3D Printing Materials Guide: Plastics

Share

Source: 3dnatives.com

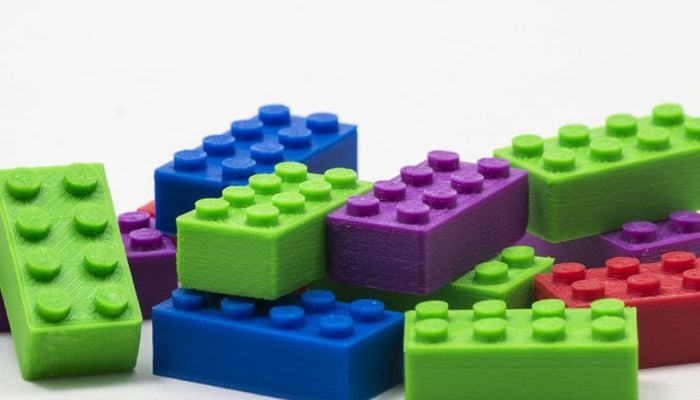

The plastics I am among the most used materials for the 3D printing . Due to their ease of production, versatility and impermeability, as well as their low cost, plastics are used in a multitude of products and sectors, that of Additive Manufacturing is no exception. Let's see together, in detail, what are the characteristics and applications of these materials. A plastic is a material made from synthetic or semi-synthetic compounds that has the property of being malleable (of changing shape). Most of the plastics on the market are entirely synthetic, that is, derived from petrochemical elements. However, given the growing concern for the environment, plastics derived from renewable materials such as polylactic acid (PLA) are also popular on the market.

In the following guide, we will take a look at the most common 3D printing plastics. As you may know, the most popular and cost-effective 3D printing process, FDM, produces parts by extruding plastic filaments. However, the accuracy on FDM machines is not the same as other processes such as SLS or SLA. So, for industrial and end-use parts, manufacturers mostly opt for SLS (using polymer powders) or SLA (using polymer resins) technologies, which offer higher precision and higher quality in the produced parts. Others 3D printing technologies with which plastics can be used are Material Jetting And Multi Jet Fusion.

Plastic filaments and pellets are available in different colors.

But which plastics can be used in additive manufacturing? In the form of filaments or powders, the plastic must be melted to form the printed object layer by layer. In the form of resin, it must solidify to form the object. Each plastic will require different 3D printing parameters during the production process and will give the parts different properties. Below we provide an overview of the different plastics that can be used in 3D printing.

ABS: The Most Used Filament Among 3D Printing Plastics

ABS filaments are the most widely used in 3D printing. They are used in car bodies, household appliances and mobile phone cases. It is a thermoplastic that contains a base of elastomers based on polybutadiene that makes it more flexible and resistant to impacts. ABS is also found in powder form for powder bed processes such as SLS and in liquid form for SLA and PolyJet technologies. ABS is used in 3D printing at a temperature between 230 and 260 °C. It is a resistant material, able to easily withstand temperatures from -20 °C to 80 °C. In addition to its high resistance, it is a reusable material and can be welded with chemical processes. However, ABS is not biodegradable and contracts when in contact with air, so the print bed must be heated to avoid deformations. In addition, it is recommended to use a closed chamber 3D printer to limit the emission of particles when printing with ABS. For further information please refer to our ABS guide.

ABS parts.

PLA

Known as polylactic acid or PLA, this material has the advantage of being biodegradable, unlike ABS. PLA is made using renewable raw materials such as corn starch. PLA is one of the easiest materials to print, although it has a tendency to shrink slightly after 3D printing. Unlike printing with ABS, when you print with PLA you do not need a heated bed. PLA also prints at a lower temperature than ABS, between 190 and 230 °C. PLA is a more difficult material to handle due to its high cooling and solidification speed. It is also important to mention that this material can deteriorate when in contact with water. However, the material is easy to use and comes in a wide range of colors, which makes it suitable for 3D printing with FDM. Makers often use PLA to make decorative objects or small toys, but this material is also used in the industry for prototyping. Find out more about PLA in our dedicated guide.

ASA

ASA is a material that has similar properties to ABS, but has a higher resistance to UV light. As with ABS, it is recommended to print the material on a heated bed to prevent any warping. When printing with ASA, you use similar print settings to ABS, but you must be very careful to print with a closed chamber due to styrene emissions. Learn more about this material in our ASA guide.

PET

Polyethylene terephthalate, or PET, is commonly found in disposable plastic bottles. PET is the ideal filament for any part that will come into contact with food. Additionally, the material is quite stiff and has good chemical resistance. For best results when printing with PET, we recommend printing between 75 – 90ºC. PET is commonly marketed as a translucent filament with variations such as PETG, PETE, and PETT. The benefits of PET include that the material does not emit odors while printing and is 100% recyclable.

3D printed bottles with recycled PET

PETG

PETG, or glycol-modified polyester, is a widely used thermoplastic in the additive manufacturing market, combining the simplicity of 3D printing with PLA with the strength of ABS. It is an amorphous plastic that can be 100% recycled. It has the same chemical composition as polyethylene terephthalate, better known by its acronym PET. The addition of glycol reduces its brittleness. Learn more about PETG in our dedicated guide.

Polycarbonate (PC)

Polycarbonate (PC) is a high-strength material designed for technical applications. The material has good temperature resistance, and can withstand any deformation up to about 150°C. However, PC tends to absorb moisture from the air, which can negatively affect performance and print resistance. Therefore, PC must be stored in airtight containers. PC is highly valued in the AM industry for its strength and transparency. It has a much lower density than glass and is therefore particularly interesting for the design of optical parts, protective screens or decorative objects. For more information, visit our PC guide to 3D printing.

A 3D printed piece with PC.

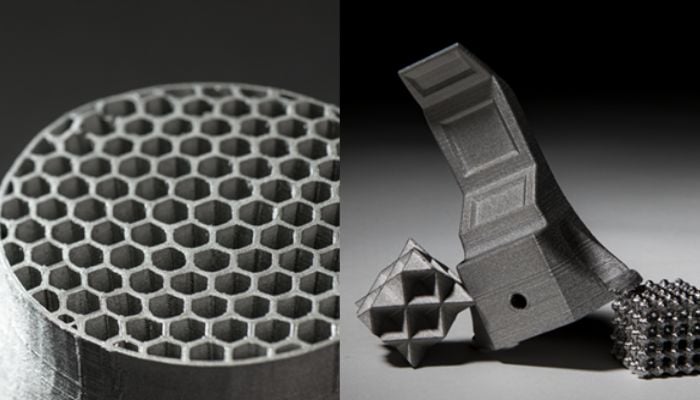

High performance polymers (PEEK, PEKK, ULTEM)

The evolution of 3D printing technologies has led to extensive research on printing materials, which has allowed the development of a complete range of high-performance filaments with mechanical characteristics similar to those of metals. There are numerous types of High-performance 3D printing plastics such as PEEK, PEKK or ULTEM – are distinguished by family as polyaryletherketones (PAEK) or polyetherimides (PEI). These filaments have very high thermal and mechanical resistance, are very robust and at the same time much lighter than some metals. These properties make them very interesting in aerospace, automotive and medical sectors .

Due to their characteristics, high-performance polymers cannot be printed on all FDM machines on the market. In fact, the 3D printer must have a heated bed capable of reaching at least 230°C, an extrusion at 350°C and a closed chamber. Today, approximately 65% of these materials are printed with FDM technology, but they are also found in powder form, compatible with SLS technology. Find out more in our guide dedicated to high-performance materials.

Credits: VisionMiner

Polypropylene (PP)

Polypropylene is another thermoplastic widely used in the automotive industry, professional textiles and in the production of hundreds of everyday objects. PP is known for its abrasion resistance and shock absorption, in addition to its relative stiffness and flexibility. However, the disadvantages of the material include its poor temperature resistance and sensitivity to UV rays, which can cause it to expand. For this reason, several manufacturers have developed alternative types of PP, similar to propylenes, which are more robust both physically and mechanically. More details in our PP guide for additive manufacturing.

Composite materials

Composite materials are extremely useful in creating extremely lightweight, yet strong parts. Fibers add strength to a part without adding weight, which is why we refer to composites as fiber-reinforced materials. There are two types of reinforcement: short fibers or continuous fibers. In the first case, chopped fibers that consist of segments less than a millimeter long, are mixed into traditional 3D printing plastics to increase the stiffness and, to a lesser extent, the strength of the parts. Chopped fibers can be mixed with thermoplastics such as nylon, ABS or PLA. Alternatively, fibers can be added to thermoplastics in a continuous manner to arrive at a stronger part. The main fiber used in the 3D printing industry is carbon fiber, but there are also other fibers such as fiberglass or Kevlar. Learn more in our composite materials guide.

Carbon fiber reinforced filament spool

Hybrid materials

Hybrid materials are made by mixing plastics and powders that give them a new color, finish, or additional properties. Often based on PLA, these materials are typically 70% PLA and 30% hybrid materials. For example, there are wood-based filaments available such as bamboo, cork, wood dust, and more. These wood-based materials mixed with PLA give the hybrid filament a more organic feel. Some hybrid materials contain metal powders to give the parts a metallic finish.

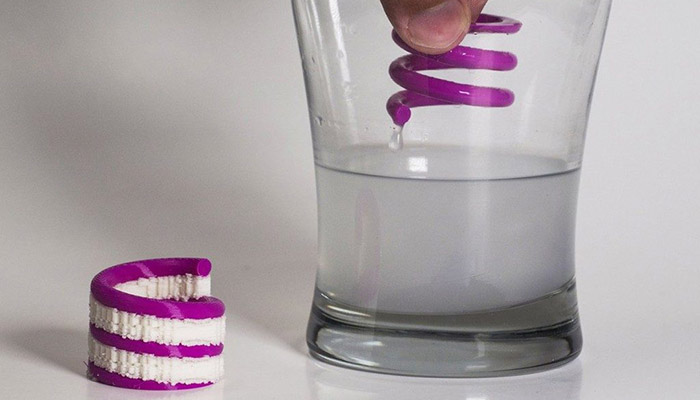

Soluble materials for 3D printing

Soluble materials are materials that are printed to dissolve at a later stage in the manufacturing process. The two most common soluble filament materials are HIPS (high impact polystyrene) and PVA (polyvinyl acetate). HIPS is related to ABS and can be dissolved with limonene, while PVA is related to PLA and can be dissolved with plain water.

There are also BVOH filaments, which are becoming increasingly popular, especially in dual extruder printers. This is because the material is soluble in water and according to experts has a higher solubility than PVA.

Flexible materials

Flexible filaments are similar to PLA, but are usually made of TPE or TPU. The advantage of using these filaments in 3D printing is that they allow the creation of deformable objects, which are widely used in the fashion industry. These flexible filaments generally have the same printing characteristics as PLA, but come in a number of different grades based on their stiffness. It is worth finding out which type of extruder is best for each material to avoid clogging when it comes to 3D printing.

Nylon

Objects made from polyamides (nylons) are usually created from a fine, white, granular powder using SLS technology. However, there are some variants of the material such as nylon that are also available in filaments used in fused deposition modeling (FDM). Due to their biocompatibility, polyamides can be used to create parts that come into contact with food (with the exception of foods containing alcohol). Made up of semi-crystalline structures, polyamides have a good balance of chemical and mechanical characteristics that offer good stability, stiffness, flexibility and impact resistance. Due to these advantages, the material has numerous applications in various sectors and offers a high level of detail. Due to their high quality, polyamides are used in the manufacture of gears, parts for the aerospace market, for the automotive market, robotics, medical prostheses and injection molds. More details in our nylon guide for 3D printing.

Alumide

Alumide objects are produced from a combination of polyamides and aluminum powder using the SLS process. The material has a large, slightly porous surface and a grainy appearance, which provides considerable strength and good resistance to high temperatures (up to 172°C). However, some post-processing treatments such as grinding, sandblasting, coating or milling are required. Alumide is used to produce complex models, design parts or for the small-series production of functional models that require high stiffness and an aluminum-like appearance.

https://3digital.tech

https://3digital.tech