What are 3D printing technologies?

Source: 3dnatives.com

3D printing is a process of additive manufacturing based on the idea of converting a digital model into a three-dimensional solid object. Over the years, several 3D printing technologies, also called Additive technologies have been developed in the industry with the common feature of creating a physical model layer by layer.

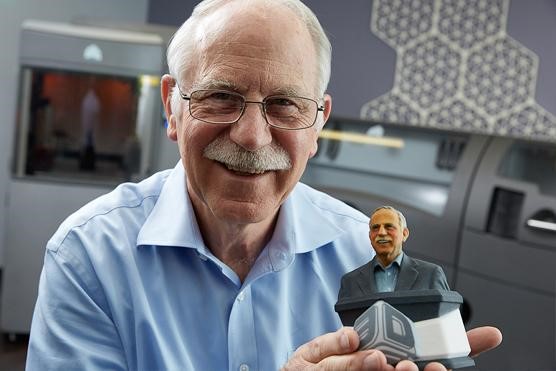

The origin of the concept dates back to the 1980s, when Dr. Kodama of the Nagoya Municipal Industrial Research Institute created a rapid prototyping technique capable of producing an object “slice by slice”. In 1984, a team of French researchers created a first patent that was then definitively abandoned a few years later. It was finally Chuck Hull, future founder of the giant 3D Systems, who obtained the first commercial patent in 1986 for a technique then called “stereolithography”. In 2016, the giant HP surprisingly announced its entry into the 3D printing market with a new proprietary technique called Multi Jet Fusion which combines additive technologies Binder Jetting and Material Jetting for the production of plastic parts.

This early development truly marked the beginning of what is now considered the fourth industrial revolution, offering applications in sectors as numerous and diverse as medicine, aeronautics, jewelry, and many others.

Development of additive manufacturing technologies

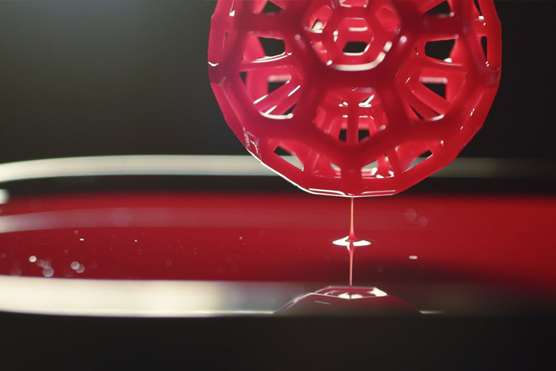

There stereolithography (SLA) is a technology that uses a liquid resin solidified under UV light as a 3D printing material. From this first discovery, new additive manufacturing techniques have emerged over the years. In 1988, Professor Carl Deckard of the University of Texas filed a patent for the Selective laser sintering (SLS) which is based on the fusion of a plastic powder with a laser. At the same time, Scott Crump, founder of the Stratasys group, was developing the first 3D printers using the extrusion of plastic filaments. This technique, patented under the name of Fused deposition modeling (FDM) , is one of the most popular 3D printing technologies today due to its ease of use and relatively low purchase cost.

Since the 1990s, additive manufacturing has continued to take off with the arrival of innovative technologies: Binder Jetting, invented by ZCorp, which uses a mineral powder, a binder and colored inks; PolyJet technology, created by the Israeli company Objet, in which the 3D printer deposits thousands of fine droplets of solidifying liquid photopolymers onto a tray and immediately polymerizes them using UV light. SLS, on the other hand, gave rise to metal additive manufacturing with the advent of additive technologies such as direct metal laser sintering (DMLS) , marketed by players such as Phénix Systems, SLM Solutions or Concept Laser, or the electron beam melting (EBM) developed by the Swedish company Arcam in the 2000s.

Despite the high level of competition, many players continue to enter the market, some improving existing processes and others developing original processes. The manufacturer EnvisionTec with DLP (Digital Light Processing) printing, the French company Prodways with MovingLight or Carbon3D with CLIP have for example developed technologies derived from stereolithography. In 2016, the giant HP surprisingly announced its arrival on the 3D printing market with a new technique called Multi Jet Fusion that combines powder assembly and material jetting for the additive manufacturing of plastic parts.

Today, however, it is metal that is emerging as the material of choice for printer manufacturers. Among the newcomers are BeAM Machines, XJet, Markforged, Fives AM, Desktop Metal, and AdMetalFlex, each of which has its own reasons: lower costs, shorter print times, diversity of compatible metals, etc. In 2020, the 3D printing market, including the sale of machines, printing materials, and associated services, was estimated at $17 billion.

The Evolution of 3D Printing Materials

The development of the 3D printing materials has been very rapid over the past few years. Some materials have improved over time, and others have developed or emerged with the arrival of new 3D printing technologies. From plastic to metal, to surprising materials like edibles, each material has specific characteristics and is often adapted to a particular technology.

Each 3D printing material is available in different formats, from resins for DLP and SLA technologies, filaments for FDM technologies or metal powders for L-PBF. New formats and materials are developed every day to allow the development of more resistant models and better print quality.

Currently, the 3D printing materials market is large and still growing. Many players are investing and betting on it. The 3D materials market is expected to reach $1.4 billion by 2021.