SLA vs. DLP: Which Resin-Based 3D Printing Technology Should You Choose?

Source: 3dnatives.com

SLA and DPL 3D printing technologies are known to be based on the use of resin as a printing material. Let's first give an overview of the two technologies, and then discover their specific characteristics and differences. From the invention of the stereolithography (SLA) in 1984 by Charles Hull, several technologies have emerged such as FDM, SLS and MJF. Some are even derived from SLA such as Digital Light Processing (DLP). Today we will focus on SLA and DLP technologies and compare them: while the two technologies have many similarities, there are some obvious differences. How do these technologies work? What materials can be used? Who are the main manufacturers? We will explain!

SLA vs DLP Technologies

SLA and DLP 3D printing technologies have many differences and many similarities. Both expose liquid photopolymers to a light source, use resin, and are suitable for printing small models with fine details. The methods are compatible with flexible or hard materials and can also print composites, filled with glass or ceramics, for example. It should be noted that the printed parts are relatively fragile and at risk of deterioration if exposed to the sun and may be subject to warping.

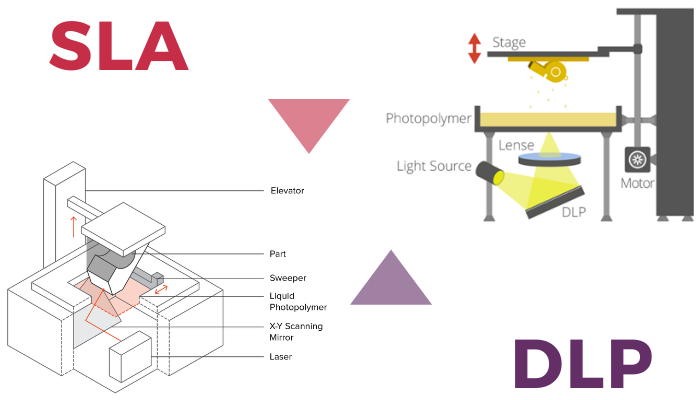

The first 3D printing technology developed in 1984, stereolithography, is now considered one of the most accurate 3D printing processes on the market. Unlike DLP technology, the light source used is a laser. The laser beam passes through the resin tank along the horizontal axis and solidifies the material layer by layer. Today, there are two types of machines: those where the laser acts from top to bottom, with a plate that descends with each new layer, and those where the laser acts from bottom to top, with a plate that gradually rises. SLA produces smooth surfaces and a layer thickness of between 0.05 and 0.01 mm, allowing the printing of objects with extremely thin layers.

Coming from an image projection technology (dating back to the 1980s), the Digital Light Processing method uses a projector as a light source. This way, a single projection of light hits the entire resin bed. At the heart of this process is the digital micromirror device (DMD), placed between the projector and the resin. It is made up of several individually controlled and activated microscopic mirrors: if they are active, they reflect the light back to the resin and cure it. They then produce a type of mask that cures the resin according to the desired pattern. Some 3D printers have now replaced this DMD with an LCD screen, dramatically reducing the price of the machine.

SLA and DLP printing process diagrams (photo credits: 3D Hubs / bitfab)

The DLP process is considered faster than stereolithography because it does not work dot by dot. Also, due to their projectors, DLP printers are larger and most of the time, the resin tank of DLP machines is shallower than that used in the SLA process.

Finally, the last difference between SLA and DLP technologies is maintenance. DLP printers require little maintenance and are often easier to repair – the presence of the laser in SLA machines greatly affects this aspect.

Print quality

Print quality is often a decisive factor when choosing between two technologies. This is especially true if 3D printing is to be used for the production of finished parts, which means that the level of detail, structure and surface play a very important role. In principle, it can be said that both technologies make it possible to design precise, high-resolution models with a very fine level of detail. However, it is not only the process itself that is decisive for the quality of the print, but also the choice of material, which often depends on the manufacturer.

When printing with SLA technology, the resin is cured point by point on the print bed. The longer the part, the longer the printing time will be, as the laser must pass along the entire bed. SLA is therefore best suited to printing objects with a length between a few millimeters and 1.5 meters. However, there is no loss of quality due to length and a Z resolution of up to 25 microns is possible: both are independent of the size of the model.

DLP technology allows for layer thicknesses of up to 5 microns. However, it is important to note that DLP 3D printers can create a “staircase” effect on the final product due to the projection of pixels, which negatively affects the final surface of the printed parts. When printing long components, quality loss can occur at the sides. In fact, the center of the plate receives the greatest concentration of energy from the projector; the light is then gradually diffused to the edges.

Technical features

Printing speed

In terms of printing speed, DLP technology is definitely ahead. In fact, since DLP cures an entire layer of resin at once, the printing process is much faster. Unlike the SLA process, where the resin is cured point by point, in the DLP process only the height of the component affects the printing speed.

Print volume

Stereolithography is not used to produce large parts due to the high cost of materials compared to other processes, such as FDM. In addition, the print volume is limited to the size of the tank that contains the liquid resin.

The build volume of the Formlabs 3L SLA printers is 335 x 200 x 300 mm and it is 1500 x 750 x 550 mm for the 3D Systems Pro X 950. As for DLP printers, the build volume of the Envison TEC Xtrem 8K is 450 x 371 x 399 mm and it is 400 x 330 x 500 mm for the Carima DM400A model.

The Form 3L model has a larger build volume (photo credit: Formlabs)

Post-processing

In all resin 3D printing processes, post-processing of the parts is mandatory. This is because very thin models require support structures, which need to be removed after curing. This step can be time-consuming and is probably one of the main disadvantages of resin 3D printing. The differences in post-processing are mainly related to the material used, whether in the SLA or DLP process. In addition to cleaning the parts from liquid resin with isopropyl alcohol (IPA) or tripropylene glycol monomethyl ether (TPM), drying, removal of support structures, possible post-curing and, if necessary, sandblasting and painting of the parts must also be taken into account.

In principle, it can be said that post-processing in SLA and DLP processes is not only time-consuming, but also requires a certain level of experience on the part of the user or should be left to specialists. Post-processing in 3D printing is often a problem for customers; that is why some companies have already specialized in optimizing or automating this step.

Removing the print support is a post-processing step that can take time.

Application cases

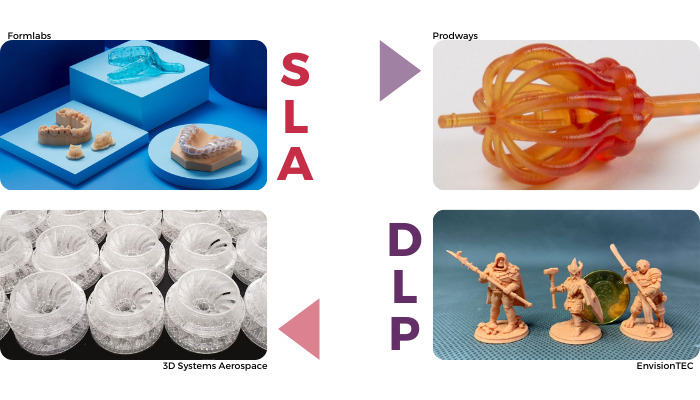

In terms of application cases, SLA and DLP technologies are largely used in similar industries. In particular, the jewelry and dental industries regularly use resin 3D printing. For example, the manufacturer Formlabs offers various resins specifically for healthcare professionals. Numerous companies use them to create different types of medical devices. However, due to the wide variety of materials available, many other industries also use resin 3D printing. There are resins suitable for different applications: prototyping, injection molding, or engineering.

SLA and DLP: Accuracy is remarkable in both technologies

Main producers

Currently, some 3D printer manufacturers have switched to SLA technology. Of course, one of the leading manufacturers remains 3D Systems, the company founded by Charles Hull, but over time other manufacturers have emerged. This is the case, in particular, of Formlabs, which has established itself as one of the leading companies in the field of SLA 3D printers. In addition to providing SLA machines, the American company offers numerous resins and other materials, such as the Castable Wax 40 resin for the dental sector. With its range of XFAB printers, the manufacturer DWS also offers machines based on stereolithography.

When it comes to DLP 3D printers, EnvisionTEC, founded in 2002, is considered a pioneer in the sector. Like B9 Creator and Asiga, many companies have taken advantage of DLP technology to develop their printers. We can also mention manufacturers who have relied on DLP technology to create a faster one, such as Carbon 3D with Digital Light Synthesis (DLS) that can control the flow of oxygen or Photocentric and Daylight Polymer Printing (DPP). Finally, the French company Prodways has also patented a process similar to DLP: MOVINGLight technology.

EnvisionTEC is considered the pioneer of the DLP process in 3D printing (photo credits: EnvisionTEC)

SLA and DLP 3D printers price

In most cases, DLP printers are less expensive than SLA printers. But as with all 3D printer ranges, it is important to differentiate between desktop and industrial 3D printers.

As far as entry-level SLA printers go, the most affordable machine is the Form 2 from Formlabs. With a build volume of 145 x 145 x 175 cm, the Form 2 boasts a laser point accuracy of around 145 microns. Available starting at $2,400, the machine has been on the market since 2015. It should be noted, however, that the American manufacturer has since developed the Form 3 and Form 3L models.

On average, the price of a SLA 3D printer ranges between $3,000 and $4,000. However, if you are looking for an industrial machine, prices increase exponentially. For example, 3D Systems' industrial SLA solutions are marketed at prices that hover around $500,000. It should also be noted that printers equipped with a laser that works from top to bottom are generally more expensive.

Much more affordable, DLP 3D printers appeal to many additive manufacturing enthusiasts. Anycubic sells several DLP machines priced around $200, such as the Photon Zero printer. Professional machines, including those offered by EnvisionTEC for the dental and jewelry industries, are available for around $15,000. As always, prices can vary depending on the manufacturer. The manufacturer Asiga also offers professional DLP 3D printers, but at a price of around $1,000.

SLA vs DLP. Specifications are for a desktop 3D printer.

3digital.tech

3digital.tech