Guide to PLA for 3D Printing

Source: 3dnatives.com

the PLA ( polylactic acid ) is one of the plastic materials most used in the additive manufacturing industry. Invented in 1930 by chemist Wallace Carothers, who also developed nylon and neoprene, this material can be used in filaments or pellets for desktop 3D printers or industrial solutions. Unlike many other material options available on the market, PLA is considered a thermoplastic more sustainable because it comes from renewable sources such as corn starch, tapioca roots or sugar cane. This differentiates it from other industrial materials composed mainly of petroleum. Thanks to its more ecological origins, this material has always been among the most used in the 3D printing sector. Its use has in fact spread to a wide variety of sectors and applications. In this guide we will learn everything about this material: its characteristics, printing conditions, some of its applications, as well as the main manufacturers on the market.

Production and characteristics of PLA

As mentioned, the PLA It is obtained from organic and renewable resources such as corn starch, tapioca roots or sugar cane. In fact, the polymer is produced by fermenting one of these carbohydrate sources. More precisely, the natural product is ground to separate the starch from the corn, mixing it with acid or lactic monomers. With this mixture, the starch is split into dextrose (D-glucose) or corn sugar. Finally, the fermentation of glucose produces L-lactic acid, the basic component of PLA. The result is an ecological and renewable material that, depending on the temperature and humidity conditions, can become biodegradable.

PLA is made from sustainable materials such as corn starch.

In recent years, the sustainability of PLA filaments has been questioned, however. Perhaps because the term “biodegradable” often used to refer to this filament has led to confusion. In fact, although created from renewable materials found in nature, this does not necessarily make the material biodegradable. This material it can decompose, but only under certain aerobic conditions . For example, PLA can degrade rapidly if subjected to industrial composting; otherwise, it can take up to 80 years to decompose in the open air, becoming, like other plastics, therefore, polluting.

Another property of this material is that it is considered a non-Newtonian pseudoplastic fluid. This means that its viscosity (resistance to flow) changes depending on the stress to which it is subjected. Therefore, it does not have a defined and constant viscosity value, but varies according to the manufacturing conditions. In particular, PLA is a thin-shear material, which means that the viscosity decreases with the applied stress. To learn more, let's look at its usage characteristics and its behavior when used as a 3D printing material below.

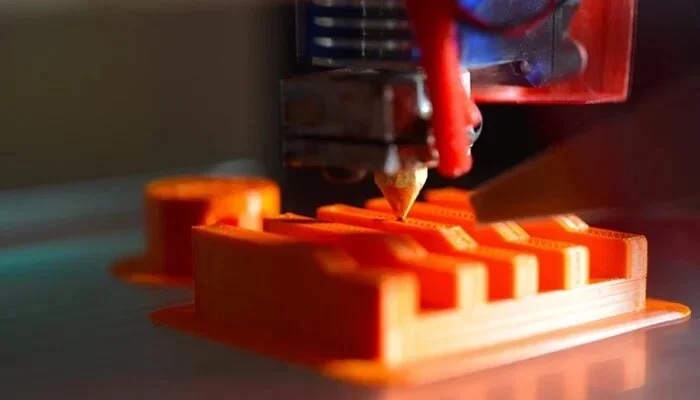

PLA in 3D printing

PLA is one of the most used materials in FFF 3D printing, especially by those who are new to the 3D industry, as it is very easy to print. It is usually found in filament form, but also in pellets or granules. Although the material supply source and the melting system vary depending on the PLA format (through an extruder for filaments or a tank for pellets), the characteristics of the material and the final parts do not vary from one type to another. However, in this article we will focus more on PLA in filament form, since it is the most common form in which this thermoplastic is usually found.

PLA is one of the most widely used thermoplastics in 3D printing (photo: BMI Lab)

This material is a semi-crystalline polymer with a melting temperature between 170-180°C , lower than ABS filaments which start to melt between 200 and 260°C. This means that when printing with PLA, there is no need to heat the print bed or have a closed print chamber. At the same time, the filament offers good performance, combining high printing speed with fairly sharp edges, provided the material is adequately cooled. In addition, the resulting parts tend to have very low deformability. The only downside is that PLA filament has a higher viscosity than other standard thermoplastics which, if you are not careful, can lead to clogging of the print head. In addition, the filaments have a shelf life of at least 1 year when stored at a temperature between 15 and 25°C. If we compare PLA with ABS, another of the most used thermoplastics in FDM 3D printing, we observe that, in general, the former does not have the same resistance and flexibility as the latter, but it is also less subject to deformations. However, it is always advisable to use PLA in parts that do not have a high mechanical complexity, as its processing is much simpler.

In terms of post-processing , PLA generally does not require complex steps. When removing the pieces, you may encounter problems with the adhesion of the first print layer. It is therefore recommended to use special adhesives on the print bed to facilitate the removal of the pieces. To improve the surface of the pieces, the user can sand them and treat them with acetone, if necessary. Supports, if used, can be easily removed with tweezers or dissolved if they have been used soluble support structures.

Applications

As mentioned, PLA is a relatively accessible and easy-to-use plastic for 3D printing, especially among makers. But that doesn’t mean it’s all about the benefits. Its properties mean that printed parts are fragile, not very resistant, and sensitive to sunlight and high temperatures. For this reason, it’s mostly used by beginners, especially for creating decorative elements, gadgets, and toys.

However, PLA is not limited to the maker world. Many industries also use this thermoplastic, for example for prototyping. This allows companies to save a lot of money, instead of going through the process of creating molds. Furthermore, although it is not the first option that people turn to, even sectors such as automotive can benefit from PLA filament. In this case, it can be useful for creating car accessories or even some dashboard elements.

PLA is popular among makers and for rapid prototyping (photo credit: Markforged)

However, it is important to note that PLA has a low glass transition temperature (temperature below which an amorphous material behaves as a glassy solid), which makes it unsuitable for applications where higher temperature resistance is required. Also, for industries such as food, it is not advisable, for example, to use this thermoplastic to create cups containing hot liquids. However, it is safe for contact with food, which is why it is widely used in packaging.

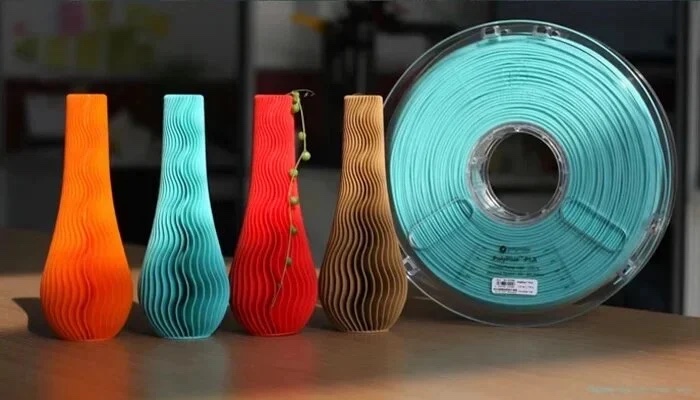

PLA Manufacturers and Price for 3D Printing

As one of the most popular materials in 3D printing, almost all material manufacturers today offer PLA filaments or pellets in their product range. These include Polymaker, Recreus, Smart Materials or BASF through its Forward AM brand. It is also worth noting that FDM 3D printer manufacturers often offer their own filaments. There are many PLA manufacturers, such as UltiMaker, Stratasys, Prusa or Zortrax, among others.

As for the price of PLA filament, it can currently vary depending on the colors and characteristics sought. Hybrid filaments, such as wood filament or fiber-reinforced filaments, significantly increase the price. However, the price of a standard filament is generally between 20 and 70 euros per kilogram. Finally, as already mentioned, there are also 3D printers that can print with pellets, a form of material that is more affordable than filament, especially because it is not processed.

https://3digital.tech

https://3digital.tech