Power Generation Management - DJI ENTERPRISE

Main benefits of power generation management

Inspection of the boiler

Send drones in place of inspection personnel in the boiler for a complete and automated internal inspection without interrupting functions, keeping inspectors safe.

Wind turbine inspection

Perform automated flights on and around wind turbines to document their condition and magnify defects for timely repairs.

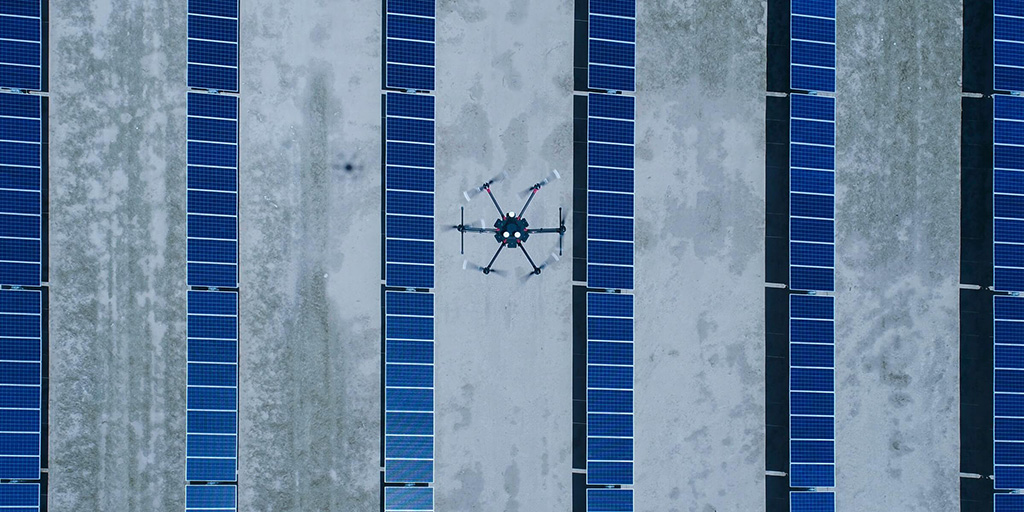

Inspection of the solar photovoltaic system

Get real-time temperature readings of solar panels using drones equipped with visual and radiometric thermal sensors to immediately identify anomalies.

Inspection of the boiler

Traditional challenges in boiler inspection

- An inspection platform or scaffolding is required to access and inspect the boilers, which poses risks to personnel safety and costs time and money.

- Inspection reports performed by different team members are not consolidated or even digitized, making it difficult to record data.

How drones inspect boilers

- The drones are compact and flexible, capable of flying into boilers for a full scan without shutdowns or endangering inspectors. Live footage helps identify risks for informed decision making.

- DJI drones feature advanced obstacle detection systems with the ability to add a reflector mount, so they can be reliably used for interior inspections.

Wind turbine inspection

Traditional challenges in wind turbine inspection

- Operations must be suspended for inspections, where cranes lift personnel high to get closer to the blades and record observation data, which is risky and time-consuming.

- Inspection data is qualitative records that may not be digitized, which can cause record-keeping problems and take longer from inspection to repair.

How drones inspect wind turbines

- Automated flight routes can be set up to conduct accurate and repeatable inspections of the wind turbine without risk to personnel safety.

- Drones can get close-up images of blade defects such as cracks, water infiltration, corrosion or rust with a zoom camera without interrupting operations.

- The results of the drone inspection are quantitative and digitized, facilitating data analysis and registration.

Inspection of the solar photovoltaic system

Traditional challenges in inspecting the solar photovoltaic system

- Inspecting solar panels from the ground can be slow and incomprehensible due to the limitations of perspective and portable devices.

- Inspection data is qualitative records that may not be digitized, which can cause record-keeping problems and take longer from inspection to repair.

How drones inspect solar photovoltaic systems

- Automated flight routes can be set up to conduct in-depth and repeatable inspections of solar farms without risk to personnel safety.

- The drones allow teams to view temperature readings and visible light footage in real time so that any hot spots on PV components can be identified immediately.

- Drone inspection data is digitized and ready for further analysis or recording, significantly improving efficiency.

https://www.instagram.com/3digital.tech/

https://www.instagram.com/3digital.tech/