SIMPLIFY3D® SOFTWARE

SIMPLIFY3D® SOFTWARE

Couldn't load pickup availability

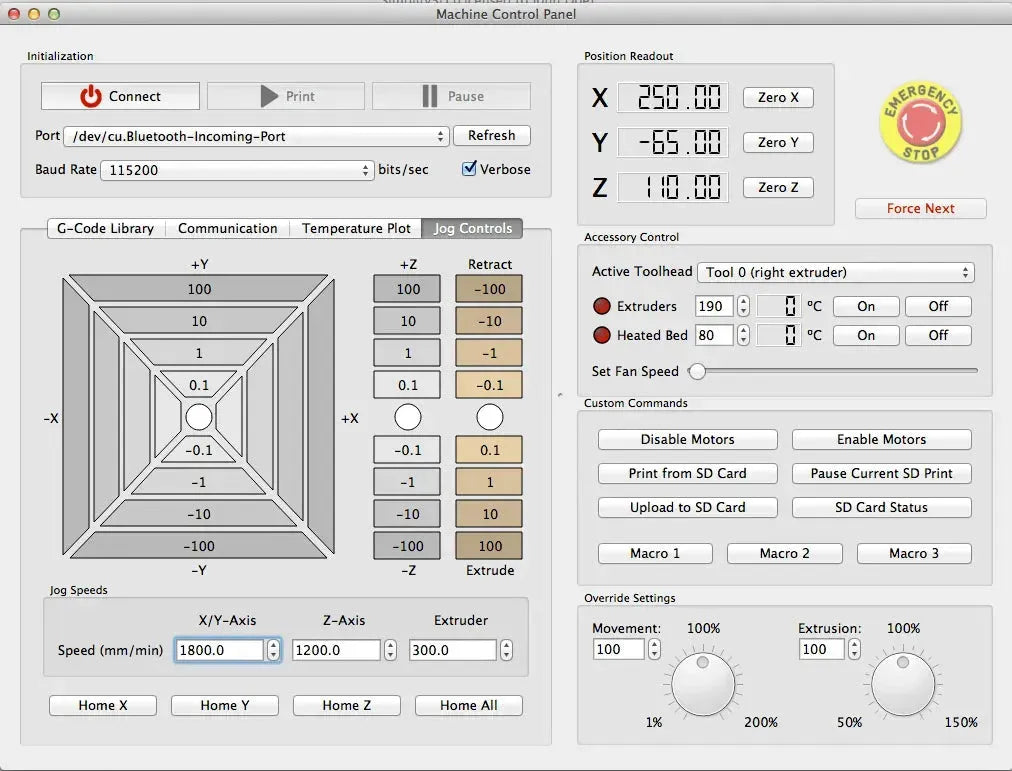

The Simplify3D slicer software suite contains everything you need to start making parts on your new 3D printer. Import your digital models/CAD data, select your pre-configured settings and generate your advanced G-Code instructions in seconds.

Main features:

- Smart and easy-to-use slicer software for your 3D printer

- Settings for the most common 3D printers and integrated materials

- Vary layer height, speed, temperature, and more within a 3D printing process.

- Innovative Support Structure - Additive Manufacturing with Soluble Support Filament

Note: This is a digital download. You will receive your license key by email after ordering.

ALL-IN-ONE 3D PRINTING SOFTWARE – FROM CAD TO G-CODE

The Simplify3D software suite contains everything you need to start making parts with your new 3D printer. Import your digital models/CAD data, select your pre-configured settings And generate your G-Code instructions in a few seconds. View an animated preview of your build sequence and start your 3D print knowing you have optimized your model for the best 3D printing quality possible!

Main product features:

- Intelligent support structure

- Variable slice settings

- Vary the layer height, speed, temperature

- Animated 3D Print Preview

- Advanced multi-component additive manufacturing

- Filling of different heights

- Works with most 3D printers

UNMATCHED PRODUCTION CAPABILITIES

Intelligent support structures

You control where the detachable support structures are positioned. Use mouse clicks to add or delete media based on your preferences. Save production time, save material And optimize your final part with supports that come off easily And in a clean way . This software is a must for large and complex 3D prints! Now split your CAD data into printable G-code.

Variable slice settings

Apply different cutting settings within the same part , for example a 40% fill base and 15% fill top.

Select your settings

You can vary the layer height, build speed, temperature, or any other setting to achieve incredible build quality. This feature is very useful for testing and calibration—apply a setting every 10mm and then evaluate the final part to determine the optimal 3D printing settings. This is a wonderful way to fine-tune the capabilities of your 3D printer.

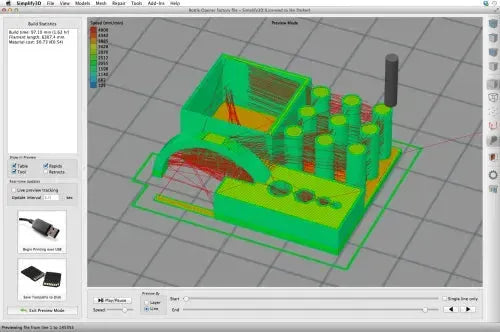

Animated 3D Print Preview

Watch a fast-forward virtual animation of your 3D model being built. Precise views allow you to view the sectioned CAD data layer by layer or row by row. This detailed view of the build process helps you identify areas for improvement before starting 3D printing with filament.

Advanced multi-part printing

Add 3D models as CAD data of your choice and let the software organize the parts to maximize the capacity of the print bed. You can also apply different settings for different models on the same print platform. For example, if you're producing three parts at once, you can choose settings that will optimize the 3D print quality of each part. The special multi-part 3D printing mode optimizes the frequency with which the 3D printer moves between parts to improve production quality and save 3D printing time. We simplify complex multi-part printing.

Thin outline, thick filling

Apply this setting to save time when using very fine outer layer heights. You can 3D print 3 very thin 0.1mm outline layers while processing 1 0.3mm thick infill layer. Activate this feature with just one mouse click and it can save hours of 3D printing time while still delivering a part with superior external detail.

Complete control over the starting stitch sewing

This new feature makes a huge difference in 3D printing quality by controlling the position of the starting point for each layer. Many people refer to the residue of a starting point as a pimple left over from your part. You can now choose between 3 options that control the position of the starting point.

- Make the starting points completely random to create a nice smooth exterior.

- Optimize all starting points for maximum production speed (and typically minimum bleed-through between layers); O

- Align all starting points to a specific position—this is one of our new favorites! For example, if you were producing four different parts, you could choose a different starting point position for each part and hide the transition marks in an unused area of each part.

HASSLE-FREE INTEGRATION

Best of all, Simplify3D software is specifically optimized for use with your new 3D printer. It already contains all the pre-configured settings you need to start 3D printing quickly and easily. Take your manufacturing experience to the next level and get started with Simplify3D software today!

For more information visit: http://www.simplify3d.com/

Detailed information about the software is available at: http://www.simplify3d.com/software/

Technical details

- The product is an electronic download that is sent via email immediately after purchase.

- The software is cross-platform and can be installed on Windows, Mac OS X or Linux systems

- System requirements: Intel Pentium 4 or higher processor, at least 2 GB of RAM. Windows XP or later, Mac OS X 10.6 or later, Ubuntu Linux 12.10 or later. OpenGL 2.0-compatible system.

- Improve 3D printing quality and save time and money

Get this slicer software for easy 3D printing. Simplify3D simplifies the CAD-to-G-Code process and offers many intelligent features.

Shipping and Warranty

Shipping and Warranty

All products available in stock will be delivered with an average timing of 24/48 hours.

Italy warranty with dedicated consulting support, contact us!

Share

-

Free shipping, return in 14 days *.

DisclosureFree express shipping for orders over € 499.

* For return terms and conditions, please visit our returns and refunds policy.

-

-

Are you a professional or a company?

Contact usYou can ask us for an invoice for your purchases! All the prices of our products already include VAT.

-

Do you have the teacher's card?

Contact usProceed with checkout and select "Teacher's Card" as the payment method. Requests?