Meltio M600

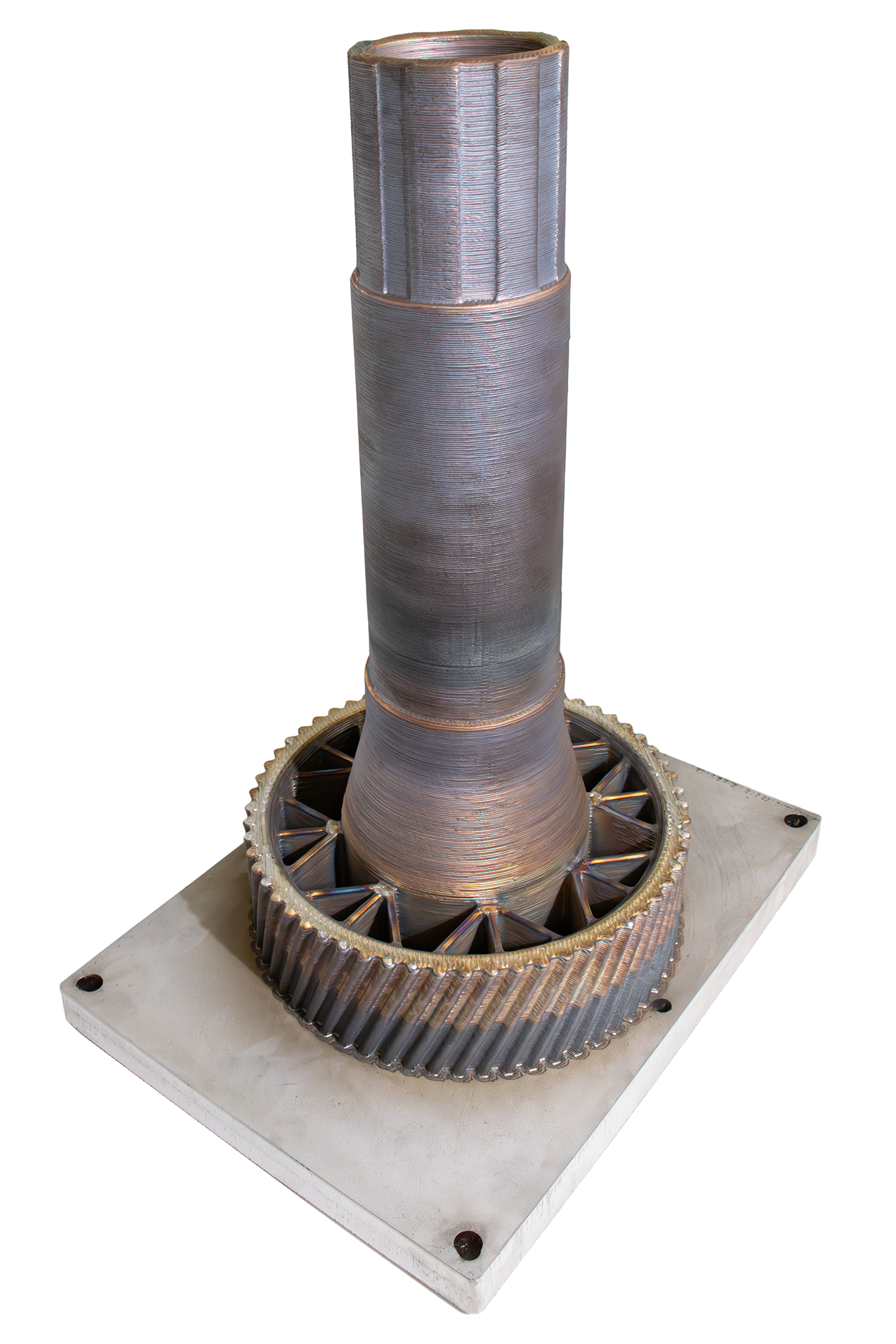

Industrial metal 3D printer

Expand your manufacturing capabilities with blue lasers, a large build volume, and a fully inert chamber for the best material properties. Printing is easier than ever with improved process control, advanced sensors and real-time monitoring that let you produce parts consistently 24/7.

Meltio M600, with its integrated 3-axis probing system and workholding solutions, is the ideal companion for your manufacturing operations.

The all-in-one printing platform.

Meltio M600 allows you to print large parts or a batch of small parts in a row, simultaneously. Improved process control for stability and repeatability.

Ready for production

Larger parts, higher deposition rate, wider material range, inert build chamber, lower maintenance and integrated job support solutions.

Reliable

Enhanced wire feeding system, fiberless deposition head, improved process control systems and much more.

Easy to use

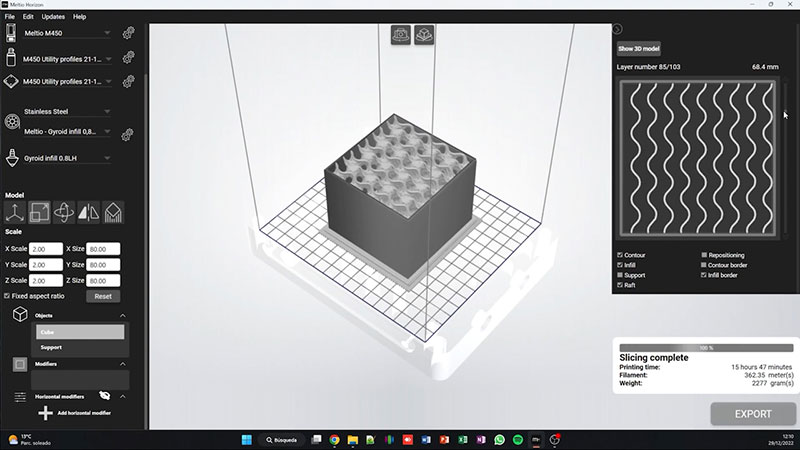

Minimized operator interaction thanks to advanced sensor solutions, simplified user interface, dedicated slicer and zero point clamping system.

Reduced maintenance

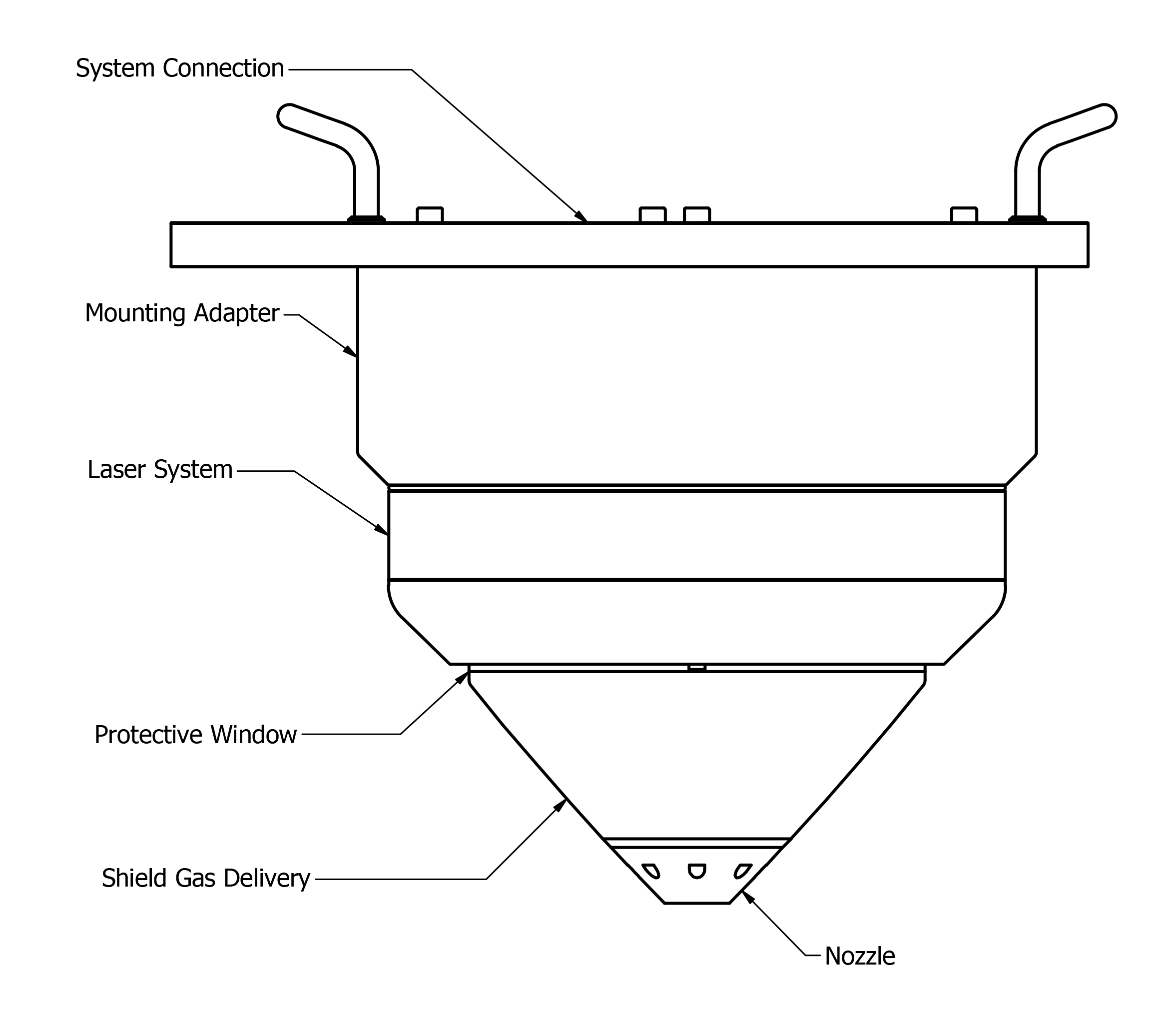

The newly designed deposition head eliminates the need for laser alignment, while the motion system has been improved to ensure maximum durability.

Blue is the new green.

The increased efficiency in power supply reduces electricity consumption, making it a cost-saving process, thanks to blue laser diodes.

Blue light

450nm light improves energy absorption and printing efficiency across the entire spectrum of metallic materials.

Hotwire compatible

The deposition head was developed to be used with an optional hot wire feed to increase deposition speed and enable the processing of more materials.

No calibration

Arrives aligned from the factory for maximum print repeatability and minimal maintenance.

High efficiency

Energy consumption per component is significantly reduced, resulting in a more environmentally friendly and cost-efficient process.

Technical specifications

Dimensions (WxDxH):

1050 x 1150 x 1950 mm

Envelope printing (WxDxH):

300 x 400 x 600 mm

System weight:

800-1000 kg (depending on options)

Movement system:

Servomotor Linear axis with absolute encoder on all axes

Filtering system:

3-stage chemical and particulate filtration included

Environment Control:

Check the O2 and humidity level

Laser Type:

9x direct diode lasers

Laser wavelength:

450 nm (Blue)

Total laser power:

1000W

Power Input:

400V three phase

Energy consumption:

4 – 6 kW Peak depending on options selected

Process control:

Closed-loop, laser and wire modulation

Touch probe:

Built-in automated XYZ touch probe

Attached:

Controlled and safe inert atmosphere for the laser

Interface:

USB, Ethernet, Wi-Fi

Cooling down:

Active water-cooled chiller included

Diameter of wire raw material:

0.8 – 1.2 mm

Coil of thread raw material:

BS300 or external wire drum

Wire materials

Stainless steels:

Excellent strength and corrosion resistance

Mild steels:

Economical and ductile, with unparalleled workability and weldability

Carbon steels:

High impact resistance, maintains hardness at high temperatures

Titanium alloys:

Maximum strength to weight ratio and corrosion resistance

Nickel alloys:

High versatility, exceptional resistance to heat and corrosion

Copper and aluminum:

Conductivity, corrosion resistance and light weight resistance.

Parameters under development.

Upgrades and accessories

Hot wire:

Programmable feeder that preheats the material to increase deposition speed

External thread drum connection:

Connects external wire drums to the M600, allowing the use of 100kg and 200kg material packs

Multiwire:

This option allows sequential 3D printing of up to 4 materials with very fast automatic wire changes

Zero point clamping system:

Quickly and precisely mate clamping plates to the M600 build bed for production