DRONES IN CONSTRUCTION

USE OF DRONES IN CONSTRUCTION

Improve efficiency, improve safety.

Drones can save tens of thousands of euros a week

Drones are becoming an essential tool on construction sites.

Indeed, the fastest growing commercial adoption of drones is the construction sector.

Drone data can benefit construction companies in a number of ways. It can be collected safely, quickly and accurately to help companies track their on-site progress, streamline communication and decision-making, pinpoint errors, create detailed maps and 3D models, and keep field personnel out of dangerous.

Deploying drones for construction can help save money over the lifecycle of a project and can be far more efficient than traditional methods, in some cases taking hours to collect data, rather than days.

Simply put, drones have become a critical part of a worker's toolbox.

As Komatsu's Richard Clement says: “Thanks to drones and associated software, data can be collected from a site in half an hour, compared to three days with traditional handheld methods. Drones enable businesses to create highly accurate maps and point clouds, uncover costly construction site errors and predict planning delays, saving up to tens of thousands of pounds a week.

Cost savings

DJI M300 RTK and H20 saved oil giant Shell $100,000 in a single use.

Efficiency gain

Drones collect solar panel data over 50 times faster than manual methods.

Trusted data

Drone inspections in the energy sector provide a higher level of detail than traditional methods.

Reduced risks

“Drones increase safety and keep employees away from dangerous areas” – Rio Tinto.

Benefits of drones under construction

Drones can be used on construction sites for a variety of tasks. These include:

- Initial Site Survey/Measurements - Assess large construction sites and provide detailed and accurate data to architects and contractors before setting foot on site. This gives companies the competitive edge right from the bidding process.

- Mapping/Construction Modeling - Drone data can be converted into detailed maps and 3D models to help with project tracking and accurate measurement of distances, land areas, elevations and volumes.

- Progress Monitoring : Access real-time aerial data to understand what's happening on site. This is ideal for monitoring progress and spotting errors before they become too costly.

- Inspection : inspect roofs or building facades to collect a large amount of information with zoom or thermal cameras. Drones eliminate the danger of manual data collection and are a much more efficient way to collect this information.

- Security/Maintenance : Drone images can highlight any on-site issues, such as a damaged section of perimeter fence. A drone with a thermal imaging camera can spot problems like tank overheating, which may not be detected with the naked eye.

- Access hard-to-reach areas : Drones eliminate the need for ground personnel to climb potentially dangerous stockpiles, venture into hard-to-reach areas or climb scaffolding. This improves workplace safety.

“A photo of a drone is potentially worth millions of euros”

Drones provide a bird's eye view of a construction site, providing full site awareness through regular shareable site maps.

Access to top views of a site helps teams track site progress over time; ideal for controlling timelines and making sure your project hits deadline.

A top view can also be used to spot any errors or problems. This means that problems can be identified much quicker than traditional methods and can be addressed before it's too late, saving time and money. These images can be used in CAD overlays, overlaying original designs to spot any errors and identify if the design deviates from the initial proposals.

Aerial data also makes intra-site communication incredibly simple, keeping staff updated on the current status of operations and allowing stakeholders to stay abreast. As an added bonus, staff and stakeholders can access this information remotely without having to set foot on site.

Drone imagery reduces guesswork or misinterpretation, which can lead to costly mistakes. Having such a large visual representation of a site is invaluable for project management and subcontractors.

Having aerial drone footage is also essential to increase safety, as colleagues don't have to venture to a dangerous construction site to get an overview of the project's development.

“Regular drone images provide a log for the duration of a pattern. It allows us to monitor and review progress, and we can reference a particular time frame at any point in the project lifecycle. We can see at a glance where we are with the project and can demonstrate this to the client, staff and stakeholders. It means the team can be aware of what's happening without having to travel to site."

Wayne Hughes, UAV lead pilot, Balfour Beatty

“When you have this documented progress of the site, you're able to go back in time and look at what was going on at any moment. Progress is digitally locked and you can go forward and backward. You no longer have to rely on interpreting a few notes on a bit of paper – using drone data gives you a clear and accurate picture.”

Jono Millin, co-founder and CCO, DroneDeploy

BETTER EFFICIENCY

Save time and money.

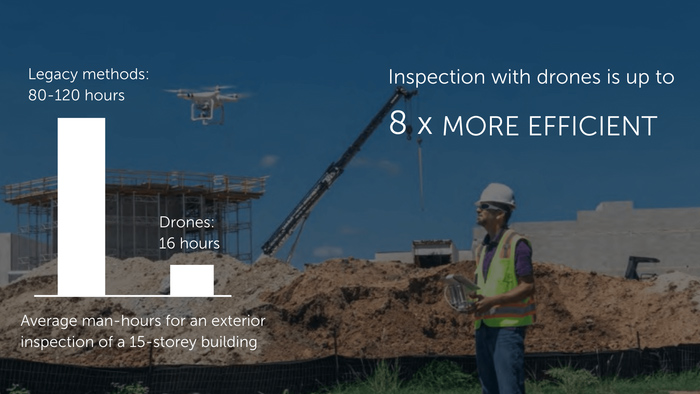

Drones can be 8 times more efficient for inspection

Construction projects can go over budget and be behind schedule. But drones help bridge this gap.

Drones are far more efficient than traditional methods, saving time and ultimately money.

Thanks to drone technology, it is possible to collect accurate data in a single flight, saving many hours on manual methods on the ground. In a single flight, a drone can acquire a large amount of information that can be used on a construction site and throughout the lifecycle of a project.

After all, why walk around a construction site – time consuming, labor and dangerous – collecting various images or multiple data points, when a drone can do it for you in a fraction of the time and without the added risk?

Drones can also increase efficiency when it comes to site inspections by capturing high-quality aerial images quickly and safely.

Building inspections often require teams to use manual rope access techniques that require traversing roofs and scaffolding, which is time consuming, expensive and dangerous.

But drones can be complemented with high-class zoom and thermal cameras that can capture accurate data in a single flight, helping to detect physical, water or electrical damage on roofs and facades. A drone's real-time video transmission also provides this information on demand, helping to make faster decisions, all while personnel remain safely on the ground.

DRONES ON SITE REDUCE THE RISK

Falling from a height is one of the most common causes of death. Drones can prevent that.

Construction is a dangerous sector

Construction sites can be dangerous places and risks are everywhere.

Figures released by the HSE showed 40 construction workers died in 2019-20, with the death rate four times the rate for all of industry.

The three most common causes were workers falling from heights, workers being hit by a moving vehicle, or being hit by a moving object.

This is why drones are becoming an increasingly important tool for construction. By deploying drones on a construction site, ground personnel are removed from potentially dangerous areas. The benefits of using UAS include:

- Staff no longer have to climb over stockpiles to pick quantities – a drone will do it for you.

- Staff don't need to enter certain areas of a construction site, risking collisions with vehicles and navigating difficult and dangerous terrain – a drone will do it for you.

- Staff don't need to work at height, climb scaffolding, use rope access methods or try to access awkward inspection points – a drone will do it for you.

- Personnel need not be put at risk when trying to detect hazardous materials – a drone can do it for you.

- Staff need not risk being hit by falling debris – a drone will collect the data you need for you.

- Personnel do not need to access all parts of a site to lay down Ground Assembly Points (GCPs) for surveying – a PPK/RTK capable drone dramatically reduces the number of GCPs needed.

When security is a top priority, the use of drones should be an essential component of a company's technology strategy to mitigate risk.

As the Center for Disease Control states: “Drones could help reduce construction-related injuries and death from falls, exposures to toxic chemicals, electrical hazards, or traumatic injuries from vehicle and equipment collisions.”

DIGITALISE YOUR SITE

Transform drone mapping data into 3D models and 2D maps.

Build detailed plans for actionable insights

Drones have the distinct advantage of enabling builders to digitize their job site, providing a range of results that can be used for analysis, evaluation and decision making.

Thanks to the highly detailed and comprehensive survey data collected by drones, surveyors and CAD technicians can be sure that they are collecting all the data in one go without having to go back to the construction site to gather additional information, saving time in the process.

In a single flight, a drone can acquire a multitude of accurate information, such as crisp and clear visual images, as well as georeferenced data that can be processed using photogrammetry software. This is useful for:

- Building digital terrain and surface models:

- Conduct mass, distance and volume calculations;

- Building Information Modeling (BIM) and 3D reconstructions

- 2D maps and orthomosaics

- CAD Overlays: The process of taking a photo of the site as it stands and putting the design plans in front

This information provides an excellent overview of a site, as well as a good basis for project management, regular coordination and project reviews.

Key Findings

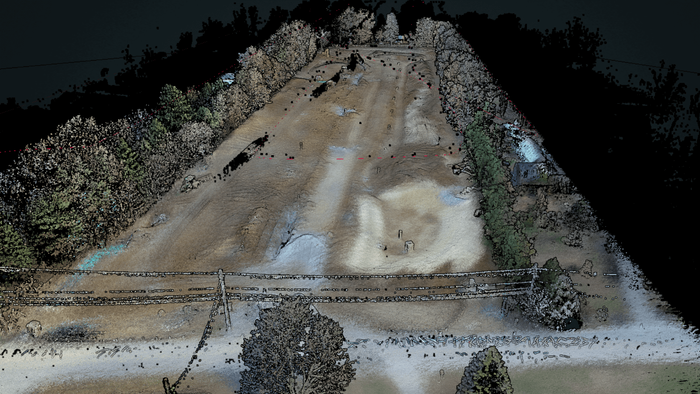

2D Map/Orthomosaic

A drone can capture hundreds or thousands of digital photos which can be used to produce high quality 2D orthomosaic maps.

This provides a real world view, aiding quick decision making and analysis of a project's progress.

These images can also be overlaid onto projected projects to act as a

Each pixel contains 2D geographic information (X, Y) and can directly provide accurate measurements, such as distances and horizontal surfaces.

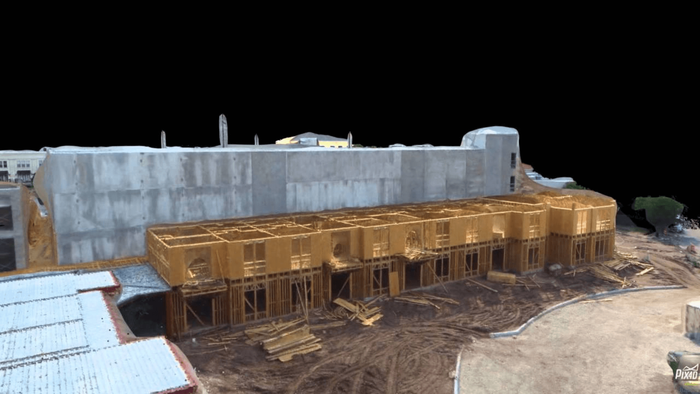

3D reconstruction

Using drone images, construction professionals can build 3D reconstructions of a site or parts of it.

3D models are ideal for site inspections and for visualizing how buildings or structures will look in the real world. Interactive maps even allow observers to see a 360° view of these reconstructions.

3D models are invaluable for visual inspection or when input from external stakeholders or audience engagement is essential.

The 3D data also enables the creation of digital surface models (DSM), digital elevation models (DEM) or digital terrain models (DTM).

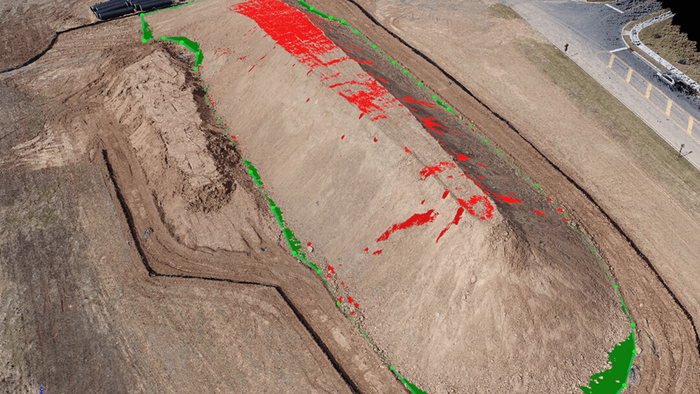

Volumetric surveys

Drones can be used to create volumetric models, which are useful for inventory measurements, for example.

Balfour Beatty used drones for inventory volume calculation and demonstrated how effective UAS can be for this application.

In Balfour Beatty's experience, traditional handheld methods can take a surveyor a day, but a drone can collect this data in 15 minutes and a model can be processed in two hours, resulting in huge efficiency gains.

In addition to volume measurements, drone data can be used to measure distances, areas and elevations.

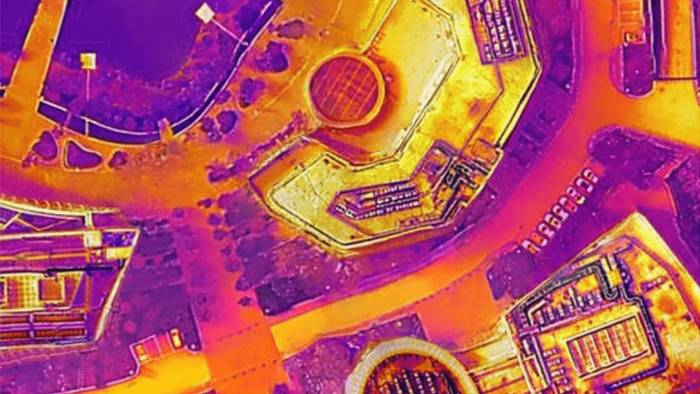

Surveys with thermal images

A thermal imaging investigation can uncover or diagnose problems that have not yet physically manifested themselves.

Thermal imaging cameras can identify problems such as heat loss; water leaks or moisture infiltration; failure of wiring and other electrical components; mechanical component failures, including overheating; overall performance and losses in underfloor heating pipes; and the success of energy efficiency improvements.

LiDAR Point Cloud

A LiDAR point cloud can be critical to construction and infrastructure projects, helping build 3D models and digital twins ideal for BIM applications.

These digital templates can be used throughout the entire lifecycle of a scheme, allowing teams to scan for quality assurance, cross-check templates and spot errors before they become a problem, lead inventory volumes and monitor the progress of a development.

Visual images

Drones can be used for visual surveys. High-quality aerial images are ideal for inspections, checking for defects and tracking progress.

Using a drone to do this is more efficient, cheaper, and safer than traditional methods.

Since a drone is a cheap and accurate way to collect visual data, regular visual surveys can be done.

DRONE MAPPING FOR CONSTRUCTION

It helps in acquiring accurate data.

How drone surveys can streamline workflows on construction sites

Drone mapping can play an important role on construction sites, helping to collect key data to create maps, models and visualizations that are crucial for communication, progress tracking and decision making.

Drone surveying solutions can produce varying degrees of accuracy, depending on project requirements.

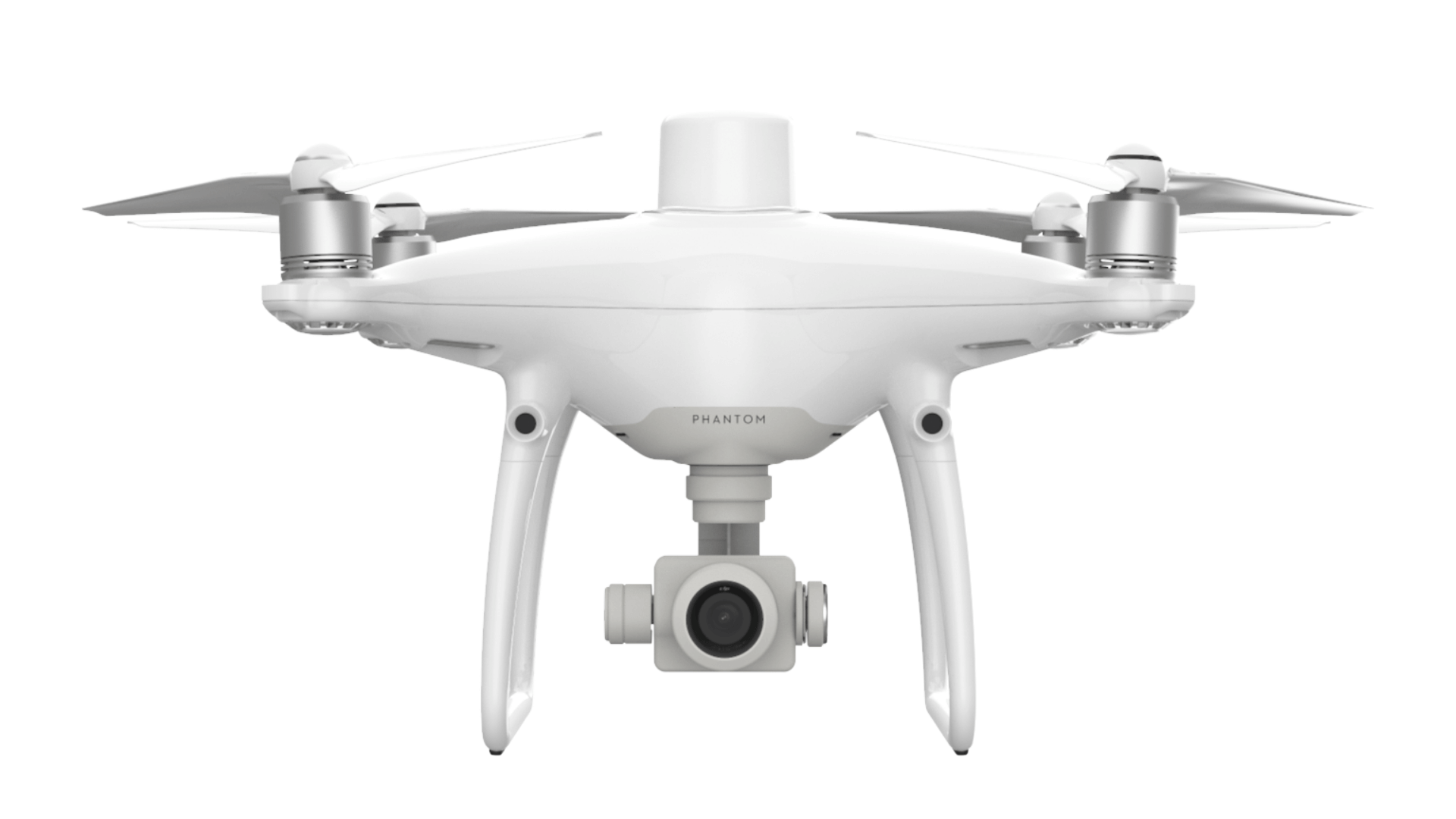

In an independent study, the DJI Phantom 4 RTK achieved a relative vertical accuracy of 2cm and a relative horizontal accuracy of 1.20cm.

An accuracy report also showed that the DJI Phantom 4 RTK can achieve an accuracy of 3cm-4cm without the need to place ground control points.

RTK can reduce the need for GCP

When it comes to mapping, accuracy is key. Traditionally, the use of ground control points has been a primary method of achieving bearing accuracy from drone mapping.

Ground Control Points – or GCPs as they are known – are marked points on the ground that have a known geographic location.

For aerial surveying and mapping applications, GCPs are typically required as they can improve the positioning and accuracy of mapping results. In fact, GCPs allow the survey drone to get fairly accurate data.

However, taking this approach has its drawbacks. This method can be labor intensive, requiring numerous checkpoints to be laid out and precisely geolocated, and can require a great deal of preparation. In some cases, more time is spent laying the GCPs than conducting the drone mapping itself.

There is a way to minimize or eliminate the need for GCP and that is by using RTK and PPK corrective technologies. And drones like the DJI Phantom 4 RTK and M30T benefit from this technology to streamline drone surveying missions.

Adopting this approach can eliminate, or certainly reduce, the number of GCPs needed. It has been estimated that RTK or PPK-enabled drone technology can save the 75% of time and money spent on mapping setup with drones and can produce accurate data in the center of the meter.

PPK V RTK – Who is the best for drone mapping missions

Drone pilots can take advantage of PPK (post-processed kinematics) and RTK (real-time kinematics) during surveying and mapping projects. But what's the difference?

RTK is a GPS correction technique that provides real-time corrections to location data when the survey drone is capturing photos of a site. Real-time correction is a major industry advantage.

PPK is another GPS correction technology technique that works to correct location data, except in the cloud after the drone data has been captured and uploaded.

In other words, this means that in terms of position correction, RTK does it during the flight, while PPK makes the adjustments afterwards.

RTK has many advantages, such as pinpoint accuracy of the aircraft during flight and accurate geotagging of information captured from the aircraft.

However, RTK requires a very specific base station and other equipment working together to process the data in real time and signals can be obstructed resulting in loss of correction data. This is not a problem with PPK.

PPK also removes the requirement for GCP saving additional field time.

Survey with and without RTK

Here is a breakdown of the benefits of using a drone with RTK, versus relying only on ground control points or flying a UAV without RTK.

Perhaps the best combination is to deploy a drone with RTK and a small number of strategically placed ground control points.

Having flown the DJI Phantom 4 RTK, Terra Drone Europe believes that in some cases the accuracy that can be achieved without GCP is less than 3-4cm, but when higher accuracy is needed, it is advisable to use a series of control points at land – but it is still a reduction compared to traditional surveying methods.

| GCPs Alone | Drone Without RTK | Drone With RTK | RTK Drone + GCPs | |

| accuracy | High | Low | High | Highest |

| Speed | Low | High | High | medium to high |

| Cost | High | Low | Low | Low |

BEST SOFTWARE SOLUTIONS

A guide to drone mapping software and drone fleet management platforms.

Sophisticated packages for mission efficiency and flight automation

Drone mapping and fleet management software are essential components of any successful UAV surveying program and our partners have partnered with some of the industry's leading vendors to equip surveyors with the tools to maximize their data and missions .

Each solution has its own set of features that can benefit the end user and business experts such as our partners can walk you through the ideal software package and help you unlock the license for your desired platform.

Drone mapping software

DJI Terra

DJI Terra transforms drone data into digital 3D models and maps to facilitate analysis and decision making.

Perform real-time mapping and generate high-quality 2D and 3D reconstructions and measurements, among other things.

An Electric Power license is also available, to provide new optimizations for power line modeling, helping business users create detailed 3D reconstructions of thin power lines.

Commercial Drone Operations – Simplified

DJI FlightHub - Manage your entire drone operation using DJI FlightHub, including the Enterprise Edition. If you're using multiple drones and pilots, while juggling multiple operations, DJI FlightHub will give you a complete, live picture of your entire drone program. Highlights include real-time communication with pilots during live operations; easy logging and flight log management; manage equipment, pilots and individual flights across the organization; and simple-to-use mission planning tools to increase efficiency.

DJI GS Pro - Enhance your drone operations with DJI Ground Station Pro (DJI GS Pro), an iPad app. GS Pro lets you conduct automated flight missions, manage flight data in the cloud, and collaborate across projects to efficiently execute your drone program. GS Pro lets you backup your flight data to the cloud; coordinate teams and designate roles for simplicity and clarity of mission; and generate efficient flight paths and load the collected data into reconstruction software to generate 3D maps.

DRONES FOR CONSTRUCTION

The best drones for construction.

Harness the power and versatility of DJI drones

As the world's leading drone manufacturer, DJI has a number of professional drones that are ideal for the construction industry.

The Phantom 4 RTK, for example, is a next-generation aerial mapping tool that can capture survey data and reduce the number of ground control points needed, helping to streamline missions.

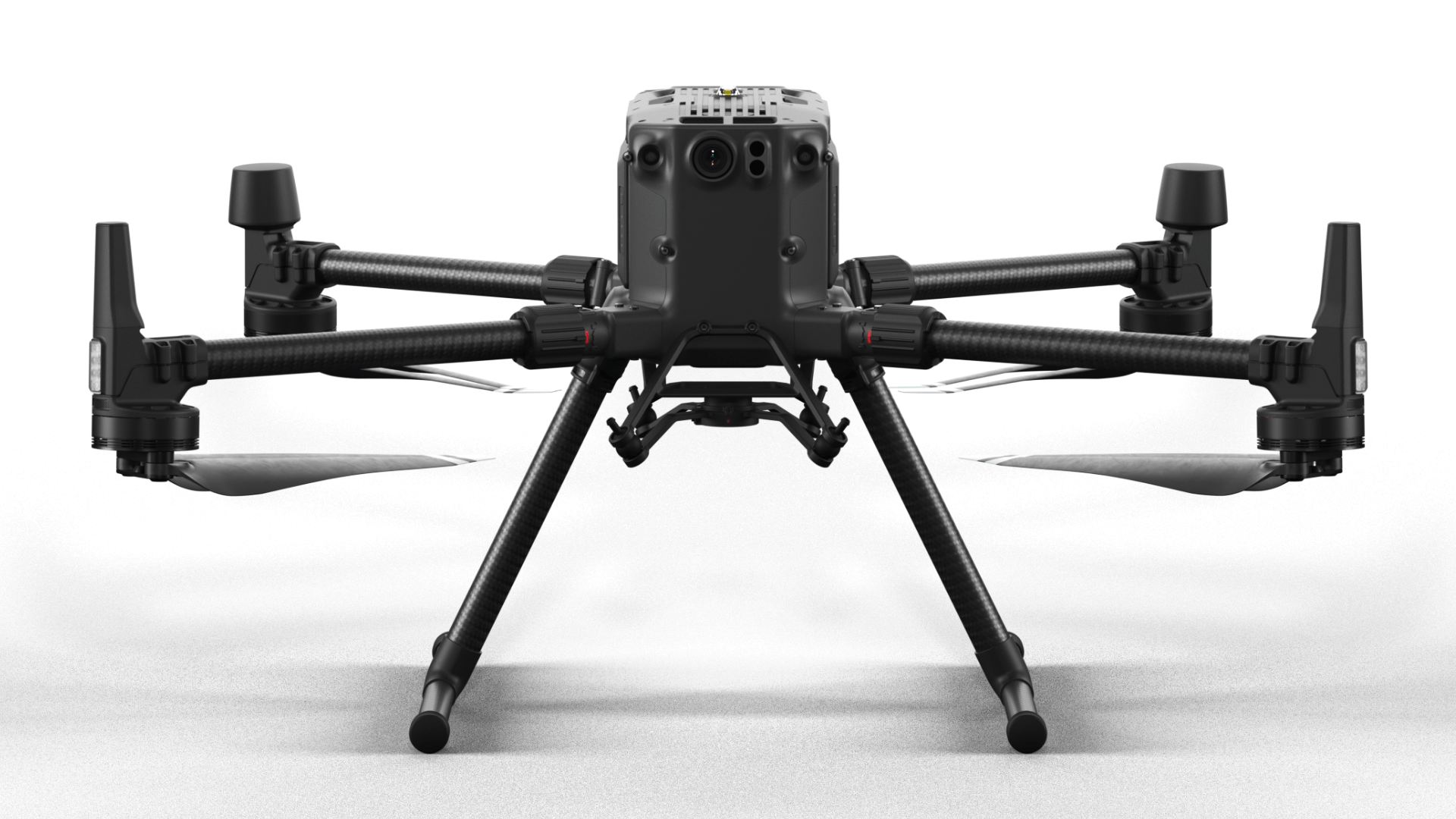

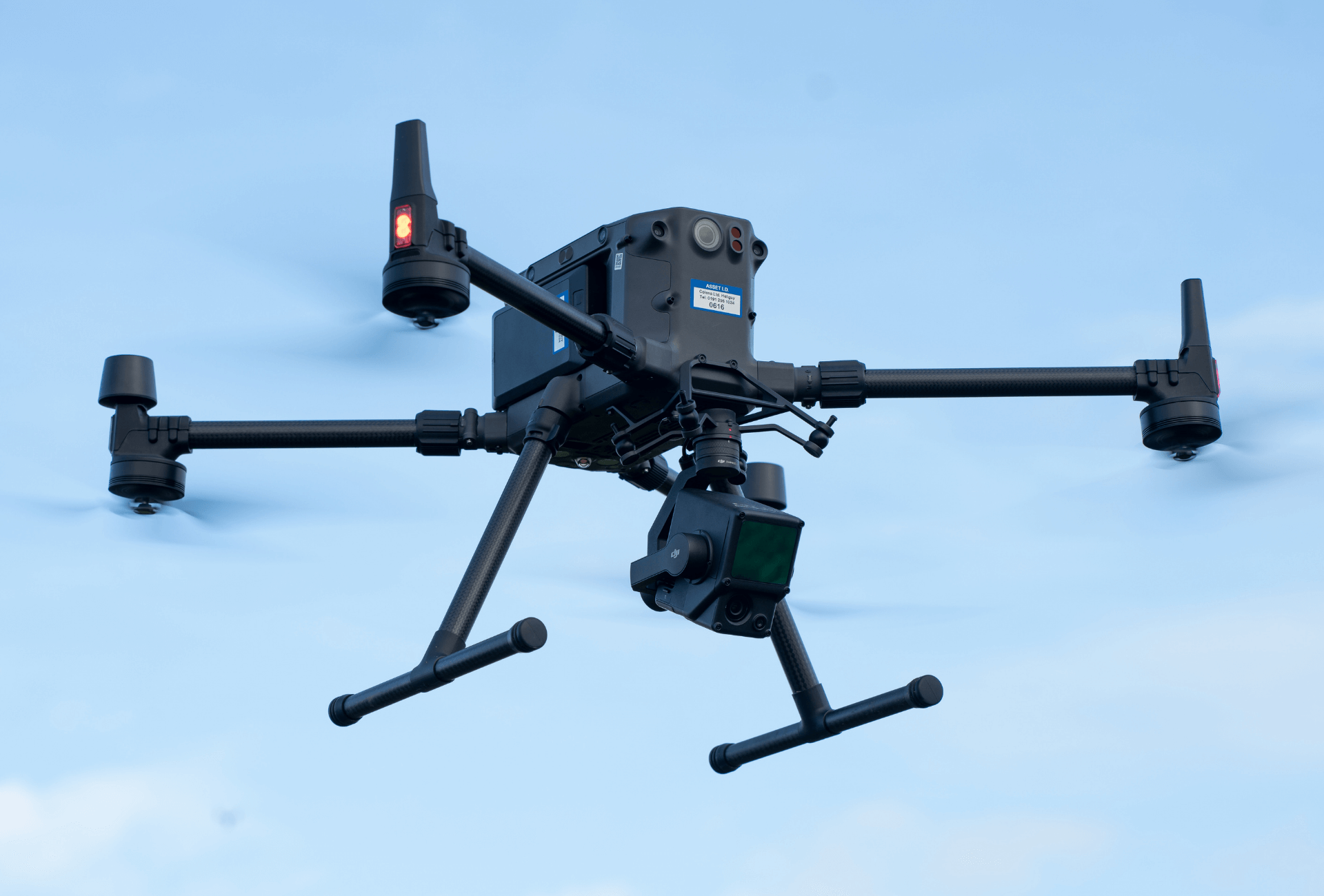

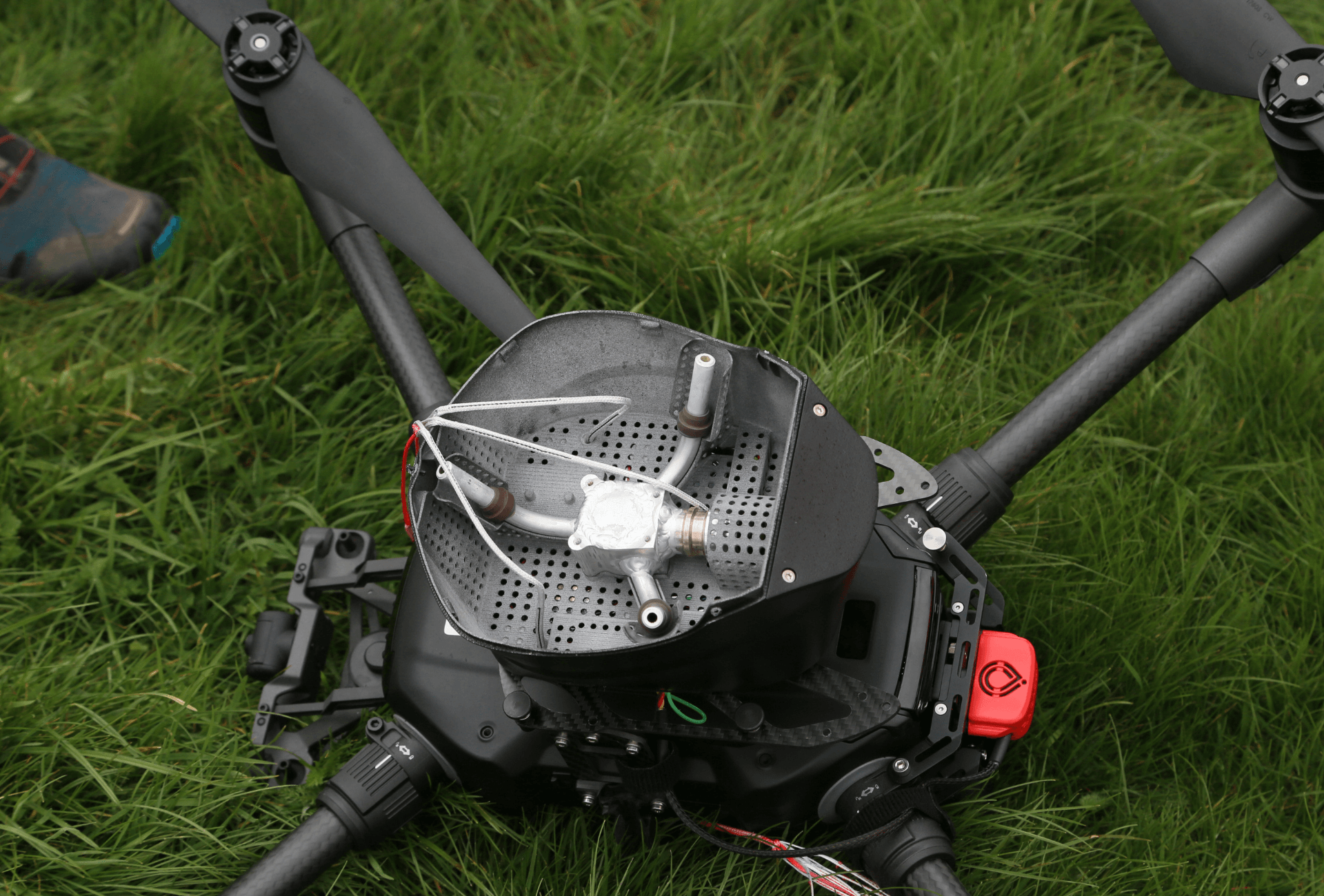

Other popular business tools include the Matrice range of drones, including the M300 RTK. All drones in the Matrice family are rugged, rugged commercial platforms that can be integrated with thermal, zoom, and vision cameras, as well as third-party sensors, such as LiDAR, oblique, or HazMat payloads, to increase mission versatility and efficiency. Matrice drones like the M300 are RTK-enabled.

To stay within the DJI ecosystem for surveying, the M300 RTK can be integrated with the DJI Zenmuse L1 sensor for LiDAR collection, while the 45MP DJI Zenmuse P1 sensor is a top-tier photogrammetry camera.

For a lower tier of construction drones, the Mavic 2 Enterprise Advanced Series are lightweight and rapidly deployable and are perfect for smaller budgets.

DJI drones, like the ones listed above, have enhanced flight safety features and obstacle avoidance features to increase safety when deployed in and around a construction site.

M300 RTK

- Up to 55 minutes of flight time;

- Carries up to three payloads simultaneously;

- Degree of protection IP45;

- Wide payload compatibility for inspections, such as H20T (including thermal, zoom, wide angle), L1 LiDAR sensor, P1 photogrammetry camera, and third-party payloads;

- Connect the CSM module to help detect small obstacles.

Mavic 2EA

- Radiometric thermal sensor 640 x 512 px;

- 48MP visual camera;

- 32x digital zoom and 16x thermal zoom;

RTK module available for CM-level positioning and increased flight stability, especially near power lines; - Create up to 240 waypoints for automated inspection;

- Complement it with extra accessories, such as a bright spotlight.

Phantom 4 RTK

- 1" CMOS sensor; 20MP; mechanical shutter to avoid blurring of the rolling shutter;

- Get RTK horizontal positioning accuracy of 1cm + 1ppm and RTK vertical positioning accuracy of 1.5cm + 1ppm;

- RTK module for CM-level real-time positioning data for absolute accuracy on image metadata. It also uses RTK for greater flight stability.

DRONES ON THE SITE – CASE STUDIES

How drones are benefiting construction.

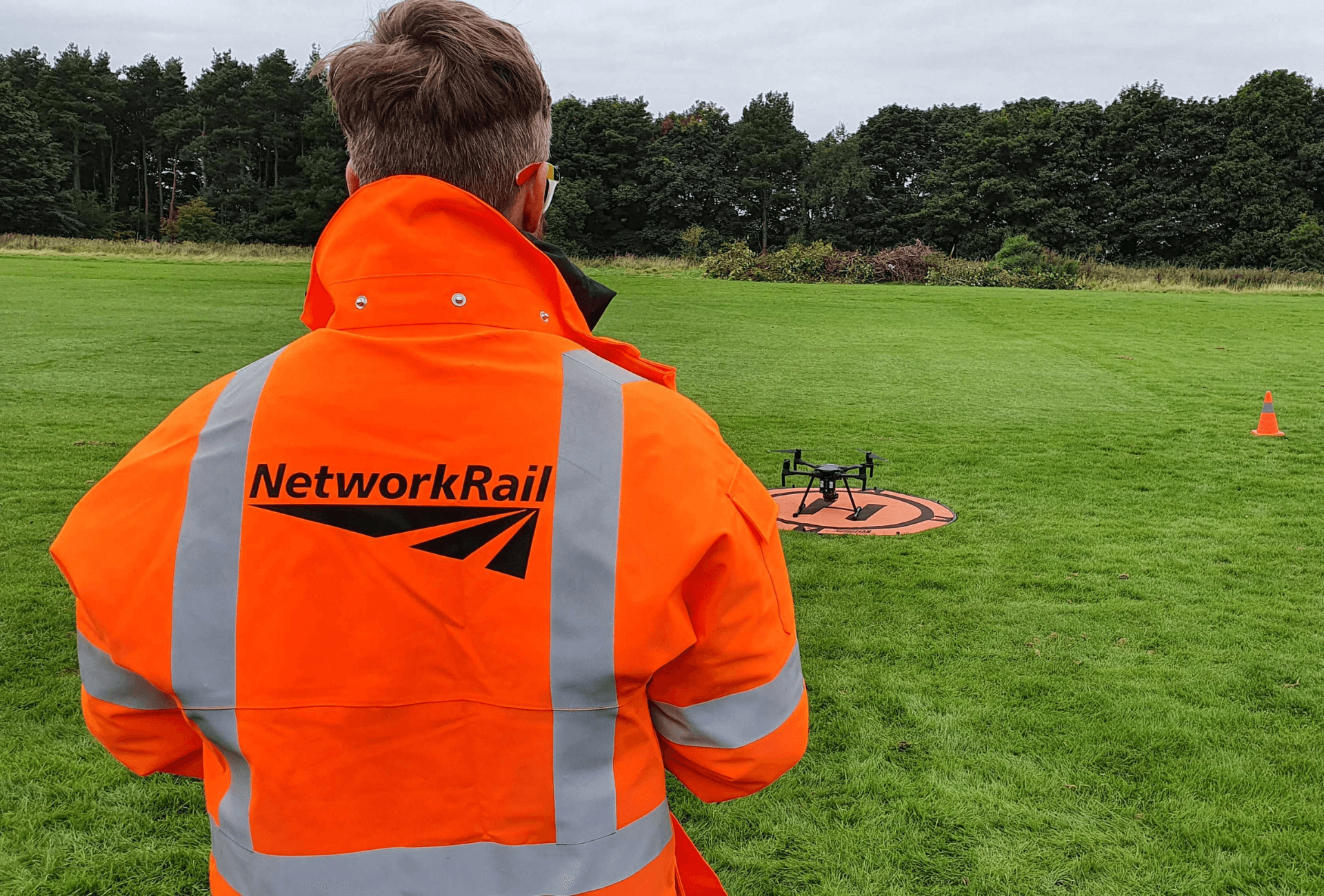

Balfour Beatty deploys drones on highway circuit

Balfour Beatty has used drones, including the DJI Phantom 4 RTK, during a €212m upgrade of the Smart motorway on the M6.

The international infrastructure group has used UAS for faster stockpile measurements, airborne progress reports and access to hard-to-reach areas.

The use of drones has helped the company improve safety, increase efficiency, collect data faster, improve resource productivity and achieve high-precision results.

Drones have proven their worth when it comes to measuring inventory volumes; they not only help with efficiency but also improve safety.

Drones = 75% cost savings for Chasco Constructors

Texas-based Chasco Constructors used drones to help manage construction on a major project at the Public Safety Training Center, in Round Rock, Texas. This included a 65,000 square foot main facility and 10 additional support buildings.

Using drone technology, the company was able to streamline workflow, complete the project ahead of schedule, and achieve cost savings of 75%.

Chasco Constructors has used drones to:

- Monitor work progress, including tracking subcontractors, tracking materials and equipment, and measuring inventory volumes;

- Capture and analyze site details far more detailed than a ground-based survey team could collect;

Enable surveyors to focus more on what they do best, such as high-precision layouts, bluetops, and utility cutsheets; - Collect regular aerial images to create high-resolution site maps and 3D models. Not only has this been useful for monitoring the progress of the site, but this data has enabled the Round Rock City Council to provide greater transparency to taxpayers about money well spent;

- It allowed managers to keep an eye on both their work teams and subcontractors;

- Identified a potential problem related to the excavation of a roadway. This eliminated mobilization costs that would otherwise have been required to complete further site work.

The drones have proved so useful to Chasco, the company is now using them to monitor more than 35 construction sites across Texas.

“Drones are very efficient tools for construction”

STRABAG is using the DJI Phantom 4 RTK in a construction project to widen Germany's A3 motorway near the city of Würzburg.

The team deployed drones to efficiently survey the site, allowing them to accurately plan and monitor progress.

The improvements are being implemented over several kilometers of motorway, on a complex terrain with steep slopes and numerous curves. The use of drones helps to reach these areas quickly and safely.

Thomas Gröninger, from STRABAG, says: “Drones are proving to be very efficient tools in the construction industry and I am convinced that they will be integrated more and more into construction processes on the international stage.”

The company has benefited from the DJI Phantom 4 RTK for numerous reasons. These include:

- Ground Control Point Reduction : Previously, the team had the time consuming task of setting up to 40 GCPs per square kilometre. Thanks to the Phantom 4 RTK, this is reduced to just 3-5 (or even zero in the same cases) per square kilometre, saving at least 75% in GCP setup time.

- More Efficient : With up to 30 minutes of flight time, the survey team used the Phantom 4 RTK to acquire a large amount of data in a single flight. The drone can also fly at a constant height over complex terrain for repeatable results.

- Multiple Insights : Thanks to data collected by the drone, the team was able to conduct volume calculations, build terrain models and monitor project progress. This means they can receive the necessary templates and information based on their project needs.

HOW 3DIGITAL CAN HELP YOU

Complete end-to-end support to grow your drone inspection business.

Your drone partner

A successful commercial drone program relies on a multifaceted approach. It's not just hardware; is developing a complete end-to-end workflow, with all components working effectively, together.

For that, you need a support pillar to help you build a solid foundation, cover all bases, and connect the dots.

This is where 3Digital in collaboration with its consulting partners can help you.

Our structure includes consultancy; hardware supply and support; logistics; industry-specific and pilot training; and repairs, incident resolution and research and development to provide an integrated and comprehensive support network.

Drone sales

- Free advice;

- Global network of industrial partners;

- Service Level Agreements;

- Delivery in a few days;

Drone courses

- Through our local partners we train and certify pilots;

- Courses approved by ENAC;

- On-site training and theory exams;

- Closed courses and sector-specific training;

Drone repair

- DJI-approved repair center, offering crash support and repair management;

- Warranty repairs/replacements, including access to the repair infrastructure in Italy from our Repair Centre;

- Firmware update and configuration support;

- Data analysis, customer support and resolution with the manufacturer;

- R&D lab for custom builds and sensor integration.

WHAT TRAINING IS REQUIRED FOR DRONE INSPECTIONS?

Get the qualifications you need.

Fly legally and safely

If you are planning to use a drone for inspection, it is important that you understand the rules and regulations and have the necessary training.

Our authorized partner ENAC's team of training experts can help drone pilots obtain the necessary clearances and meet the correct training criteria to enable them to deploy unmanned aircraft for inspection work.

3digital.tech

3digital.tech