Is PLA really biodegradable?

Source: 3dnatives.com

The PLA is the 3D printing material most popular and widely used for the FDM printers. One of the main reasons is that, compared to other materials, it is a very easy plastic to print. This makes it the ideal filament even for the less experienced. It is also said that PLA filaments are more sustainable because PLA is biodegradable. But is this really the case? How sustainable is PLA really? To find an answer to our questions, we spoke to some experts and asked their opinion on the matter.

Here are our experts: Florent Port, President of Francofil, a French company that develops and produces large quantities of filaments for 3D printing in Normandy; Nicolas Roux, CEO of the company Zimple 3D that offers solutions to simplify the use of 3D printers (air filtration systems, for example); Jan-Peter Willie, co-founder of 3D4Makers, a Dutch company that produces filaments with many years of experience in plastic production.

The purpose of the interviews with our experts was to define lies and truths about the PLA. The Is PLA Really Sustainable ? To learn more about this material, we focused on its biodegradability, emissions, production, and other issues such as recyclability.

How is PLA produced?

The PLA, also known as polylactic acid or polylactide, is made from renewable and natural raw materials such as corn. Starch (glucose) is extracted from plants and converted into dextrose by adding enzymes. This is fermented by microorganisms into lactic acid, which is then converted into polylactide. Polymerization produces long molecular sequences whose properties resemble those of petroleum-based polymers.

Pure PLA is produced from renewable raw materials and is not based on fossil raw materials, like ABS. This is very positive when you consider that crude oil is a finite resource. However, an ethical question arises: is it justifiable to produce plastic from food, when the world population is ever growing and more food is required? Jan-Peter Willie comments, “ There is a lot of debate about the total consumption of carbon, fossil fuels and water in the production of bioplastics from natural materials and whether or not they have a negative impact on the human food supply. To produce 1kg of PLA, the most common commercially available plastic, 2.65kg of corn is needed. As 270 million tonnes of plastic are produced every year, replacing traditional plastic with corn-based PLA would remove 715.5 million tonnes from the food supply, at a time when global warming is reducing the productivity of tropical farms .” In other words, if we switch to bioplastics, the food fields will have to compete with the plastic fields.

PLA: What do the terms biodegradable and compostable mean?

The terms “biodegradable” and “compostable” and their differences are of fundamental importance and are often misunderstood. Jan-Peter Willie explains, “ Many people confuse ‘biodegradable’ with ‘compostable’. In a broad sense, ‘biodegradable’ means that an object can be broken down biologically, while ‘compostable’ typically specifies that this process will result in compost .” A “biodegradable” material can be broken down under certain anaerobic or aerobic conditions. However, almost any material will decompose over time in nature. Therefore, the precise environmental conditions for biodegradability must be explicitly defined.

Composting, on the other hand, is a man-made process. According to the European standard EN13432, a polymer or packaging is considered “compostable” if within 6 months in an industrial composting plant at least 90% of it is converted into carbon emissions by microorganisms and additives present in a maximum percentage equal to 1% of the initial mass and are harmless. Or, to summarize, we could say that “all composting is always biodegradation, but not all biodegradation is composting”.

Can PLA filament be called biodegradable?

In advertisements or descriptions of PLA, we often read “biodegradable PLA”, which suggests that PLA, just like kitchen waste, can be decomposed in home compost or in nature. However, this is not exactly the case. PLA can be called biodegradable, but “ under the specific conditions of industrial composting; it is more appropriate to say, in this case, that it is a biodegradable polymer. For PLA to be truly degradable, industrial composting conditions are needed, i.e. controlled temperature and humidity in the presence of microorganisms”, explains Florent Port. Jan-Peter Willie adds , “PLA is compostable but only in an industrial composting plant .”

In these industrial composting conditions, PLA can be biologically degraded in a few days, at most in a few months. Temperatures must be above 55-70°C. Nicolas also confirms: “ PLA can be biologically degraded in industrial composting conditions ”.

Organic waste processing

Unfortunately, the definition of biodegradable PLA used by manufacturers and distributors can mislead the end consumer if it is not explained well. The Federal Environment Agency (federal agency for the environment) points out in its report that a greater environmental impact due to micro-plastics can occur if PLA is thrown into the environment due to this alleged biodegradability communicated.

In the environment, PLA takes at least 80 years to decompose, which means that in the sea and on land it contributes to environmental pollution due to plastics and, above all, microplastics. For this reason, PLA should not be thrown into the environment, in home composters or among organic waste, just like any other type of plastic.

Can PLA and other bioplastics be degraded in all composting facilities?

The answer is no. A survey conducted by the German Environmental Aid (DUH), which includes almost 1,000 German composting plants for organic waste and biowaste, has shown that 95 percent of these composting plants are not able to compost bioplastics according to standards. In addition, 80 percent of these composting plants that process German organic waste and biowaste consider bioplastics to be an interfering substance. This shows that although PLA can in theory be biologically degraded, in practice the corresponding infrastructure for the degradation of PLA and other bioplastics is lacking.

Can PLA be recycled?

According to our three experts, PLA can be recycled. However, Florent Port points out, “ There is currently no official collection of PLA waste from 3D printing. Indeed, the current channels for plastic waste make it difficult to distinguish PLA from other polymers such as PET (water bottles), and contamination of these materials with PLA negatively impacts recycling. Technically, PLA is recyclable as long as the collection only involves PLA, without any contamination from other plastics .”

What should we know about emissions from 3D printing with PLA?

Many people mistakenly believe that emissions from printing PLA are completely harmless because PLA, when printed, emits a rather sweet smell. Petroleum-based ABS, on the other hand, emits an unpleasant plastic smell. Nicolas Roux, CEO of Zimple 3D, is an expert on filament emissions and we asked him about it. He told us: “ Scientific studies have shown that PLA emits a significant amount of nanoparticles that can cross the alveolar capillary barrier and contaminate the entire body via the blood .” This barrier or membrane is the part of the lung through which gases exchange functions, namely the absorption of oxygen and the emission of carbon dioxide.

“ These particles are mainly lactide, but other toxic particles can also be released as the filaments used are rarely 100% PLA and contain up to 40% additives. This is why tests show that PLA emits styrene, chloromethyl and numerous other carcinogenic compounds known to be present in the chemical industry.” A report from the Federal Environmental Agency also confirms exposure to particulate matter, nanoparticles and VOCs (volatile organic compounds) in extrusion 3D printing of PLA and other plastics such as ABS, with ABS emissions being higher than PLA.

A filter can be used to protect against PLA emissions while printing

How dangerous are these emissions?

“ In the absence of a compliant safety data sheet, the risks vary greatly from filament to filament, even though they are present in all of them. The additives used and the manufacturing process of the filament have a significant impact on the dangerousness of the emissions ,” explains Nicolas Roux. It is therefore certain that when printing PLA, nanoparticles can escape uncontrollably into the air and contaminate the user’s body. “ That’s why it is necessary to protect yourself by limiting the risk .” Nicolas Roux recommends never working near a 3D printer in operation, ventilating the room where printing is done and, if necessary, using a filtering system.

Are some filaments more eco-friendly than others? What are the alternatives to PLA?

Florent Port explains, “ Organic filaments are more environmentally friendly than those made from fossil resources .” Additives are very important here. Some manufacturers like Francofil even produce PLA filaments that do not contain any chemical additives. Many of their PLA filaments have by-products (waste) such as mussels, wheat, and coffee grounds added, making them 100% bio-based.

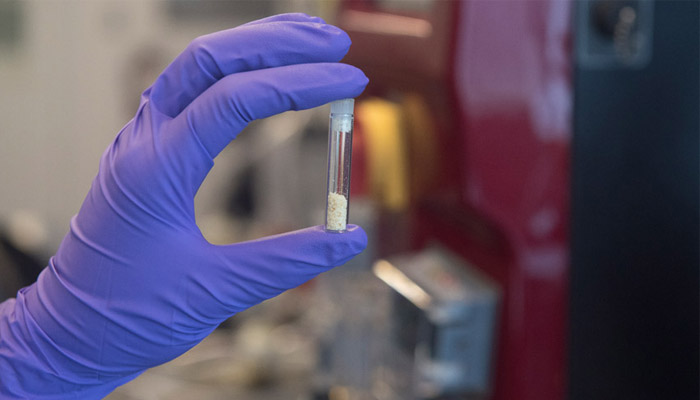

PLA filament with bio-based additives

Nicolas Roux believes that there are no truly sustainable alternatives to PLA filaments: “ Unfortunately, I do not know of any truly ecological and safe filaments that do not emit particles or that are able to biodegrade on their own in the soil or in the sea. In my opinion, the preference for filaments with compliant safety data sheets by European manufacturers is a responsible attitude when choosing materials .” Jan-Peter also recommends European filaments: “ For PLA from Asia, there are many suppliers who do not specify what their filaments contain .”

He continues: “ There are a lot of plastics that are made from natural raw materials, but it’s rare to see them as filaments. It’s probably difficult to make filament out of them, or they’re not suitable for printing .” However, there are companies like Canadian startup Genecies that are working on developing polymers that can degrade in natural environments after about 12 months. Some manufacturers like Nefilatek are also now offering recycled filaments. This is still plastic, but it’s definitely more sustainable than a new material.

Genecis PHA plastic in its granular form before being refined and transformed into pellets

PLA is therefore biodegradable only if treated in industrial composting plants. However, due to the lack of infrastructure, it is difficult to compost PLA industrially or recycle it. Contrary to popular belief, PLA also emits substances harmful to health, but in smaller quantities than, for example, ABS. So the real problem with PLA filaments is that their properties are sometimes communicated incorrectly and not clearly defined; in some cases there may even be false environmentalism.

Overall, it can be said that PLA is in some ways more sustainable than plastic derived from fossil fuels due to its production from renewable raw materials and the possibility of biodegradation. But it is and remains plastic that pollutes nature and the seas and it is therefore important, as in the case of all the plastic you use, to recycle it.

Using only what you really need is the best alternative.

3digital.tech

3digital.tech