Laser Classification and Laser Safety: Tips You Need to Know

From enabling precise medical procedures to playing a vital role in printing and manufacturing, lasers have become an integral part of various markets. But do all of these lasers work the same? Are they all safe?

The answer is no; while they all adhere to the fundamental definition and principle of a laser, they are not the same thing. A laser is a device that emits light through a process of optical amplification. In simple terms, it focuses light into a concentrated beam, providing a level of precision and control unmatched by other light sources.

Differences in lasers, especially in their safety, are defined by laser classes. These classes help identify potentially harmful lasers and suggest the necessary precautions that should be taken when using them.

In this article, we will explore the different classes of lasers and mention how safe each one is. We will also highlight a Class 1 Laser Product , which is renowned for its safety.

Why Laser Grading is Important

As we know, lasers emit concentrated light. Direct exposure poses significant risks to the eyes and skin. The laser classification system informs users about the necessary safety measures and precautions. This helps prevent accidents and ensure safety in places such as medical facilities and manufacturing plants.

Each class of laser requires specific levels of control and protective measures. Lower class lasers require basic precautions, while higher class lasers require rigorous controls and protective devices.

In addition to personal safety, laser classification promotes responsibility and awareness of laser use . It helps create safer environments and encourages responsible use of laser technology in various industries.

Understanding Laser Classes

Lasers are classified based on their power/energy and the potential harm they can cause. A term that is overused when describing laser classes is Maximum Permissible Exposure (MPE) . This is the highest level of laser radiation that a person can be exposed to without any harmful effects or biological changes to the eye or skin.

According to IEC 60825-1 , lasers are mainly divided into four classes; some classes have subclasses. Let's explore each of them:

Class 1 laser

Class 1 is a very low power laser, and is safe for everyone under normal conditions. There is no possibility of exceeding the MPE. Class 1 laser is used in particular in laser printers and CD players.

Class 1M lasers are safe for all conditions of use except when passed through magnifying optics such as microscopes and telescopes. They can be potentially hazardous when viewed with optical instruments. Examples include fiber optic communications devices.

It is pertinent to mention that a Class 1 laser product does not imply that the laser inside the machine is inherently low power or Class 1. In fact, a Class 1 laser product could house a laser of any class, including high power Class 4 lasers. The classification of the product as Class 1 is due to the casing and design that ensures that the user cannot access the laser light during normal operation.

Class 2 laser

Class 2 indicates visible lasers with low power, less than 1 mW. They are safe because the blink reflex will limit exposure to no more than 0.25 seconds. It is assumed that the exposed person will react to the bright light and avoid staring into the beam.

Class 2M lasers are again safe due to the blink reflex unless an optical instrument is used. If used, this may exceed the MPE. Laser pointers and some rangefinders contain Class 2 lasers.

Class 3 laser

Class 3R lasers are continuous wave (CW) and have a power range of 1 to 5 mW. Pointing devices and scanners are common examples. The perceived risk is low and the likelihood of injury is minimal under normal conditions of use. However, there is a potential risk if the user deliberately stares into the beam.

Class 3B lasers are moderately powerful (5 to 500 mW). They are commonly used in spectrometry and medical applications. Again, direct exposure to the beam can be hazardous to the eyes, and diffuse reflections can also be harmful. Protective eyewear is usually required.

Class 4 laser

Class 4 lasers are highly powerful (>500 mW) and are commonly used in medical surgery, laser cutting, welding and micromachining. These lasers can cause serious eye and skin injuries and can also pose a fire hazard. They can also cause damage from direct and scattered light. Protective measures, including goggles and training, are essential.

| Laser Courses |

Energy | Security level | Example | Protective measures |

|---|---|---|---|---|

| Class 1 / 1M | Very low power | None required | Printers / DVD Players | Avoid use with optical instruments |

| Class 2 / 2M | < 1mW | Safe with caution | Distance Finding Equipment | Avoid direct exposure to eyes |

| Class 3R | 1 – 5mW | May cause eye damage if viewed directly | Pointing devices, scanners | Avoid direct exposure to eyes |

| Class 3B | 5 – 500 mW | May cause immediate damage to eyes and skin | Spectrometry, Medical Research | Protective glasses are required |

| Class 4 | > 500mV | High risk; may ignite combustible materials | Industrial laser machines | Protective eyewear and additional safety measures are required |

Why are Class 1 laser products safer?

Class 1 laser engravers are distinguished by their intrinsic safety features and versatile functionality. The enclosed design of these engravers ensures that there is no risk of exposure to harmful laser radiation during normal use. It also prevents any potential fire hazard by containing the laser beam in a controlled environment.

These products are often equipped with an automatic shutdown mechanism . This mechanism is activated if someone opens the case during operation, preventing any direct interaction between the user and the laser. It greatly improves user safety.

Some Class 1 laser products also come with filter covers . These covers block the harmful rays emitted by the internal laser. So even with a high-powered Class 4 laser inside, the user is still protected from exposure and harm by the product design.

Therefore, many prefer Class 1 laser products for various laser applications. They offer a safe and reliable option compared to open laser machines.

xTool S1: The Safest Diode Laser Cutter

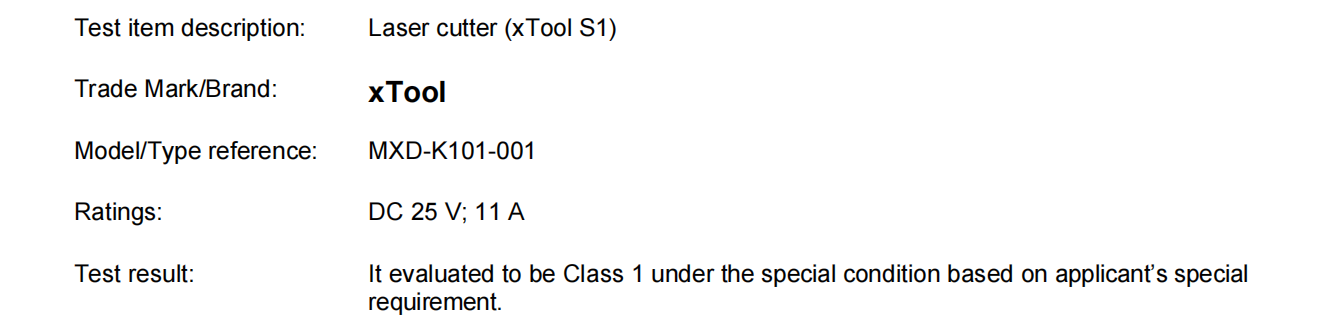

xS1 is the market leader in laser safety, symbolising protection with its Class 1 certification. This rating has been verified by third party testing organization , SGS.

This enclosed machine integrates advanced safety features, such as a double laser light filtering cover , which eliminates the need for safety glasses.

It is not only safe but also powerful, boasting a 40W high-power diode laser . With this, it is capable of precisely cutting and engraving a variety of materials. It combines efficiency and safety, with optimal air quality maintenance, rapid response to anomalies and an automatic shutdown function for accidental opening during processing.

Additionally, the S1 enhances ease of use with innovative features such as two-point positioning for precise real-time measurements. The machine is a perfect blend of safety, power and innovation, designed for small businesses, DIY enthusiasts, designers, craftsmen, educators and woodworkers.

Laser Safety Guidelines: Do's and Don'ts

Laser machines, as mentioned, are mostly Class 4 lasers and not all machines are certified as a Class 1 laser product. Therefore, it is essential to take extreme care when using them. To help you use laser cutting and engraving machines safely, we have compiled a concise list of dos and don'ts.

What to do

- Correct material setting: Use appropriate parameters to ensure work perfection and avoid potential safety risks.

- Use a laser enclosure for protection: An enclosure surrounding the entire laser will eliminate the risk of accidental injury and ensure debris stays inside the enclosure. Most xTool Class 4 machines are fully enclosed, with the exception of the D1 Pro open diode laser. However, we have designed a D1 Enclosure Set to prevent harmful radiation from escaping, ensuring your safety.

- Prioritize eye protection: Always wear laser goggles that cover the wavelength range of the laser machine. This protective measure is essential to avoid any accidental exposure that could potentially damage your eyesight. It is recommended to use xTool Professional Safety Glasses , especially when working with the xTool D1 Pro.

- Use Air Assist for the best cut: Using Air Assist can prevent smoke, distortion and discoloration. It ensures clean cuts and smooth finishes. Try using the xTool Air Assist Set , which offers an exceptional flow rate of 30 L/min to keep cuts and the work area clean.

- Clean up the work area after each project: After each project, clean up the work area of waste, debris, and dust. This practice is essential to reduce the risk of fire and exposure to harmful fumes or particles.

- Ensure adequate ventilation: Since lasers produce smoke and fumes during operation, a proper ventilation system is required to purify the smoke before it is released into the atmosphere. For example, you can use the xTool Smoke Purifier which performs 3-stage filtration and keeps the noise level below 55dB.

- Read the manual carefully: Before using the laser, carefully read the safety and operating instructions.

What not to do

- Do not leave the machine unattended: Never leave the laser unattended while it is operating to avoid the risk of fire or other accidents.

- Do not ignore safety protocols: Do not ignore or disregard the built-in safety features and protocols of the laser equipment. These features are designed to prevent accidents and ensure safe operation.

- Do not ignore warning signs: Always pay attention to all warning signs and labels on laser equipment. These warnings are there to guide users in the safe use of the equipment.

- Do not expose eyes or skin to laser beam: When working with open laser machines, avoid any direct exposure of eyes or skin to the laser beam. Such exposure can cause serious injury and long-term damage.

Conclusion

Laser classes are established to inform users of the inherent risks and necessary safety measures associated with each type of laser. The advanced xS1 Instrument is designated as a Class 1 laser product.

However, for those open laser machines like the D1 Pro, xTool provides a complete Safety Kit with a case to ensure added safety for all users. This dedication to safety underscores xTool's mission to provide cutting edge, reliable and safe laser technology to users across the spectrum.

https://www.instagram.com/3digital.tech/

https://www.instagram.com/3digital.tech/