PLA FILAMENTS: EVERYTHING YOU NEED TO KNOW

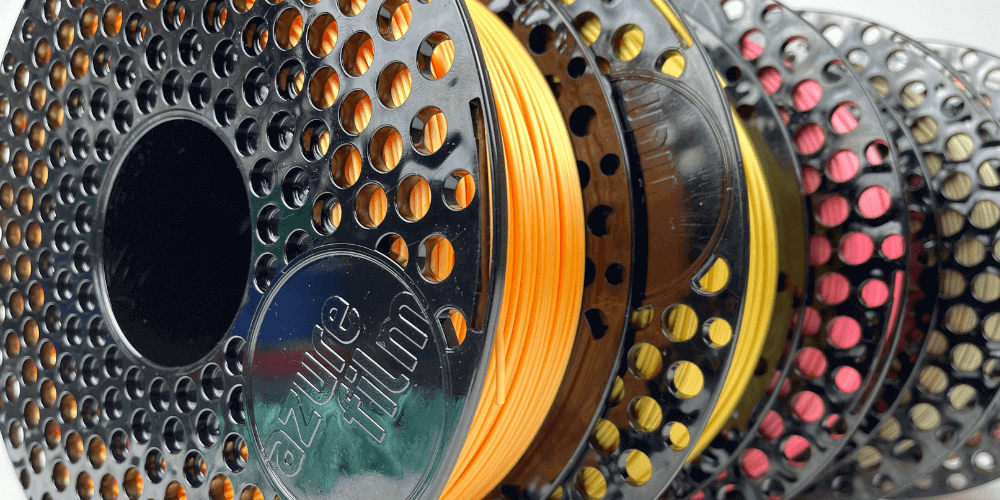

PLA is one of the most widely used 3D printer filaments, renowned for its wide color gamut, versatility and style. Precisely for this reason it is suitable for various printing applications. Those who want to create high-quality, vibrant and beautiful 3D prints often use i PLA filaments .

PLA (Polylactic Acid) filaments are very easy to use and perfect for beginners to do experiments. But what makes them one of the best filaments for 3D printing?

In this article we have reported everything you need to know about this fantastic filament. A better knowledge of filaments stimulates your creativity to exploit your potential.

What are PLA filaments?

PLA is an eco-friendly 3D printing filament made from organic raw materials. The raw material used is corn and sugar cane starch. The production process of this thermoplastic monomer is what sets it apart from other 3D printing filaments.

Manufacturers use biomass resources to produce PLA filaments. The same equipment used to produce petrochemical plastics can be used to produce PLA filaments. From this point of view, the difference between the raw products does not matter. Furthermore, production costs do not increase, which is a nice plus.

PLA is environmentally friendly as it is biodegradable , requires 65% less energy than the production of traditional plastics and can be welded using solvent. Furthermore, it contains no toxins and produces 68% fewer greenhouse gases.

How Are PLA Filaments Produced?

Fermented starch from plants such as corn, sugar cane or cassava is used to produce PLA filaments. The fermentation of raw materials transforms them into lactic acid which in turn produces PLA. Manufacturers usually use two methods to produce PLA filament.

- Polymerization

- Condensation

With the polymerization method , metal catalysts are required. To obtain large PLA molecules, it is necessary to mix lactide with metal catalysts. The condensation method It doesn't differ much from polymerization. The byproducts and temperature are slightly different from the first method.

Different blends of PLA filaments can also be produced by combining materials such as copper, bamboo, pine, cedar, bronze, carbon fiber and others.

The combination of wood and PLA filaments makes 3D printed furniture more realistic. If you want to give your printed parts a shiny look, combine metal with PLA. By doing so, the print will also become more resistant.

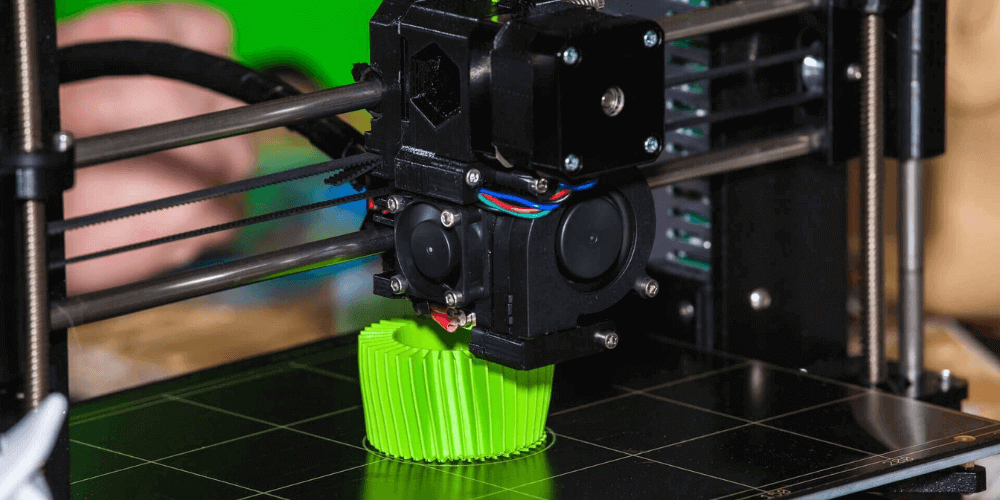

How to Print PLA Filaments

The Creality Ender, FlashForge and Artillery are some of the 3D printers more compatible with PLA materials. However, there are some things you need to keep in mind when printing with PLA filaments:

Temperature

To ensure optimal printing, it is necessary to take into account the temperature of the tip and the nozzle rather than the temperature of the print bed. When the temperature is high, the adhesion between the layers of the print becomes optimal. High temperature means faster printing and better material flow.

However, too high a temperature can affect printing by warping some parts. When the temperature is too high, the extruded layers melt excessively and this can lead to sagging or sagging of the print.

For best results, the printing temperature should be between 200 and 230°C when printing with PLA filaments. Furthermore, the ideal temperature can also vary depending on the nozzle size and printing speed. So, do some test printing to find the best temperature for your 3D printer.

Adherence to the Plan

Good bed adhesion is very important when printing PLA or any other filament. Bed adhesion refers to the ability of the molded plastic to remain glued to the bed construction plan as the printing proceeds. If the printed plastic peels off, the print may be affected.

To improve your printer's bed adhesion, you can:

- Clean the print bed with isopropyl alcohol before printing.

- Apply bed adhesives, such as hairspray or glue sticks.

- Adjusting the bed temperature is a good choice to improve adhesion. In the case of PLA, it is advisable to maintain the bed temperature at 60°C to obtain better adhesion.

- Poor alignment can be the cause of weak bed adhesion. For this reason, before printing, check whether the bed is level or not.

- Excessive print speed can dislodge the plastic print, so slowing down should be sufficient.

- Changing the surface of the bed is another great solution to increase the grip of the bed if the methods above don't work.

Some popular bed surface solutions for printing with PLA filaments are:

Blue Ribbon

It's kind of like duct tape. It is used to cover the print bed and improve adhesion. These tapes are generally porous, making them perfect for filaments like PLA. The best blue ribbons Made to improve the adhesiveness of the print bed, they are heat resistant.

Kapton tape

These tapes work as a base layer and protect the surface of the print bed. For adhesion you need to use juice, glue, hair spray or similar products. The advantage of these tapes is that they are sold in large rolls. Therefore, only one layer is needed for the print bed surface. However, be very careful when rolling out the Kapton tape on the bed. In fact, it is possible for air bubbles to remain trapped under the tape and create creases.

PEI

THE PEI sheets they are great for printing various types of filament. Thanks to these sheets, you won't have to use adhesive sprays, clips or glues and you won't have to prepare the surface for printing.

Glass bed

A glass bed it is one of the best alternatives you can evaluate when it comes to the bed surface. Glass beds are strong, dense and durable, and their price is affordable. We recommend that you purchase carborundum glass. Carborundum glass, with a thickness of 3-4 mm, can withstand temperatures between 150 and 400 degrees.

PLA Printing Speed

Printing speed must be above 50mm/s when printing PLA filament. You can create aesthetically exceptional models if the printing speed is around 100 mm/s. However, high-speed printing can warp PLA. That's why you need to run tests using different print speeds. This will help you find the right print speed for your printer and filament. When printing PLA filament, it is ideal to print at a slower speed to ensure optimal results.

To print complex, detailed models, you need to slow down the print speed. However, if you need to print simple models, it is better to increase the speed. Increase extrusion speed to print faster. You can also use the print head acceleration feature to increase speed.

Post-Processing and Finishing Process

When the printed model is ready, the most important thing is to give it a shiny, shiny and realistic look. This process is called post-processing . You can distinguish the whole process into two categories: one is cleaning and the other is finishing.

Pre-sanding, sanding and smoothing are processes that belong to the cleaning category. Treatment and painting fall into the second category.

Pre-sanding

In this process you need sandpaper, pliers, tweezers and a toothbrush to smooth the surface of the print.

Sanding

Sandpapers are needed at this post-processing stage. Purchase 120 grit PLA filament sandpaper and do not use it on the corners or edges of the printed model. Sanding work is done to correct the deformity of the prints and can therefore be time consuming. The larger the print, the longer it will take to sand.

Smoothing

Smoothing is very important to achieve a glossy finish and simply sanding is not enough. Smoothing eliminates layer lines better than sanding can. There are many straightening techniques that can be used, but here we will talk about chemical straightening.

Chemicals like ethyl acetate are a good choice for smoothing PLA filaments. This chemical dissolves layer lines without having to intervene manually. Furthermore, this chemical substance does not damage the underlying layers.

Painting

In this process you will need two things: one is spray paint and the other is masking tape. The tape holds the print securely in place while you spray the paint. Spray paints come in bright colors and go very well with plastic.

PLA Filament Post-Processing Considerations

Post-processing is a very important step to perfect the appearance of the print, its durability and its functionality. Accordingly, you need to pay attention to this process. Below are some post-processing observations you should consider to ensure a better print finish:

- Post-processing techniques such as pre-sanding, sanding, or smoothing can change the size accuracy of a 3D print. To maintain it, be sure to use accurate software, calipers, calipers, or micrometers.

- Designing prints in subsets allows for better smoothing. This way you can work on smoothing each part individually.

- We recommend painting your 3D prints in a controlled environment. This eliminates the chances of contamination that can affect the paint.

- To avoid runs and voids, don't spray your PLA 3D prints too closely. Spraying from a far distance can cause the same problem, so find the right spot for best results.

- Make sure your 3D print is placed vertically before painting it.

- Wear appropriate clothing, masks and gloves for safety before spraying paint on your 3D prints. These paints are often toxic, flammable and risky.

Advanced Tips and Troubleshooting for Issues Related to Printing with PLA Filaments

The Temperature Is Too Low To Print

If the temperature is not optimal, the PLA filaments do not adhere, thus generating rough surfaces. This can also make some pieces brittle. Fix this problem increasing the temperature by 5°C . Try printing until you see that the layers stick together properly.

The Temperature Is Too High To Print

Excessive stringing or casting it means the temperature is too high to print. With PLA filaments, the higher the heat, the glossier the prints become. To avoid excess buildup, get the best layer cooling system. An adjustment of the printer's retraction settings can help with stringing. Reduce the temperature by 5°C if both methods prove ineffective.

If The First Layer Does Not Adhere

This can happen if the bed surface is not level or if the nozzle height is not adequate. Therefore, check these sections. If the distance between the work surface and the nozzle is not correct , the PLA filaments can move.

If the printed parts have roughness

This type of problem occurs when the printer is not receiving proper data, the PLA filament is of poor quality, or the retraction settings have not been adjusted. Use SDS card to solve this problem. Make sure you buy the best quality PLA filament and check that the retraction settings are correct.

Changing PLA Filaments

- Heat the extruder to 120°C if it is cold.

- If the extruder temperature reaches 90°C it begins to extract all the PLA filaments and raises the temperature to 200°C if there is a problem removing the PLA.

- Raise the temperature and fill the PLA filaments as always.

- Then slide the new colored filament through until you see nothing but the new color.

Common Problems Related to Printing with PLA Filaments

Bad Adhesion to the Bed

PLA must be immersed in water, which is where the extrusion problem arises. Drying the filaments solves the problem. Use a filament dryer or an oven. Additionally, reducing the print speed also helps. To avoid melting, keep the temperature below 50°C.

Stringing

Filament strings when the extruder reaches too high temperatures or the retraction settings are wrong. So, check that the settings are correct and lower the temperature if the problem is with the extruder.

Dots and Bubbles

Activate the coasting function so that the extruder turns off for some time. During this time the filament can cool down a little to ensure better printing. Additionally, optimize your retraction settings to prevent spots and bubbles from forming.

Deformation

By increasing the temperature of the bed and using adhesives and coatings, the deformation phenomenon can be avoided. Adjusting the first layer and applying anti-warping supports can also help.

PLA filaments are very widespread, so much so that they are the second most produced bioplastic. They are relatively cheap and easy to use. With the right print settings, PLA filaments can produce quality prints.

3digital.tech

3digital.tech