What is thermal creep in 3D printers?

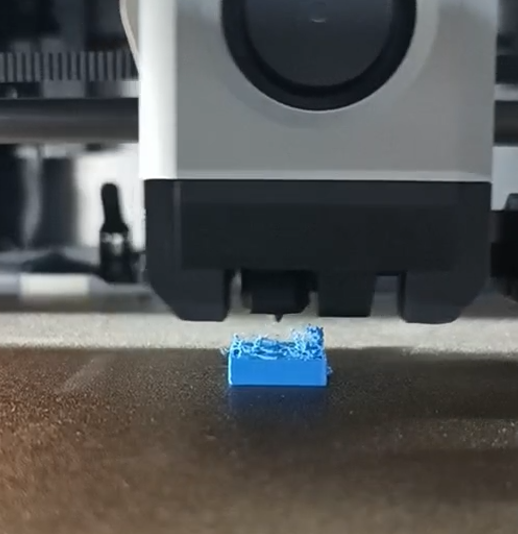

Heat creep is a common term used in 3D printing to refer to the phenomenon of gradual deformation of filaments caused by prolonged stress at high temperatures. During the 3D printing process, filaments undergo different heating and cooling temperature conditions, and heat creep can lead to issues such as dimensional changes and reduced strength of the finished print, which can affect the accuracy and overall performance of the finished product. Therefore, understanding and controlling heat creep is critical to ensuring the quality and reliability of printed parts.

Main causes

The occurrence of thermal creep is mainly related to the temperature and the properties of the filament.

Temperature

Room temperature

- Chamber Temperature : 3D printers use a heating system to maintain the chamber temperature to prevent rapid cooling and warping of the filaments during printing. The correct chamber temperature ensures the stability of the filaments during printing, but if the chamber temperature is too high, it may cause the filaments to soften during printing, which increases the risk of thermal creep.

- Heatbed Temperature : In 3D printing, the heated bed is usually heated to a certain temperature to increase the adhesion of filaments during printing and reduce shrinkage caused by cooling. However, if the heated bed temperature is too high, thermal creep may occur at the bottom during cooling.

Outside temperature

- Seasons : In the hot summer, even if the internal temperature control system of the printer is working properly, the high external temperature can cause the filaments in the heated area to soften more, triggering thermal creep. This makes the filaments softer and more deformable, and they do not flow well inside the extruder, increasing the risk of clogging the extruder. At the same time, excessively low temperatures in winter can cause a large difference between the temperature of the chamber and the external environment, affecting the cooling speed of the prints. The filaments can cool too quickly during printing, which can lead to uneven shrinkage of the filaments, creating stress concentrations and increasing the risk of thermal creep.

- Temperature Control in Post-Printing Process : The post-printing process (e.g. heat treatment and annealing) is usually performed in externally heated devices (e.g. ovens, kilns, or heat treatment devices) and is designed to improve the performance of filaments. During this process, the print is exposed to relatively high temperatures. As a result, the lack of an adequate cooling or stabilization step in the post-printing process can further exacerbate the phenomenon of thermal creep in filaments.

Filament Properties

The softening temperature ( or heat distortion temperature ) is the temperature at which a filament begins to soften and lose its original shape when heated to a certain temperature. It directly affects the flow behavior of filaments in a high temperature environment.

- Filaments with low softening temperatures are more susceptible to heat creep. Because these filaments become soft or begin to lose their original shape at relatively low temperatures, they are more likely to deform plastically at high temperatures, increasing the risk of heat creep. For example, PLA, PVA, and TPU softening temperatures are below 60°C and can warp, bend, or kink at high temperatures.

- In contrast, filaments with higher softening temperatures are less susceptible to heat creep and maintain good stiffness and shape stability at high temperatures, resulting in a lower risk of heat creep at relatively high temperatures. For example, PA and PC, with softening temperatures above 150°C, maintain good stiffness and shape stability at high temperatures and have a very low risk of heat creep.

Common problems

Extruder and hotend registration

Thermal creep causes filaments to become softer and more fluid at higher temperatures, which tends to build up or deposit inside the nozzle and heated area, resulting in a coarser or completely clogged nozzle inner diameter. At the same time, deposits caused by thermal creep can also cause clogging of the hotend channels. These buildups and deposits impede the normal flow of filaments, which can lead to clogging issues with the extruder and hotend.

Reduced print quality

Due to thermal creep, filaments become softer and more fluid at high temperatures. Softened filaments do not cure effectively during printing, resulting in weakened adhesion between layers and the formation of voids or holes. At the same time, the expansion and deformation caused by thermal creep result in an irregular internal structure of the printed part, which compromises its integrity and strength and reduces the overall print quality.

How to avoid heat creep?

How to avoid extruder/nozzle clogging due to filament softening caused by thermal creep?

- Open the door and remove the cover : When printing filaments with low softening temperatures (such as PLA, PVA, and TPU), open the front door or remove the top cover moderately to help lower the chamber temperature and cool the filaments. In particular, temporarily opening the door or cover can be a short-term solution when you observe excessive softening of the filaments or other issues during printing.

- Ensure that the ambient print temperature remains stable : Drastic temperature fluctuations can lead to uneven cooling of prints during printing, which increases the risk of heat creep. In general, the ambient print temperature should be maintained between 20°C and 25°C. To this end, you can use air conditioners, heaters, or ambient temperature sensors to monitor and adjust the internal temperature to ensure that it is maintained within the appropriate range.

How to avoid thermal creep (e.g., too rapid cooling due to large differences in ambient temperature, non-uniform cooling, etc.) leading to model deformation?

- Create a closed printing environment : When printing filaments with high softening temperatures (e.g. PA and PC), it is recommended to maintain a closed environment to keep the temperature stable, avoiding creep and warping due to uneven temperatures. It is recommended to always set the chamber temperature at least 10°C lower than the softening temperatures of the filaments.

- Select the appropriate heated bed temperature : Set the temperature according to the recommended heated bed temperature range for the filaments you are using. Setting the correct heated bed temperature improves adhesion between the filaments and the heated bed and reduces warping and shrinkage caused by uneven cooling during printing. Especially when printing filaments with low softening temperatures, excessive heated bed temperatures can cause thermal creep and should therefore be kept within the recommended range.

- Slow down the cooling rate : In heat-treating equipment (e.g., ovens, kilns, or heat-treating devices), gradually reduce the heating temperature (e.g., 5°C per hour). This gradual reduction helps the filaments adjust to the temperature change and reduces the possibility of thermal creep. Also, to ensure adequate cooling time, avoid removing prints immediately after heat-treating so that the filaments can stabilize at a lower temperature.

- Appropriate drying temperature : During the drying process, make sure the temperature is set within the appropriate range for your filaments . Excessive temperatures can cause the filaments to soften excessively, increasing the risk of thermal creep. Follow the recommended drying temperatures for each type of filament.

Other considerations

- To further help you choose the right filaments and optimize your printing environment, check out the filament guide on our blog for more information about filaments, which will help you avoid heat creep more effectively.

- When printing filaments with low softening temperatures, if the ambient temperature is extremely low (for example, 5°C-10°C), you can close the front door and install the top cover to increase the chamber temperature, which can also prevent warping. If the extruder or hotend still clogs after following this procedure, slightly opening the front door allows the internal hot air to circulate with the cooler external air, which helps lower the chamber temperature and stabilize the temperature distribution, thus reducing clogging caused by overheating or uneven heat.

- It is recommended that you regularly check your printer's heating elements and cooling system to ensure they are working properly. This helps prevent thermal creep caused by equipment failure and ensures the quality and consistency of your prints.

https://www.instagram.com/3digital.tech/

https://www.instagram.com/3digital.tech/