SUPPORT FILAMENTS: EVERYTHING YOU NEED TO KNOW

Share

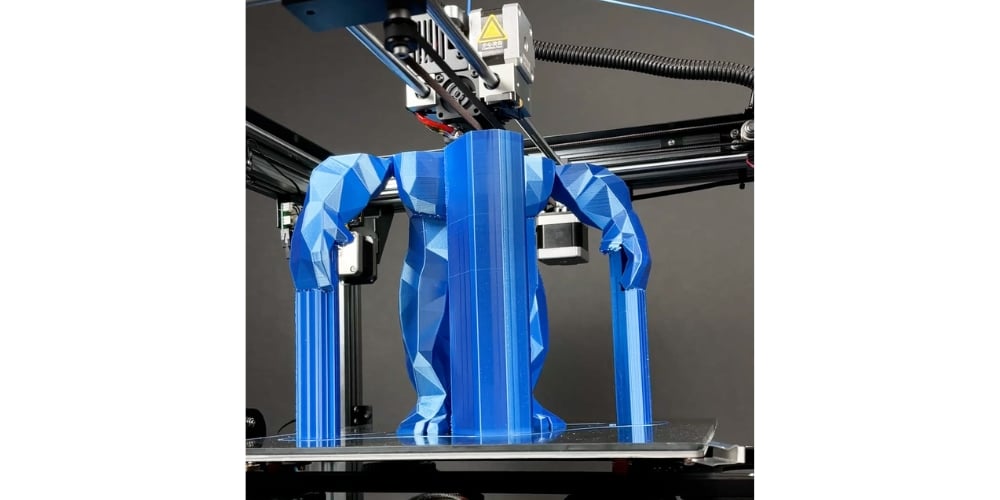

To make complex 3D prints, having support structures is essential. Thanks to them we can create complex geometries while keeping the aesthetics of the project intact. In this article we will talk about the best support filaments for making support structures, the alternatives available, best practices and how to solve problems. So, read this article carefully to find out how to make complex 3D prints.

Introduction to support structures

What are support structures?

Support structures are temporary constructions printed alongside the main model to ensure the stability of the print. If your model design involves complex geometry or protrusions, it needs adequate support to prevent it from sagging or collapsing. Support structures serve to hold more complex shapes and features in place until printing is complete.

After analyzing the design and the set parameters, the slicing software indicates the areas that require support and prints them together with the original model. These structures are manually removable or water soluble.

Importance of support structures in 3D printing

Support structures are extremely important for stabilizing certain parts of the print. They guarantee precise reproduction of complex details and allow you to obtain better quality models. Without support structures, it would be nearly impossible to reproduce complex figures in 3D prints. Support structures give versatility to 3D printing technology, amplify its functionality and facilitate the possibility of producing revolutionary objects.

Types of support materials

Depending on the project, different filaments are often used to make support structures for 3D printing:

PVA (Polyvinyl Alcohol)

Polyvinyl alcohol, otherwise known as PVA, is one of the types of support filaments used to make water-soluble support structures and has high compatibility, commonly used due to its excellent characteristics as a support. It dissolves easily in water leaving the print clean. You can use PVA with different filaments for printing.

HIPS (High Impact Polystyrene)

High impact polystyrene is another filament for making very compatible support structures, which dissolves smoothly into d-limonene leaving a uniform surface.

Separation of support structures

Basically, the filament chosen for the main project is used to create support structures and, once printing is completed, these are physically cut or broken. They are pretty easy to remove and are great for support.

Other types of material for support structures

In addition to the support structures mentioned above, the following are also used:

Nylon

Nylon is also widely used in support filaments, as it offers good support to overhangs and is soluble in solvents. You can also remove supports manually.

Metal support

This type of support is used in 3D printing jobs, such as selective laser melting, to hold metal parts. Normally, a metal powder similar to that used for the main printing is used to create these support structures. These metal supports are easily removable by sandblasting or electroerosion.

Brief overview of the additional support facilities available

Soluble support resins

Resin carrier filaments are used as carrier filaments for some technologies such as digital light processing. Some solvents are used to dissolve resin support structures.

FDM support structures

In FDM printing processes, filaments compatible with FDM technology, such as ABS or PLA, are used to make the support structures. Once the object is printed, you can remove these support structures.

Heat resistant support materials

Technologies such as selective laser sintering require high-temperature thermoplastic materials such as PEI to print support structures.

Working the PVA

When printing support structures for a model, there are a few things you need to keep in mind, such as print settings or how to remove support. In this section we will cover the best ways to work with PVA.

Print settings and considerations

PVA Printing Temperature: While printing temperatures can vary between filament brands, the ideal temperature usually ranges between 180 and 210 degrees Celsius.

Adherence to the bed: For best bed adhesion, use a heated platen and clean it before printing. You can also use a PVA-based glue to make the filament stick to the surface better.

Printing Speed: It is best to use a slower speed, preferably around 20-50% of the main filament, when printing support structures with PVA. This ensures better adhesion, precise deposition and maintains structural integrity.

Best practices for removing PVA supports

To easily remove supports, do this:

- Immerse the model in water so that the supports dissolve in it.

- Brush the media to speed up the melting.

- Change the water when it becomes cloudy with melted PVA.

- Rinse the model and let it dry completely.

- Apply post-processing techniques to achieve better surface finish.

Tips for optimizing PVA support structures

Use support filaments where necessary. Don't overuse supports because they can lengthen printing times and waste filament. To optimize the PVA support, you can:

- To preserve structural integrity, adjust the support density in your slicing software.

- To improve stability and adhesion, increase the area of the support interface.

- Prints at a slower speed for better adhesion and deposit.

- Increases the overhang angle threshold.

- Adjust the print temperature to minimize the chances of stringing.

- Check the printing process and fix problems.

Choose the right filament for the support structure

Factors to consider when choosing a filament for your support structure

It is important to choose a compatible filament for your print media, to prevent the removal process from becoming difficult. The factors to consider when choosing the right filament are:

- Make sure the support filament is compatible with the main filament.

- Evaluate the ease of melting the filaments or the post-processing steps.

- Choose a substrate filament that adheres easily to the object you want to print.

- To avoid clogging problems, the support filament and the primary filament must have similar or close printing temperatures.

- Evaluate the mechanical resistance of the support filament and check if it corresponds to the printing requirements.

- Some support filaments are ideal for creating prototypes in a short time, while others are more suitable for creating details. Then choose a perfect support filament for your printing project.

Compatibility with the printer and the main filament

The materials for the support structure must be sufficiently compatible with the primary filament and the printer, in order to guarantee the stability of the supports and optimal removal of the same. Check that your printer can withstand the temperature necessary to print with the support filament and that it is suitable for double extrusion.

Again, the co-presence of the support material with the main filament leads to better adhesion between the main print and the support.

Next, choose a filament that adheres properly to the main model.

Use cases and applications

Support structures are used extensively to print delicate models in various industries. Thanks to them, we can print complex models. The use of supports is very common in industries such as automotive or aerospace, where designs are often too complex. They are also widely used in the medical industry to produce prosthetics, anatomical models or surgical guides.

These support structures are also popular among students and architects for making architectural models and sculptures.

Conservation and treatment of support filaments

Storage tips to prevent moisture from being absorbed

- Store support filaments in a vacuum-sealed bag or airtight container.

- Add desiccant sachets inside the container to keep the filament dry.

- Store filaments in a cool, dry place, away from sunlight.

- Install a humidity sensor in the room where you store them, so you can intervene more quickly if the temperature changes.

- Purchase filament dryers or dry boxes used to absorb excess moisture and keep the filament dry.

Proper processing techniques to maintain filament integrity

- Store the support material in an airtight container and add a few sachets of desiccant to keep the interior environment dry.

- Use gloves because touching the filament directly can transfer moisture or grease to the filament.

- Keep the nozzle clean to improve filament extrusion.

- Make sure the filament spool is positioned carefully to prevent tangling.

- To maintain the quality of the filament, make sure the printing environment is stable.

troubleshooting

Some problems are quite common when it comes to printing support structures and are not particularly different from those of regular 3D printing. These are:

Adhesion problems

Support filaments often fail to adhere to the build surface when the build surface is not heated enough, is not leveled properly, or has debris. To overcome this problem, it is a good idea to keep the work surface clean, use adhesive aids such as hairspray and make sure that the leveling is correct.

Stringing

High print temperature and incorrect retraction settings are the cause of stringing. Calibrating the print speed, temperature and retraction distance can solve the problem.

Obstruction

Filament residue left over from previous prints often causes this problem, which can be resolved by fine-tuning the printing temperature, using the right size nozzle, and keeping it clean at all times.

Frequent questions

What is a support filament?

Support filaments are temporary filaments used to print composite support structures and overhangs. They are generally soluble in water and therefore easy to dispose of after printing.

What is the best support filament for PLA?

PVA is the support filament most compatible with PLA due to its solubility in water, its ease of adhesion and compatibility with printing temperature.

What is the best support filament for ABS?

HIPS is best for ABS filaments, as both filaments have the same printing temperature. Furthermore, HIPS dissolves easily in solvents such as limonene.

Support structures allow us to add innovative and complex shapes to our 3D prints and this is why industries such as aerospace or automotive use them to print functional parts. When printing support structures you need to pay attention to the choice of support filament.

Consider the factors we have outlined in the article and choose carefully. We hope this article can be useful.

https://www.instagram.com/3digital.tech/

https://www.instagram.com/3digital.tech/