Comparison between Creality Ender 3 V3 SE and Ender 3 V3 KE

Share

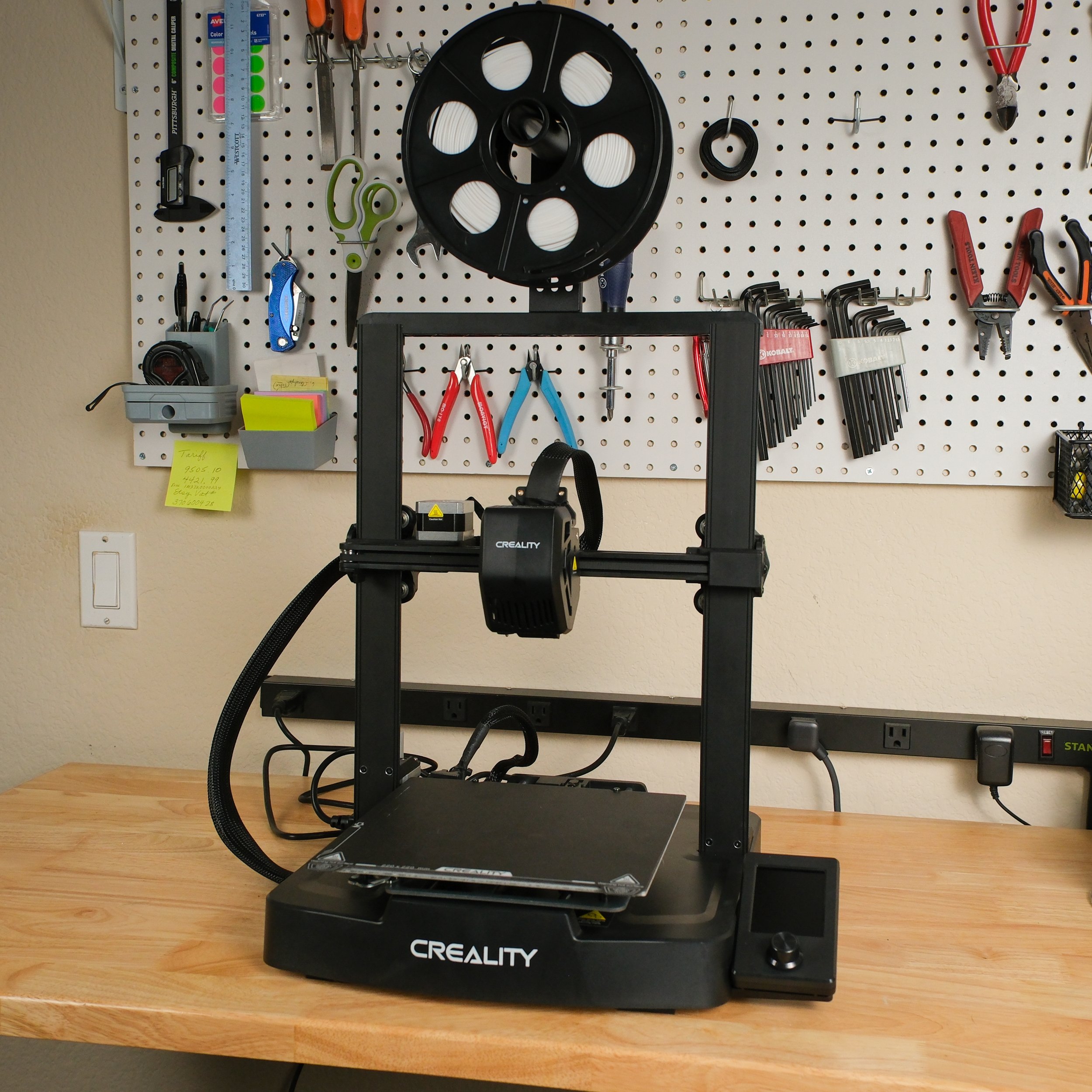

Creality recently released two new 3D printers in the Ender 3 range, the Ender 3 V3 SE and the Ender 3 V3 KE. These machines are similar in many ways, and in this article we will explain the differences between them to help you determine which of these machines is best for you.

Both the Creality Ender 3 V3 SE and Ender 3 V3 KE were released in fall 2023. Here are the key specs in brief:

|

|

|

|

Similarities between Creality Ender 3 V3 SE and Ender 3 V3 KE

The Creality Ender 3 V3 SE and Ender 3 V3 KE are part of the same Ender 3 family and share many of the same basic design elements. We will cover the main similarities in this section.

Build volume

The Ender 3 V3 SE and Ender 3 V3 KE have very similar build volumes, matching most other printers in the Ender 3 series:

-

Ender 3 V3 SE: 220 x 220 x 250 mm

-

Ender 3 V3 KE: 220 x 220 x 240 mm

Both printers use the Sprite direct-drive extruder, which we found reliable and easy to use.

There is a slight difference in Z-axis build volume, which we note in the Differences section below, but these printers essentially offer the same build volume. We've found this to be a good versatile size that allows you to print many types of 3D models without needing to find desk space for a large 3D printer. However, if you want to print very large models, one of Creality's larger 3D printers is likely to be a better choice, such as the Ender 3 S1 Plus or CR-M4 [Amazon links].

Direct drive extruder

Both printers include Creality's Sprite direct-drive extruder, which is a substantial upgrade over previous entry-level Creality 3D printers. In our experience, the Sprite extruder is extremely reliable, with much less chance of jamming than Bowden extruders. It also makes the printer much more capable of printing flexible filaments, such as TPU. We're happy to see the Sprite extruder on printers in this price range.

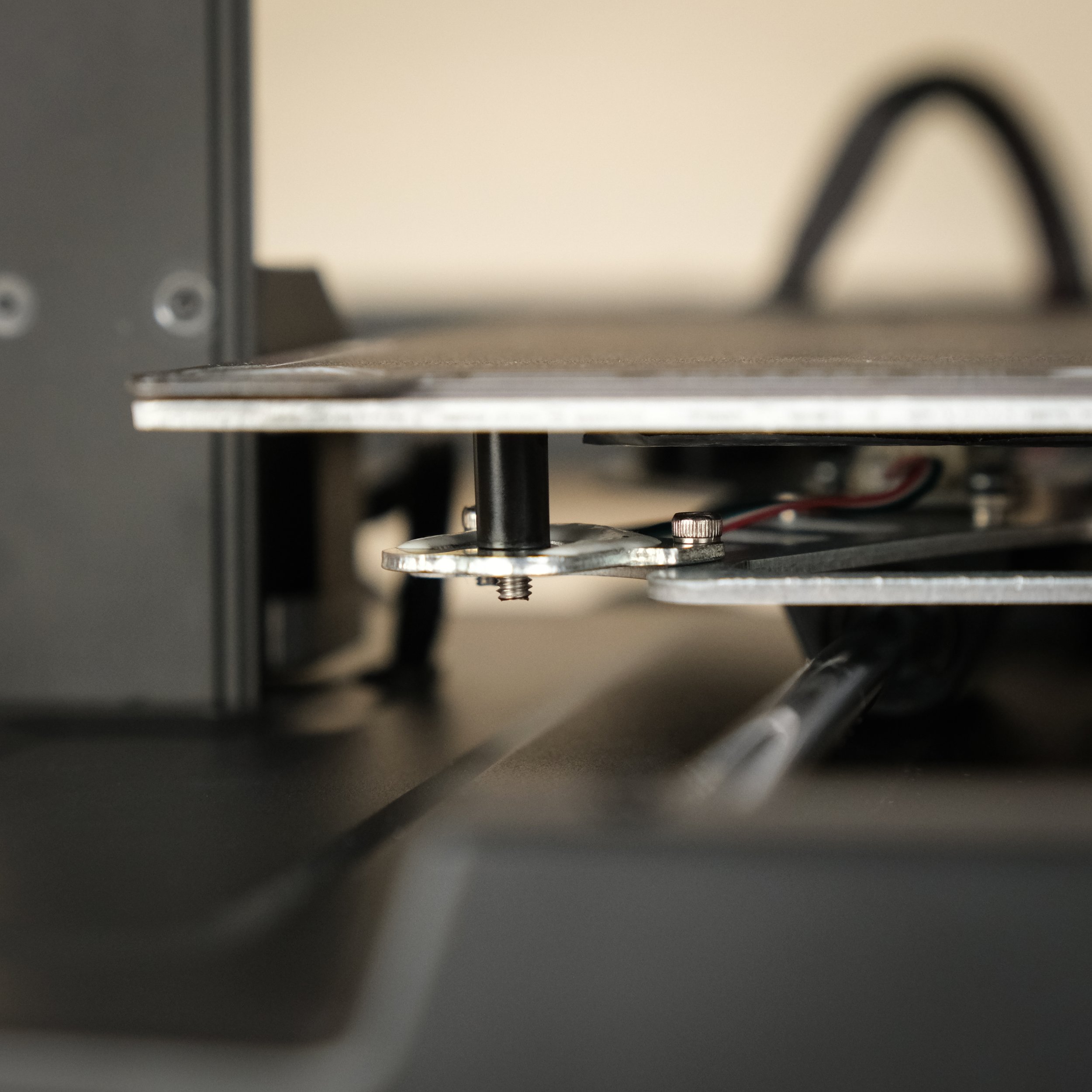

Automatic bed leveling

The Ender 3 V3 SE and Ender 3 V3 KE both include automatic bed leveling with the Creality CR-Touch bed leveling sensor. Automatic bed leveling probes the print bed in a grid pattern before printing, allowing the printer to compensate for any leveling issues to ensure a more consistent first layer and more reliable printing. We appreciate automatic bed leveling as a convenient feature that makes printer calibration easy, and the CR-Touch is our favorite bed leveling sensor thanks to its reliability and metal probe.

Both printers also include a new strain gauge sensor on the build bed that allows the printer to automatically set the Z offset. On older Creality 3D printers, you had to manually configure a Z offset value using the controller, to tell the printer exactly how much distance there was between the tip of the probe and the nozzle itself. V3 SE and KE can automatically set this offset by using the strain gauge to detect when the nozzle touches the bed. This saves another calibration step.

Movement system

Both the Ender 3 V3 SE and the Ender 3 V3 KE use a standard Cartesian motion system, where the carriage moves left and right on the The X axis lifts on a gantry along the Z axis. This is by far the most common motion system for consumer 3D printers and has been used in the past on many Creality 3D printers.

Both printers use linear rods for the Y-axis, which reduce vibration when printing at high speeds – this is a first for the Ender 3 series and is likely a contributing factor to the high maximum print speeds of both printers .

Additionally, both printers are equipped with two Z-lead screws, which ensure uniform lifting of the gantry on both sides. Since the Sprite direct-drive extruder is heavier than a Bowden extruder, the double-Z screws help manage the additional weight and ensure a smooth print as the pattern grows upwards. Interestingly, both printers implement this with a single Z-motor and connect the two lead screws together with a belt at the top of the printer. It's a clever design that eliminates the need for a second motor and ensures the two lead screws are always in sync, and we saw good results from this system in our tests of the SE.

Both printers are equipped with Y-axis linear rods, which reduce vibrations at high speeds.

The two Z-screws are driven by a single motor and are connected with a rubber belt at the top of the printer.

There is a slight difference in the motion system between the two printers: the KE uses a linear guide on the X-axis, while the SE uses a standard rubber wheel that slides along an aluminum extrusion. We will cover this difference and its implications later in this article.

Next, we'll cover the differences between the Ender 3 V3 SE and the Ender 3 V3 KE.

Differences between Creality Ender 3 V3 SE and Ender 3 V3 KE

The Creality Ender 3 V3 SE and Ender 3 V3 KE have several important differences that impact the printing speed, capabilities, and user experience of each 3D printer. In this section, we'll cover each of these differences and explain the details of each.

Controls and firmware

The Ender 3 V3 KE includes significantly more advanced firmware than the Ender 3 V3 SE. Creality refers to it as "Creality OS", but it appears to be the same firmware found on the CR-10 Smart and the Creality Sonic Pad. This firmware, based on the open source Klipper project, enables some key features that improve usability and KE print quality.

The Klipper-based firmware has significantly more processing power than the standard firmware used on most other Creality 3D printers, which allows the Ender 3 V3 KE to print at high speeds without introducing print defects. Combined with some hardware improvements we'll talk about later, this feature allows the KE to print significantly faster than the Ender 3 V3 SE, which was already much faster than older Creality 3D printers. To further improve performance at high speeds, an optional vibration compensation sensor can be added to the KE to further optimize the firmware. This is not supported on Ender 3 V3 SE.  This display, on the Ender 3 V3 SE, is more advanced than many of Creality's older printers, but is less capable than the KE model's touchscreen display.

This display, on the Ender 3 V3 SE, is more advanced than many of Creality's older printers, but is less capable than the KE model's touchscreen display.

The latest firmware of the Ender 3 V3 KE also improves the usability of the printer, both in direct control and remote monitoring. On the printer itself, KE includes a 4.3" touchscreen controller that we prefer over the smaller 3.2" screen and knob controller on the Ender 3 V3 SE. Both printers have clean user interfaces and display more information than we've seen on older Creality 3D printers, but the KE is able to display more information and display it more clearly thanks to its more advanced firmware.

As a result of the firmware, the KE also introduces remote control and monitoring features not found on the SE. Includes WiFi, allowing you to connect to the printer wirelessly to view its status from a smartphone or computer. You can use the WiFi connection to upload .gcode files for printing, as well as use the printer remotely or monitor the progress of an ongoing print. The KE also supports a USB webcam, which allows you to view your print remotely. While these features aren't necessary for 3D printing, we definitely appreciate these additional features. In particular, uploading files over WiFi reduces one of the biggest annoyances of 3D printers: carrying an SD card back and forth from the computer or keeping the printer connected via USB while printing.

Firmware controls and features are one of the biggest differentiators of the Ender 3 V3 KE compared to the Ender 3 V3 SE. While the SE provides a solid foundation of features in its firmware, the KE is clearly more advanced, offering higher quality prints and useful features like WiFi control.

Printing speed Even at high print speeds, these printers can produce exceptional prints. These parts were printed at 175 mm/s.

Even at high print speeds, these printers can produce exceptional prints. These parts were printed at 175 mm/s.

The Ender 3 V3 KE advertises a much higher maximum print speed than the Ender 3 V3 SE. The KE advertises a maximum print speed of 500 mm/s and a typical speed of 300 mm/s , while the SE advertises a maximum print speed of 250 mm/s and a typical speed of 180 mm/s. We never like to completely trust maximum print speeds, because that speed is often only achievable on certain 3D models or introduces more print defects. However, we find the typical print speed to be more reliable: we tested our SE at the "typical" print speed of 180mm/s and the resulting print maintained a high level of quality. So while you may not consistently print at 500mm/s with the KE, it's noticeably faster than the SE.

The KE is capable of achieving faster print speeds through a combination of firmware and hardware updates. First, as we described in the firmware section above, the Klipper-based firmware in the Ender 3 V3 KE is more sophisticated and includes features to reduce print defects when printing at high speeds. Additionally, the KE uses a linear guide for the X-axis, which reduces vibration and allows the carriage to move more smoothly along the axis at high speeds. The SE uses a standard rubber wheel system on the X-axis.

It's important to note that both the Ender 3 V3 KE and Ender 3 V3 SE are capable of printing much faster than older Creality machines like the original Ender 3 or CR-10. Most older 3D printers weren't capable of reliably printing above 60-70mm/s, and even the SE can print at about triple that speed. However, if you want the fastest possible printing, the KE will be the best choice.

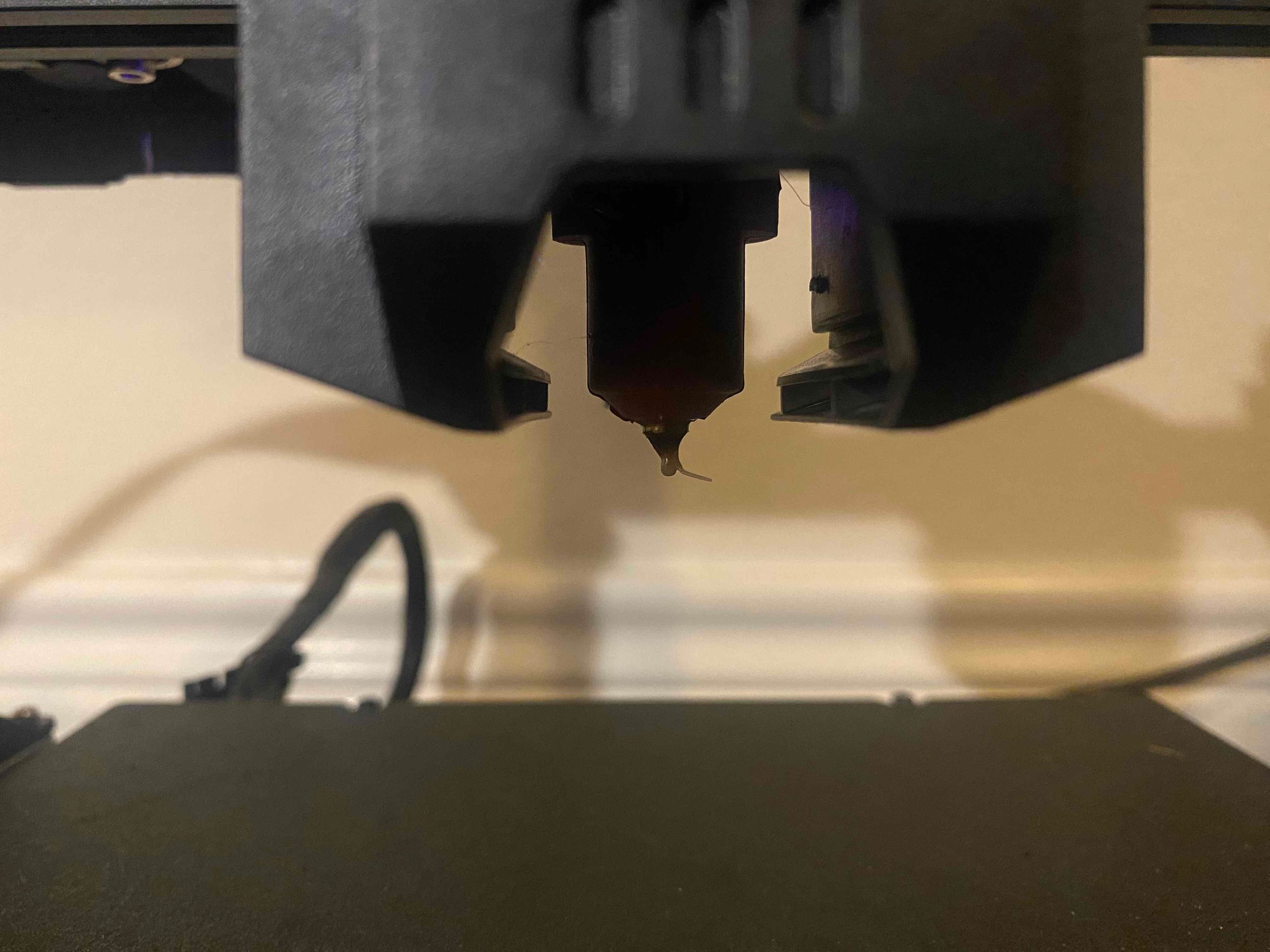

Hotends

The Ender 3 V3 SE's hotend is a newer variant of Creality's Sprite extruder and hotend system and is capable of heating up to 260°C. This makes the SE capable of printing all types of filaments standards, including PLA, ABS, PETG and TPU. However, it cannot print high-temperature materials, such as nylon.

The Ender 3 V3 KE uses an updated version of the Sprite hotend that is capable of heating to a higher temperature of 300°C. It has a more powerful 60W heater (compared to the SE's 40W) and uses a "Volcano" style design with a larger heat zone than a normal hotend. This means that the hotend can heat the filament faster, which is important for high-speed printing.

The KE's hotend also includes a bimetallic heatbreak, which is a technology we've previously tested on older Creality machines and found to reduce the chance of hotend jams. We don't think hotend jams are a big issue for any of these printers since they use the Sprite direct-drive extruder, but the bimetal thermal cut should still improve hotend performance with high-temperature filament.

For many users, this won't be a significant difference: the standard filament types all work well on both machines, and we find that we mostly use standard filament types, like PLA. However, the Ender 3 V3 KE gives you the ability to print high-temperature filaments, such as nylon.

Cooling of parts

Like almost all modern 3D printers, the Ender 3 V3 KE and SE both include a part cooling fan, which blows cool air onto the filament as it's extruded, improving overhang performance and generally producing cleaner prints. We've found that the placement of the parts' cooling fans and the geometry of the cooling ducts can play an important role in the effectiveness of this feature, and the two printers definitely implement it differently.  Illustration of SE model parts cooling inconsistencies. The only difference in these prints is the orientation on the print bed. The KE model appears to have more complete part cooling and should provide consistent results regardless of how the part is oriented.

Illustration of SE model parts cooling inconsistencies. The only difference in these prints is the orientation on the print bed. The KE model appears to have more complete part cooling and should provide consistent results regardless of how the part is oriented.

The KE uses a dual-part cooling fan design that is more effective than the SE's single fan.

The SE includes a one-piece cooling fan that blows towards the nozzle from the front. We noted in our review of the Ender 3 V3 SE that the part's cooling performance differs depending on how you orient the part on the print bed, likely because the cooling fan only blows from one side of the print. Overall, we find the SE's partial cooling to be effective, but not great.

With the Ender 3 V3 KE, Creality seems to have attempted to solve this problem by adding a second cooling fan. The two cooling fans are located on both sides of the hotend and blow towards each other, which should cause the part to be cooled more evenly. We haven't had the opportunity to test it out ourselves, so we can't say for sure that it fixes the inconsistencies we found with the cooling portion on the SE. However, the KE appears to have a better design that should cool the part more effectively.

Bed surface

Both printers include a flexible magnetic bed surface, which can be easily removed to facilitate parts removal, as well as facilitating material replacement or upgrades. However, there is an important difference in the default bed surface included with each machine.

The Ender 3 V3 SE includes a PC spring steel bed surface, which has a textured coating. While we have found this bed material to have excellent layer adhesion and have seen generally good performance, it is not our favorite bed material because sometimes parts can stick too well and it is possible to damage the liner when removing the sheets. set off. For this reason, we recommended SE users consider upgrading to a PEI bed surface , which can be easily installed as the surface attaches magnetically to the print bed.

On the other hand, the Ender 3 V3 KE includes the PEI bed surface by default. We prefer PEI because it has a smooth finish that makes the base of 3D prints look nice, but releases the prints easily once the bed has cooled. This is a nice upgrade over the PC spring steel bed surface on the SE.

Dimensions and build volume of the Z axis

The Ender 3 V3 SE and Ender 3 V3 KE differ slightly in Z-axis dimension, with the KE being 10mm shorter in Z dimension:

- Ender 3 V3 SE: 220 x 220 x 250 mm

- Ender 3 V3 KE: 220 x 220 x 240 mm

In terms of size and desktop footprint, the two printers have a slightly more notable disparity, with the KE being a bit larger:

- Ender 3 V3 SE: 349 x 364 x 490 mm

- Ender 3 V3 KE: 433 x 366 x 490 mm

The significance of this slight difference in width depends on where you plan to place the printer. The KE is only about 3.2 inches wider, but if you're short on desk space or are trying to fit multiple printers on a shelf, the KE's larger footprint could be a factor.

Filament exhaustion sensor

The Ender 3 V3 KE includes a filament run-out sensor, while the Ender 3 V3 SE does not include the sensor and instead offers it as an optional upgrade.

In our opinion, the filament runout sensor is not a particularly beneficial addition to Creality 3D printers. We found that when the sensor detects that the filament has run out, it stops printing and cools the bed, thus releasing the printed model and making it impossible to resume. For this reason, unless you monitor your printer closely and notice the moment when filament running out is detected, you are unlikely to save a print. So while this is a small added advantage over the KE, we don't think this is a significant difference between the two printers.

Which printer should you choose?

The Creality Ender 3 V3 SE and Ender 3 V3 KE both offer an impressive feature set compared to previous printers in Creality's Ender 3 range. We were excited to see the improvements made to the V3 SE when it was released, and the V3 KE sits well above it with several notable upgrades and a higher price to match. We think either machine would make a great first (or second, third, or tenth) 3D printer, and we don't have any major issues with either machine.

However, the KE clearly offers significant additional capabilities over the SE. Of the differences, we think the firmware improvements and faster maximum print speed are the main reason to choose the Ender 3 V3 KE over the SE. The Klipper-based firmware in the KE allows for faster, cleaner prints, and features like WiFi printing make it feel like a more modern machine. Print speed improvements, along with the addition of linear guidance on the X-axis, will allow you to print faster, reducing one of the biggest annoyances of 3D printing. The other improvements in the KE, such as the upgraded parts cooling, high-temperature hotend, and PEI bed surface, are also all significant improvements that you will likely appreciate.

On the other hand, the Ender 3 V3 SE is priced lower than the KE model and offers many of the same core features, such as the Sprite direct-drive extruder, automatic bed leveling, and faster print speeds than many older ones. Creality 3D printers. . In our testing so far, it's been a reliable, easy-to-use machine that produces great results.

Our opinion is that the Ender 3 V3 KE is worth the extra cost for most users. It has some of the key upgrades that you might want to add to the Ender 3 V3 SE eventually, and generally has a more advanced feature set that makes it competitive with 3D printers that are much more expensive. However, if you can't find a KE in stock or the price difference between machines is a major factor in your decision, the SE is also a solid choice.

https://www.instagram.com/3digital.tech/

https://www.instagram.com/3digital.tech/