspections are too expensive to be conducted on a large scale, and the long installation time slows response efforts.

How drones conduct thermal inspection

- Drones can capture the asset from multiple angles and are easy to use so you don't miss out on crucial details.

- Drones are easy to use, take off in minutes, and aren't limited to stringent setup requirements, allowing for timely responses.

- Teams can get real-time, visual temperature readings across all parts of assets to quickly identify and fix problems.

Fault inspection

Traditional challenges in fault inspection

- Serious failures often require immediate repairs, manual inspections can cause delays in repairs that result in leaks.

- Inspection personnel must perform fault screening manually and may be limited by the accessibility of the resource and available tools.

How drones conduct fault inspection

- Drones provide an aerial perspective that captures critical information regardless of the environment, enabling teams to act quickly and minimizing losses.

- The drones are easy to use, take off in minutes, and aren't limited to stringent setup requirements, allowing teams to accurately pinpoint any faults.

Night inspection

Traditional challenges in night inspection

Inspections often cannot take place in poor visibility situations and personnel may be exposed to greater risks during night inspections.

How drones conduct night inspection

Drones equipped with spotlights and thermal sensors can identify hazards even in low light or at night.

https://www.instagram.com/3digital.tech/

https://www.instagram.com/3digital.tech/