Why the Phantom 4 RTK is indispensable in surveys

The short answer:

The Phantom 4 RTK it represents the perfect synchrony of price, level of precision and reliability.

An integrated real-time kinetic sensor geotags each image as it is captured, so when aerial data is corrected against ground control, surveyors are able to achieve centimeter accuracy. Not only do they achieve an accuracy of 1/10 feet (3cm), but they do so every time they fly.

Because it's significantly less expensive than alternative options, it's a low-risk investment for businesses and operations of all sizes, particularly those that couldn't afford to start a drone program earlier.

In 2013, DJI introduced the world to the Phantom , a durable quadcopter that has brought an air of professionalism to a predominantly recreational market. Around this time, people outside the aerial photography community have begun to explore use cases for the objectivity and visibility that a bird's eye view presents.

From there, the Phantom series of drones has become the workhorse of the construction, aggregates and waste management sectors for years. The latest version, the drone The Phantom 4 RTK (P4RTK) , which is DJI's first survey-focused UAV, has only amplified DJI's importance to the surveying community.

But what made the Phantom 4 RTK so revolutionary? The answer: an anonymous cylinder that sits on top of the drone, marking images with positional data in real time.

Here's how DJI's RTK-enabled drone changed the detection paradigm.

The difference that RTK makes

With the introduction of the Phantom 4 RTK (P4RTK) , DJI has brought survey workflows closer to real-world accuracy than ever - we're talking accuracy down to 1 / 10ft (3cm).

To obtain centimeter accuracy, the P4RTK uses TimeSync technology to coordinate its camera and RTK receiver, ensuring that the most accurate geospatial information is tagged on every single image. In addition, TimeSync centers the positioning data on the camera's optical center, which helps ensure the accuracy of the data during processing.

Real-time geotagging, plus corrections from a base station on the ground, means unprecedented reliable accuracy for your drone surveys.

Now, surveyors can gauge what is collected from the sky versus what is collected on the ground to form a single source of location truth.

What else do you get with the Phantom 4 RTK?

Superior image quality : the P4RTK combines a one-inch 20-megapixel CMOS sensor; a mechanical shutter that improves the capture of moving objects; and a wide-angle lens optimized for aerial shooting with a focal length of 24mm, to give you crisp, consistent images every time you fly.

Intelligent Flight Modes : Users can direct the flight of the P4RTK simply by touching a point on the remote control screen, drawing a path with your finger or telling it to take the most direct route “home” to the base station. Alternatively, users can pre-load a predetermined flight path by uploading a KML file or use ActiveTrack mode to automatically track designated objects.

A remote controller designed for professionals : Includes a microSD card slot, high-quality speaker and hot-swappable batteries, so users don't lose connection to their drone if they need to change batteries during flight.

Accuracy of 3 cm for each detection

In the past, construction sites juggled between speed and precision; rapid data collection meant compromising accuracy. Because surveying took a significant amount of time (and a surveyor's time came with a significant amount of dollars), construction sites weren't polling frequently enough to extract all the useful progress tracking metrics they wanted.

Surveyors found themselves in a stalemate with their data collection methodology, a battle they conceded out of necessity. Walking a construction site, surveying points, establishing ground control - these things took days, sometimes weeks, depending on the surface.

The Phantom 4 RTK has dismantled that delicate balance between quality and rhythm to reduce detection times to a few hours, without sacrificing quality.

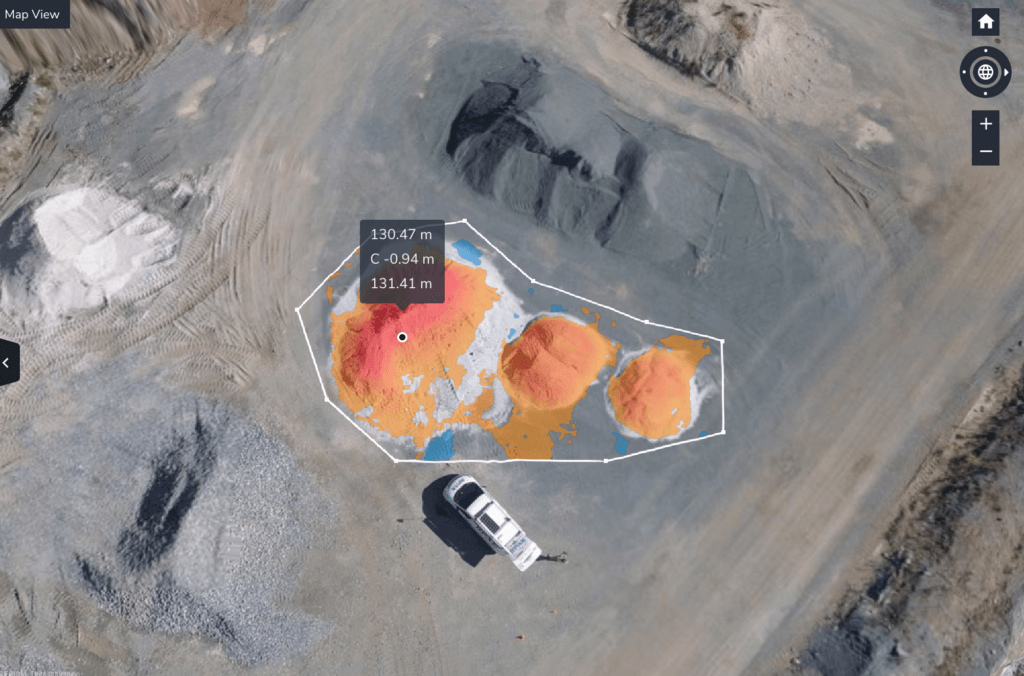

Today, surveyors get near real-time data as often as they want to fly a drone, with an accuracy of up to 3cm.

Once bandwidth is restored, surveyors can finally turn their attention to their strength: site analysis, using the collected data to make observations on efficiency and progress.

Because the Phantom 4 RTK paved the way for PPK

The P4RTK inspired Propeller to go where no one has ever been before, a place where hardware and software came together in fully integrated harmony, completely freed from compatibility issues.

To complete the drone workflow puzzle, DJI and Propeller joined forces in the fall of 2018, bringing a seamless flyover processing workflow to market. That's it, Propeller PPK It has been realized.

Propeller PPK combines the P4RTK with 1) AeroPoints, our high-precision “smart” ground control points, and 2) Propeller Platform, a cloud-based application for processing, mapping, measuring and sharing airborne data. When we blend these elements together, they form a single site management solution that is easy for new users to integrate into their workflow.

With more consistent ground control, you get more accurate data. And with more accurate data, you have the ability to remove surface layers and become strategic with material movement, risk assessment, and team collaboration.

The integration of AeroPoints into survey workflows also means less time traveling to busy and dangerous workplaces, leaving GCPs.

The Phantom 4 RTK it has not only helped surveyors do their jobs more efficiently and with greater accuracy. It enabled Propeller to provide customers with the tools they needed to unite (and define) the next generation of shipyards.

With less time on site, drone operations managers, who typically have other duties ranging from machine control to modeling, can focus more on using the collected data to improve efficiency and progress.

Where do we go in the future?

The survey professional is only part of a very complex network of individuals - there are foremen, customers, contractors, merchants, and the list goes on. They may have been the first air data gatekeepers, but now, Propeller's primary users are linking all their moving parts together using 3D models made with drones.

On its own, DJI brought consistency and accessibility to an otherwise erratic workflow, providing construction, harvesting and mining sites with the milestones they needed to reduce information silos and overcome age-old data collection challenges.

https://www.instagram.com/3digital.tech/

https://www.instagram.com/3digital.tech/