3D Printer Filaments: Which One to Choose?

Source: 3dnatives.com

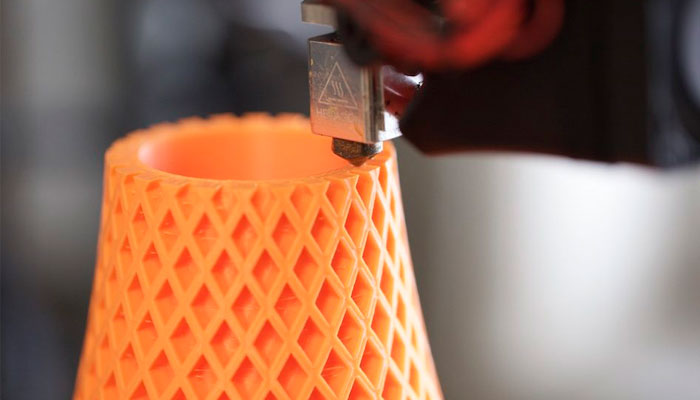

How to choose filaments for your 3D printer? What features should be considered? Fused deposition modeling (FDM) is one of the most popular 3D printing processes on the market due to its ease of use, accessibility, and performance. It is best known for being compatible with various thermoplastics, which are materials that soften under the effect of heat and return to their original shape when they cool. In order to be extruded by the 3D printer, these thermoplastics are transformed into a filament that can be guided and melted by the extruder. Today, most plastics in the industry can undergo this transformation, thus expanding the range of possibilities available.

Before moving on to the different 3D printer filaments that exist on the additive manufacturing market, it is important to understand how plastics are classified, a fundamental first step that will help you better understand the available materials and their characteristics. Today, there are the so-called amorphous or semi-crystalline plastics: these adjectives define the intermolecular structure of the polymer, depending on how they react when they solidify following fusion.

FDM is one of the most popular processes in 3D printing. It is compatible with plastic filaments.

In particular, chains of amorphous plastics become tangled and remain disordered during the solidification phase. Conversely, chains of semi-crystalline plastics organize and arrange themselves in relation to each other. This results in different properties: amorphous materials, for example, are usually more transparent and have lower dimensional stability. Finally, another important point that classifies the family of plastics is the melting temperature: standard plastics will have a lower temperature than so-called engineering materials. High-performance polymers, on the other hand, require more advanced thermal management, with melting temperatures around 300°C (572°F).

Standard filaments for 3D printers

The PLA

PLA, or polylactic acid, is a semi-crystalline material derived from renewable sources, usually corn starch. Unlike most plastics derived from the petroleum industry, PLA is considered more environmentally friendly because, under the right conditions, it is biodegradable. It is a very easy to use 3D printer filament, which is why it is very popular on the 3D printing market. Compatible with food products, its extrusion temperature is usually 180 ° C. It has good geometric stability and is usually not subject to deformation. It is mainly used for prototyping, machining, decorative parts or in the medical sector. PLA is available in a number of colors and is often used as a matrix for composite materials.

Polypropylene

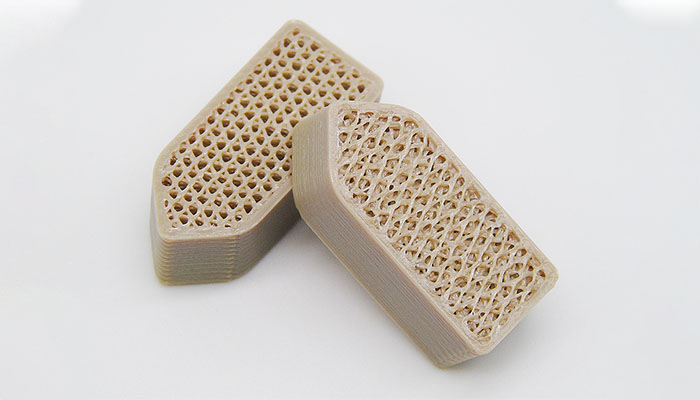

PP is one of the most widely used materials in injection molding, known for its light weight, chemical and fatigue resistance, and good electrical insulation. It is also available as a filament for 3D printers, and offers good impact resistance, good gas sealing, and semi-rigidity. It should be noted, however, that it is quite difficult to print, as it does not adhere to the plate. It has very precise melting points and requires excellent thermal management. In terms of applications, PP filament is used for packaging, clips and fasteners, liquid containers, etc.

A 3D printed piece made of PP (photo credits: Materialise)

ABS: One of the Most Used 3D Printer Filaments

This time we move on to an amorphous structure: ABS is a filament known for its low-temperature impact resistance and its lightness. It is not always easy to classify this material: it is sometimes found in the technical part of the pyramid and is less easy to work with than PLA, for example. In 3D printing, it is subject to deformation, which is why it requires the use of a heating plate. Its properties make it the ideal material for the production of functional prototypes, frequently stressed tool parts or mold manufacturing. ABS is one of the cheapest 3D printer filaments and therefore among the most used.

Technical filaments

Nylon

Nylon, also known as polyamide (PA) is present on the additive manufacturing market mainly in the form of powder for SLS technology. However, it can be found in the form of filaments, available with 6 carbon atoms, so PA6. The latter is similar to ABS and also requires a heated bed because it does not adhere optimally. PA6 is known for its resistance to impacts and abrasion, as well as its flexibility. It has a fairly long lifespan, ideal for the production of parts such as hinges, machine components and tools. It can be reinforced with carbon or glass fibers. It should be noted that nylon is a material that absorbs moisture, so it is important to store it in a dry place.

Humidity control is essential for PA6 (photo credits: Sharebot)

PET, a more technical filament for 3D printers

PET is a very well-known material as it is used to produce plastic bottles. In 3D printing it is better known as PETG, i.e. with the addition of glycol to reduce its brittle appearance. It is mainly known for its transparency and its food compatibility. For example, many packaging and containers are printed with PETG. It is a good alternative to PLA or ABS.

The POM

Polyoxymethylene, or POM, is a semi-crystalline material that is becoming increasingly used in 3D printing. It has excellent chemical properties, is resistant to heat, impact and abrasion. POM can be used in 3D printing for various applications, such as backpack buckles, components that need to be exposed to heat or gears. However, it is a rather difficult filament to print because it requires good thermal management – bed, extruder and chamber. It should also be noted that there are few manufacturers of this type of 3D printer filament compared to materials such as PLA or ABS.

POM is becoming more and more common in 3D printing (photo credits: POM)

Polycarbonate, an amorphous filament for 3D printers

Polycarbonate (PC) is used primarily for its strength and clarity. It is not an easy thermoplastic to print because it requires higher extrusion temperatures and a heating plate. It is especially popular in the optical industry because it is less dense than glass and can withstand temperatures ranging from -150 to 140°C (-238°F to 284°F). Typically, protective screens and optical parts can be 3D printed with polycarbonate. This 3D printer filament is becoming increasingly common in the product range offered by manufacturers in the industry.

High performance thermoplastics

This last category of polymers is known to be more demanding: the thermoplastics contained in it require high melting temperatures and have characteristics that are close to those of some metals. In additive manufacturing these filaments will require a high extrusion temperature, a heated bed and a closed chamber. Thermal management is essential for this type of material.

Some thermoplastics require excellent thermal management (photo credit: 3DGence)

The semi-crystalline

PEEK is probably the most common 3D printer filament in this category. It belongs to the PAEK family and requires an extrusion temperature of around 400°C (752°F), a build plate capable of reaching 230°C (446°F), and a heat chamber at 120°C (248°F). PEEK is known for its strength-to-weight ratio and can withstand high temperatures. It can be sterilized, making it the preferred material for printing custom implants. It is a fairly expensive 3D printer filament and also requires some mastery of the 3D printing process.

PPS is also a high-performance semi-crystalline material, known for its chemical resistance and mechanical properties. It is mainly used in the automotive, oil and gas, and electronics industries. Its extrusion temperature is around 300°C (572°F); it also requires a heated bed and a closed chamber.

PEEK is often used to 3D print custom implants (photo credit: FossiLabs)

High Temperature Amorphous Filaments

In this category we can first mention PEI, a 3D printer filament now marketed by SABIC under the ULTEM brand. Less expensive than PEEK, it meets fire/smoke standards, making it the ideal material for the aerospace industry. PEI is also resistant to fluids, hydrocarbons, alcohols and aqueous solutions in the automotive field. It can be sterilized and is compatible with food contact.

Finally, we cannot forget the sulfone family, especially PPSU and PSU. These are very interesting thermoplastics in terms of thermal properties and fire/smoke characteristics. They also have good electrical insulation and good dielectric properties. They are popular materials in the transportation sector, including railways, aerospace and automotive.

Composite and flexible filaments for 3D printers

Finally, it is important to mention composite filaments and elastic materials. Composite materials are materials formed by a matrix (PLA, nylon, polycarbonate, etc.) and reinforced by fibers, most often carbon. Glass, aramid, etc. can also be used. This increases the strength of the filament while optimizing its weight.

Finally, flexible 3d printer filaments such as TPU are part of the FDM materials offering. These are materials known for their resistance to wear and impact. They are particularly interesting in the production of orthopedic calipers or insoles; however, they are sensitive to high temperatures.

TPU is a flexible material

https://3digital.tech

https://3digital.tech